Ultra-fine grained nickel-titanium alloy root canal file and preparation method thereof

A nickel-titanium alloy, ultra-fine grain technology, applied in the direction of tooth nerve/root treatment tools, protective layer, medical science, etc., can solve problems such as poor cutting efficiency of nickel-titanium root canal files, and achieve good hardness and wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

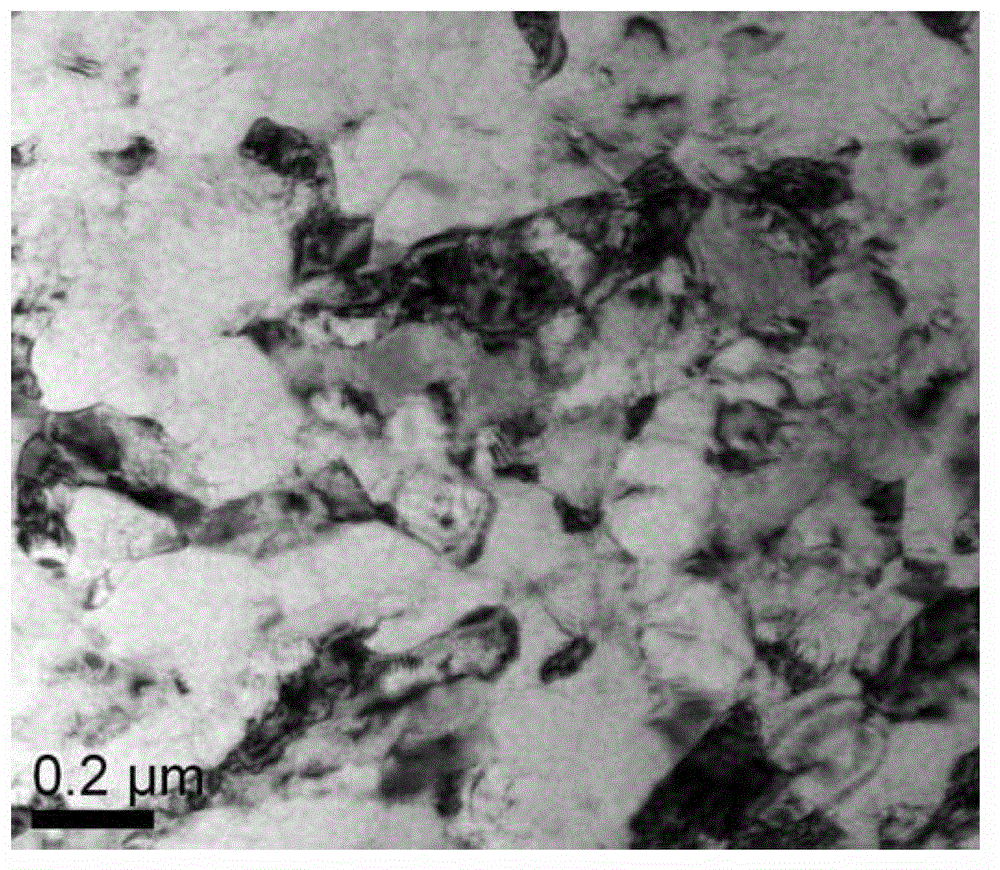

[0025] Embodiment 1: In this embodiment, the ultrafine-grain nickel-titanium alloy root canal file is made of ultrafine-grain nickel-titanium alloy with a particle size of 200nm-300nm.

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the ultra-fine-grain nickel-titanium alloy root canal file is made of ultra-fine-grain nickel-titanium alloy with a particle size of 260 nm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the preparation method of the ultrafine-grain nickel-titanium alloy root canal file in this embodiment is as follows:

