Automatic winder for inductor

A technology of inductors and winding machines, applied in the manufacture of inductors/transformers/magnets, circuits, coils, etc., can solve problems such as low efficiency, low positioning accuracy, inconvenient operation and hidden dangers, and achieve convenient adjustment of positioning angle, Simplified control program and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

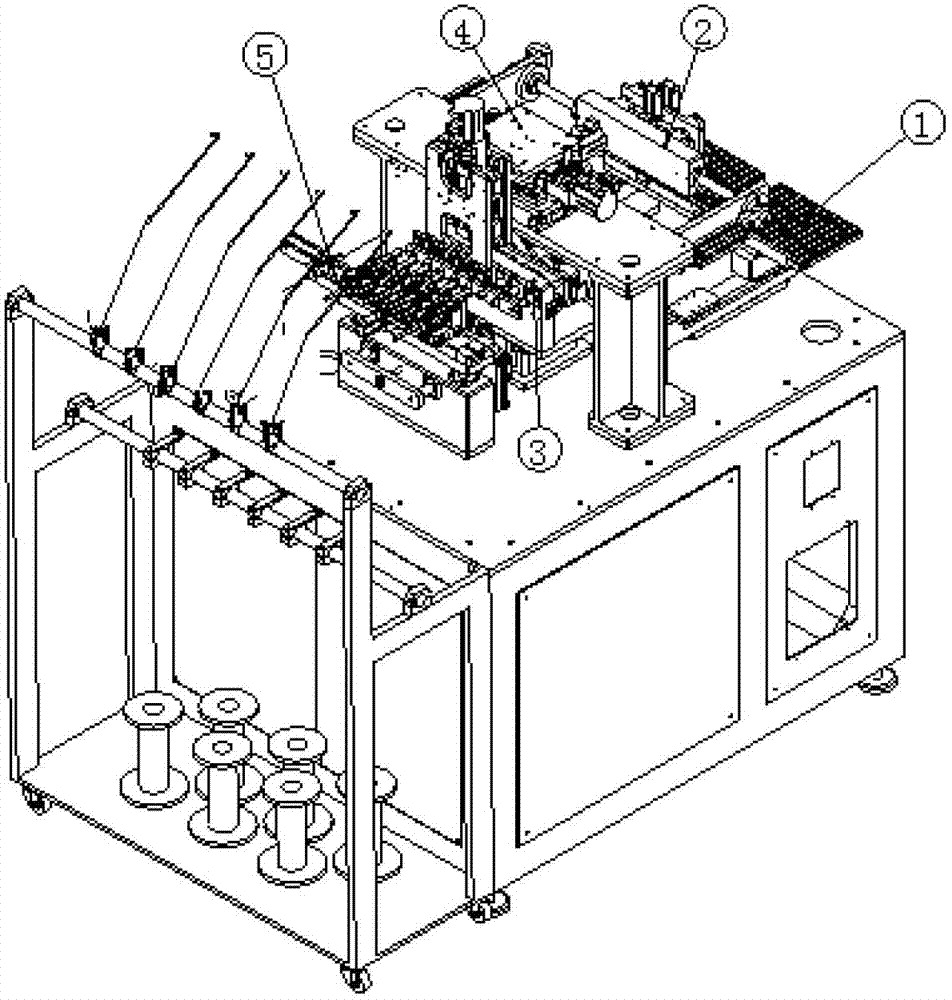

[0021] In general, figure 1 It shows the structure of the six-axis automatic winding machine for SMD inductors according to the first embodiment of the present invention. It should be noted here that although as a preferred embodiment, the six-axis automatic winding machine for SMD inductors is described in specific examples However, this is only for illustrative purposes, and the present invention is not limited thereto. It should be understood by those skilled in the art that the present invention can also be applied to such as three-axis, four-axis, five-axis, seven-axis, eight-axis In the automatic winding machine with any number of axes according to the design requirements, the automatic winding machine of the present invention is not limited to SMD inductors, but can be applied to any inductor for winding.

