Method for modifying rare earth of molecular sieve

A technology of rare earth modification and molecular sieve, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve high dispersion, improve stability, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

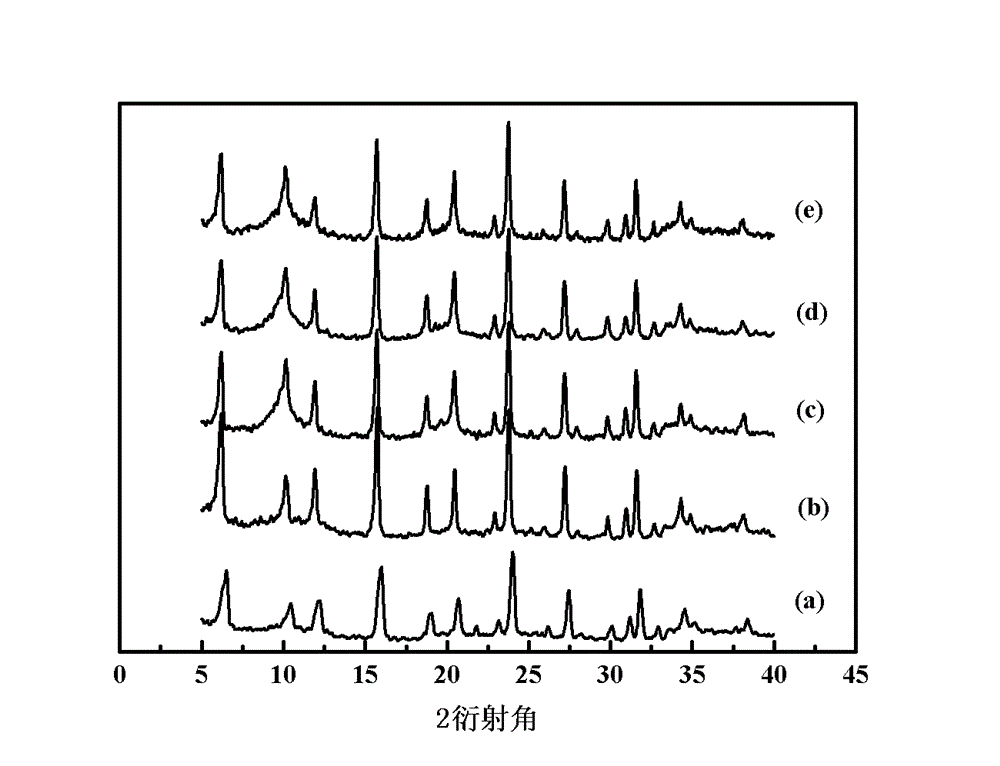

[0066] Add 5g of USY molecular sieve into 50ml of deionized water, stir evenly at 40°C, add 7.437g of zinc nitrate, 1.84g of lanthanum nitrate, and 3.19g of aluminum nitrate in sequence, stir for 0.5 hours after mixing, and add 1mol / L of Sodium hydroxide solution, adjust the pH value of the system to 6, stir for 4 hours under this condition, transfer to a high-pressure reactor, crystallize at 85°C for 24 hours, filter, wash and dry to obtain a Zn-Al-La / USY composite The material was heated at 1°C / min to 550°C, and calcined at this temperature for 2 hours to obtain a La-modified USY molecular sieve. marked as a.

Embodiment 2

[0068] Add 5g of USY molecular sieve into 50ml of deionized water, stir evenly at 20°C, add 7.437g of zinc nitrate, 2.71g of lanthanum nitrate, and 2.34g of aluminum nitrate in sequence, mix and stir for 0.5 hours, and add 1mol / L hydrogen at a rate of 1ml / min Sodium oxide solution, adjust the pH value of the system to 6, stir under this condition for 6 hours, transfer to a high-pressure reactor, crystallize at 85°C for 24 hours, filter, wash and dry to obtain a Zn-Al-La / USY composite material , the temperature was raised to 550° C. at 2° C. / min, and calcined at this temperature for 2 hours to obtain La-modified USY molecular sieves. marked b.

Embodiment 3

[0070] Add 5g of USY molecular sieve into 50ml of deionized water, stir evenly at 20°C, add 13.73g of zinc nitrate and 2.67g of lanthanum nitrate in sequence, mix and stir for 0.5 hours, add 2mol / L sodium hydroxide solution at a speed of 0.1ml / min, Adjust the pH value of the system to 6, stir for 6 hours under this condition, transfer to a high-pressure reactor, crystallize for 24 hours at 85°C, and obtain the Zn-Al-La / USY composite material after suction filtration, washing and drying, / min to 550°C, and calcined at this temperature for 2 hours to obtain La-modified USY molecular sieves. marked c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com