Manufacturing method for seabed photoelectricity composite rope with split conductor in huge cross section

A technology for optoelectronic composite cables and split conductors, which is used in cable/conductor manufacturing, power cables with shielding/conducting layers, power cables, etc. High quality and safety, tight arrangement and combination, good transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

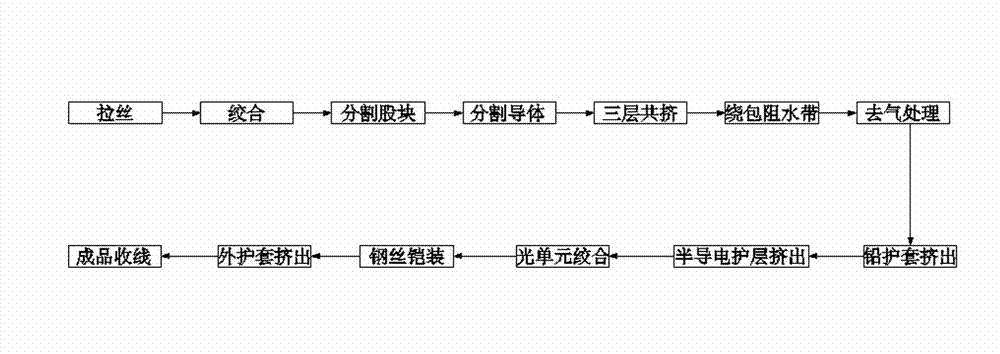

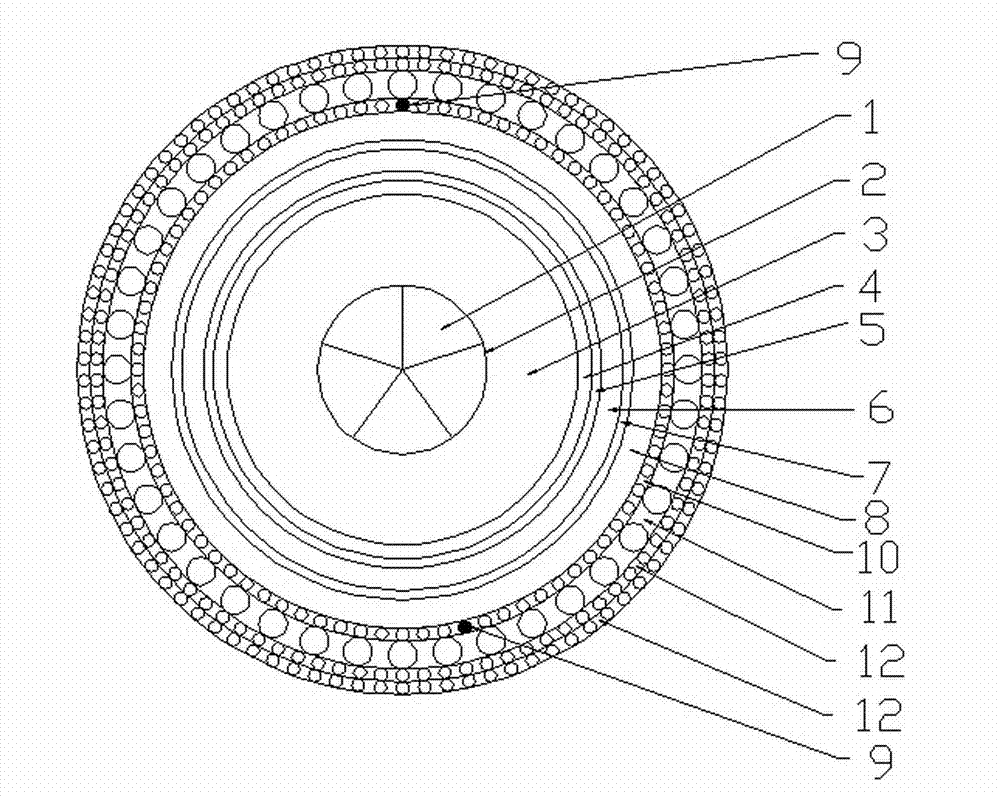

[0037] A method for manufacturing a subsea photoelectric composite cable with super-large cross-section split conductors, comprising the following steps: wire drawing—strandizing—splitting strands—splitting conductors—three-layer co-extrusion—wrapping water blocking tape—degassing treatment—lead sheath extrusion - Extrusion of semi-conductive sheath - Stranding of optical unit - Steel wire armor - Extrusion of outer sheath - Finished wire take-up, of which:

[0038] The wire drawing refers to drawing an electrical round copper rod through a large drawing machine into a round and smooth copper wire. The electrical round copper rod is preferably used as the raw material for drawing, but it is not limited to this method.

[0039] The stranding means that the copper wire made after the wire drawing process is twisted by a stranding machine to obtain a cross-sectional area of 500mm. 2 circular conductors, wherein the twisting speed of the stranding machine is controlled at 3m / min...

Embodiment 2

[0055] The implementation method of this embodiment is basically the same as the above-mentioned embodiment, and its difference is:

[0056] The stranding means that the copper wire made after the wire drawing process is twisted by a stranding machine to obtain a cross-sectional area of 500mm. 2 5 circular conductors, wherein the twisting speed of the twisting machine is controlled at 5m / min.

[0057] The split conductor 1 is a conductor formed by cabling 5 split strands by using a horizontal cable forming machine, wherein the cabling speed of the horizontal cable forming machine is controlled at 14rpm.

[0058] The lead sheath extrusion refers to that the cable core made after the degassing process enters the pay-off turntable of the lead pressing machine through the large-diameter transfer turntable with retractable function, and the lead sheath is extruded by the lead pressing machine. cover 6, and coat asphalt on the lead sheath 6 to form an asphalt anti-corrosion layer...

Embodiment 3

[0064] The implementation method of this embodiment is basically the same as the above-mentioned embodiment, and its difference is:

[0065] The stranding means that the copper wire made after the wire drawing process is twisted by a stranding machine to obtain a cross-sectional area of 500mm. 2 5 circular conductors, where the twisting speed of the twisting machine is controlled at 4m / min.

[0066] The split conductor 1 is a conductor formed by cabling 5 split strands by using a horizontal cable-forming machine, wherein the cable-forming speed of the horizontal cable-forming machine is controlled at 13 rpm.

[0067] The lead sheath extrusion refers to that the cable core made after the degassing process enters the pay-off turntable of the lead pressing machine through the large-diameter transfer turntable with retractable function, and the lead sheath is extruded by the lead pressing machine. cover 6, and coat asphalt on the lead sheath 6 to form an asphalt anti-corrosion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com