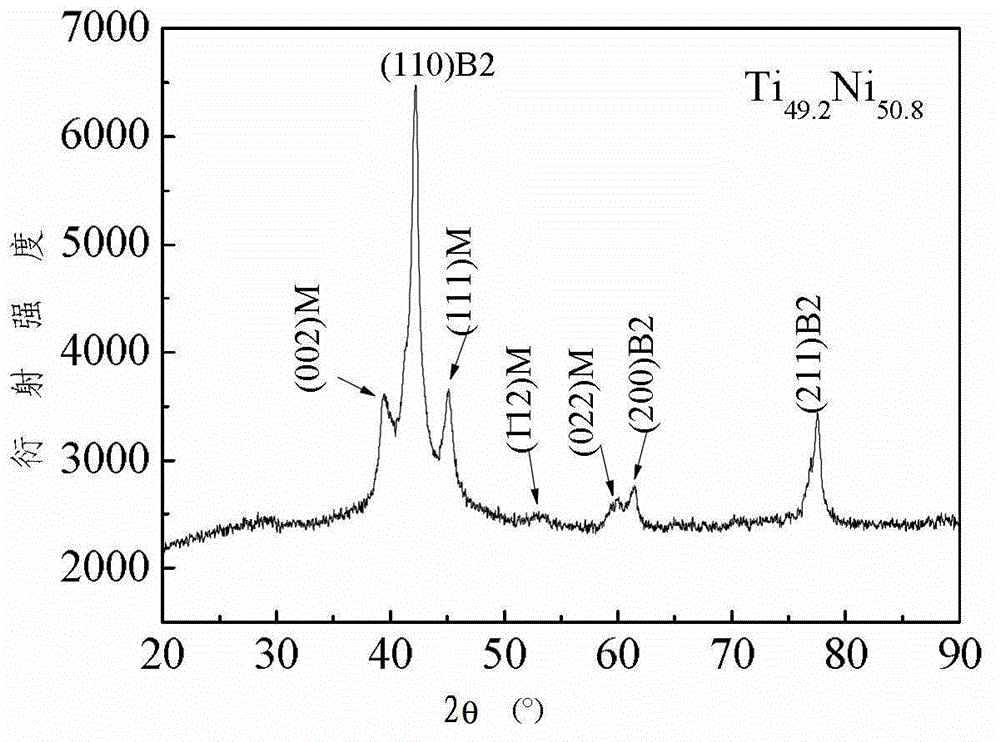

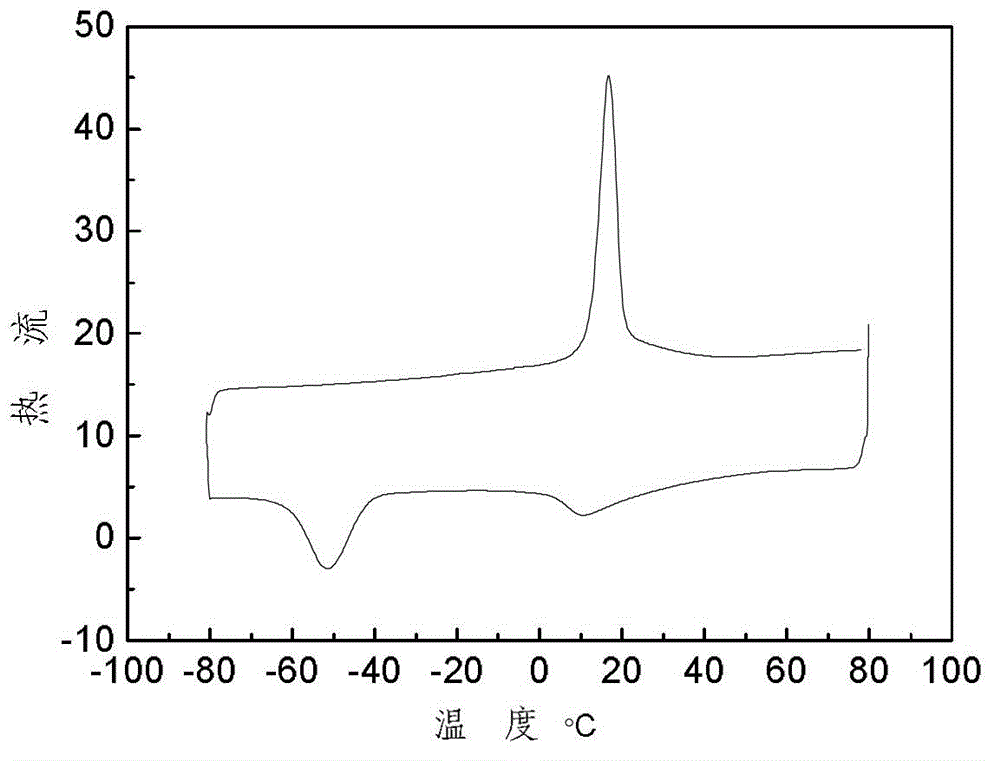

[0028] 1. Nickel-titanium alloy ultra-fine grain treatment: Cut the nickel-titanium alloy ingot with a Ti atomic percentage of 48-52% into a round rod with a diameter of 20mm and a length of 100mm, and then use the method of equal diameter angular extrusion to The round rods pass through the mold with two channels with angles of 90° and 120° respectively, and are extruded for 4-8 passes at 400-500°C, and then kept at 300-500°C for 30-60min to obtain ultra-fine grains. Nitinol rods;

[0029] 2. The preparation method of ultra-fine-grained nickel-titanium alloy wire: the ultra-fine-grained nickel-titanium alloy rod is used as lubricant with graphite emulsion, and the heating temperature is 600-700°C, the line speed is 15-25m / s, every Under the condition that the pass reduction is 0.04-0.01mm, the ultra-fine-grained nickel-tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com