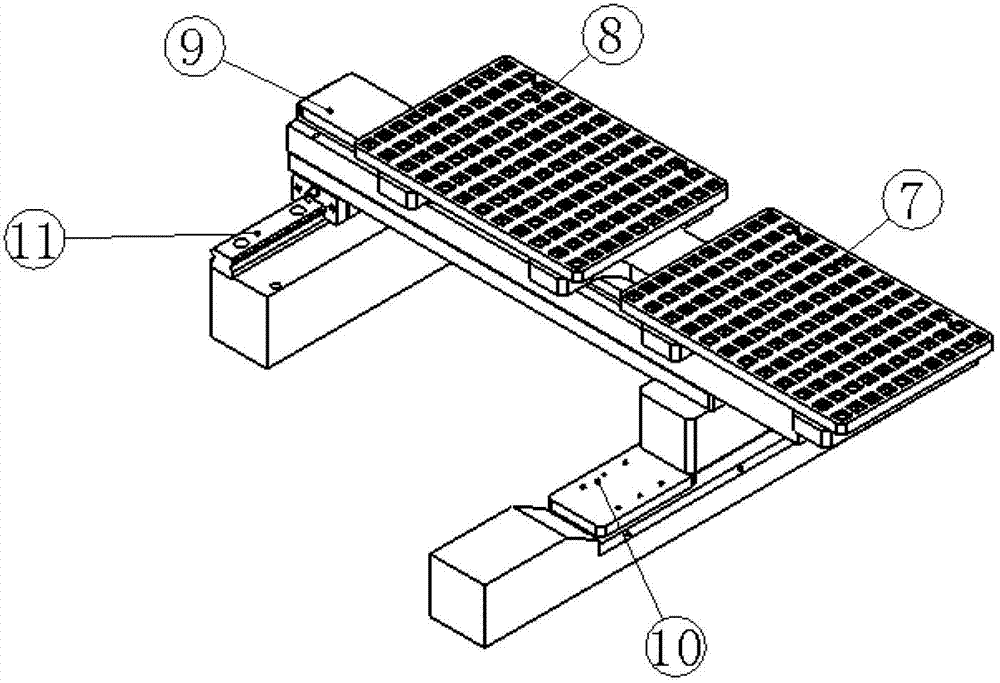

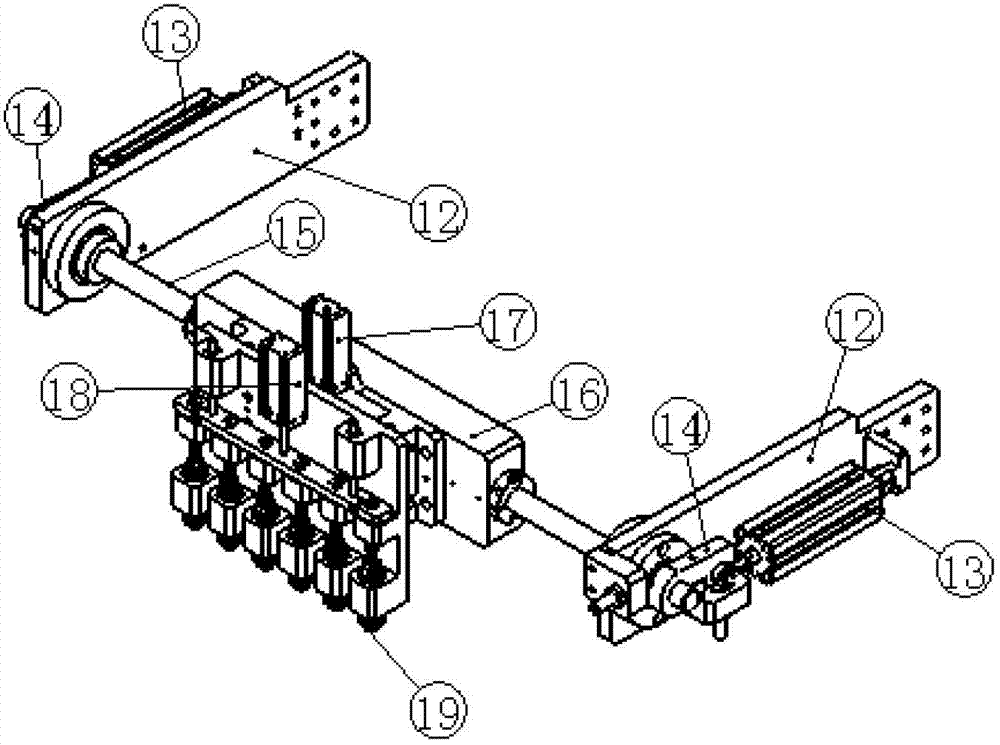

[0022] in such as figure 1 As shown, the six-axis automatic winding machine for SMD inductors of the present invention includes an automatic pallet unit 1, an autom...

Embodiment 2

[0037] The structure of the SMD inductor six-axis automatic winding machine of the second implementation of the present invention is as Figure 7 shown. The parts and functions of the automatic wire winding machine of this second embodiment are basically the same as those of the first embodiment, and the same units have also adopted the same reference numerals, and the difference is only in order to make the winding process Even tension control, the automatic winding machine in the second embodiment of the present invention can also preferably include winding tension control unit 6, such as Figure 8 shown.

[0038] Figure 8 Shows the winding tension control unit 6 of the SMD inductor six-axis automatic winding machine according to the second embodiment of the present invention, and the winding tension control unit 6 includes a bottom plate 58, a bracket 59, a lead plate 61, and a tensioner 62 . Among them, preferably also include wire barrel 60, and place the enameled bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com