Automatic meat cutting and shashlik forming machine

A meat cutting and stringing technology, which is applied in the direction of processing meat, meat processing equipment, slaughtering, etc., can solve the problems of restricting the popularization and application of automatic meat cutting and stringing machines, low production efficiency, slow meat stringing speed, etc., and achieve market application. And the effect of broad economic prospects, low manufacturing and use costs, and convenient maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

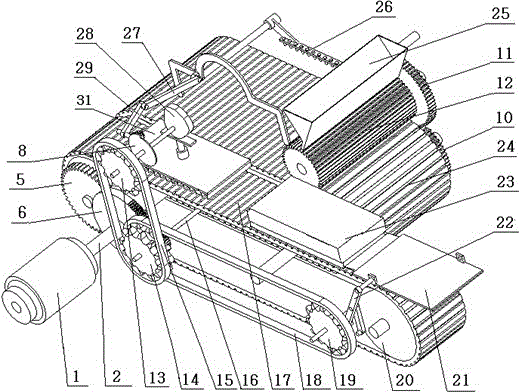

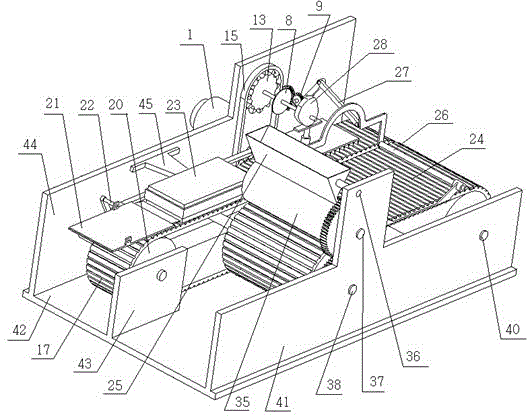

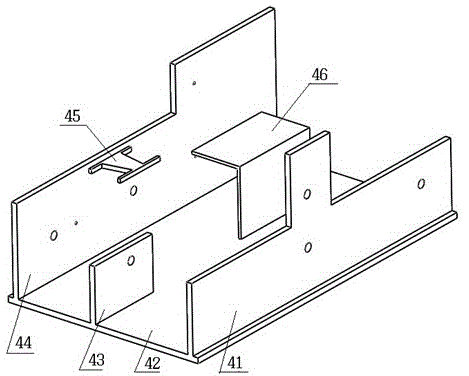

[0038] Embodiment 1: a kind of automatic meat cutting machine of the present invention, its structure is as figure 1 , 2 Shown in and 3, comprise transmission mechanism, meat-cutting mechanism, lottery mechanism, sign-pushing mechanism and frame. see figure 2 , the transmission mechanism, the meat cutting mechanism, the lottery dividing mechanism, and the lottery pushing mechanism are all installed in the frame. Rack see image 3 , is made up of frame right side plate 41, bottom plate 42, support plate 43, left side plate 44 and top plate 46.

[0039] The transmission mechanism is composed of a power source 1, a belt drive, a chain drive and a gear drive, the power source 1 is a combination of a motor and a reducer; there are two belt drives, a crawler belt 17 drive and a conveyor belt 24 drive; the chain drive is also two One is a vertical chain transmission composed of upper sprocket 13, lower sprocket 14 and chain A15, and the other is a horizontal chain transmission c...

Embodiment 2

[0045] Embodiment 2: For the general transmission mode of the automatic meat cutting and skewering machine of the present invention, see Figure 4 , its working process: adopt artificially to first pack meat pieces and meat strips of different sizes into a rectangular uncovered meat box 23, and freeze at a low temperature of 2°C; the uncovered meat box is fixed upside down on the meat box fixing frame 45 Under the action of gravity, the whole rectangular piece of frozen meat will automatically fall on the clean crawler belt 17; start the power source 1, and the power source output shaft 2 will transmit the decelerated power and rotating speed to the incomplete on the power source output shaft. Gear A4 and incomplete gear B6. The intermittent motion of the conveyor belt of stringer of the present invention is referring to Figure 5 , for the lottery movement of the lottery agency, see Image 6 , the feed and retract movement transmission of the cutter refer to Figure 7 , re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com