Core-adjustable variable-cross-section-tube ultrasonic condensation cyclone separator

A cyclone separator and supersonic technology, which is applied in the fields of expansion refrigeration and condensation separation of pressurized gas, can solve the problems of pressure energy loss, poor adaptability to changing working conditions, and reduced gas-liquid separation effect, etc. The effect of increasing and strong centrifugal separation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

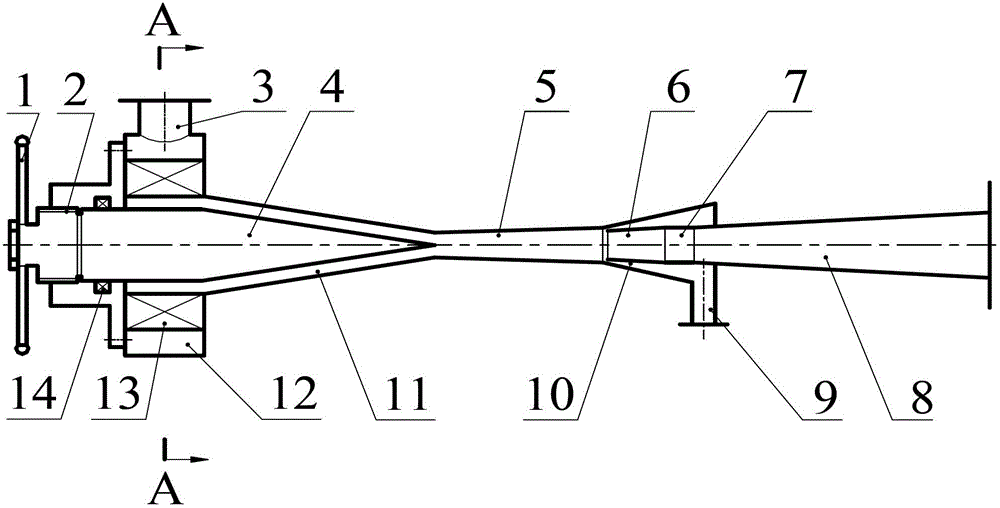

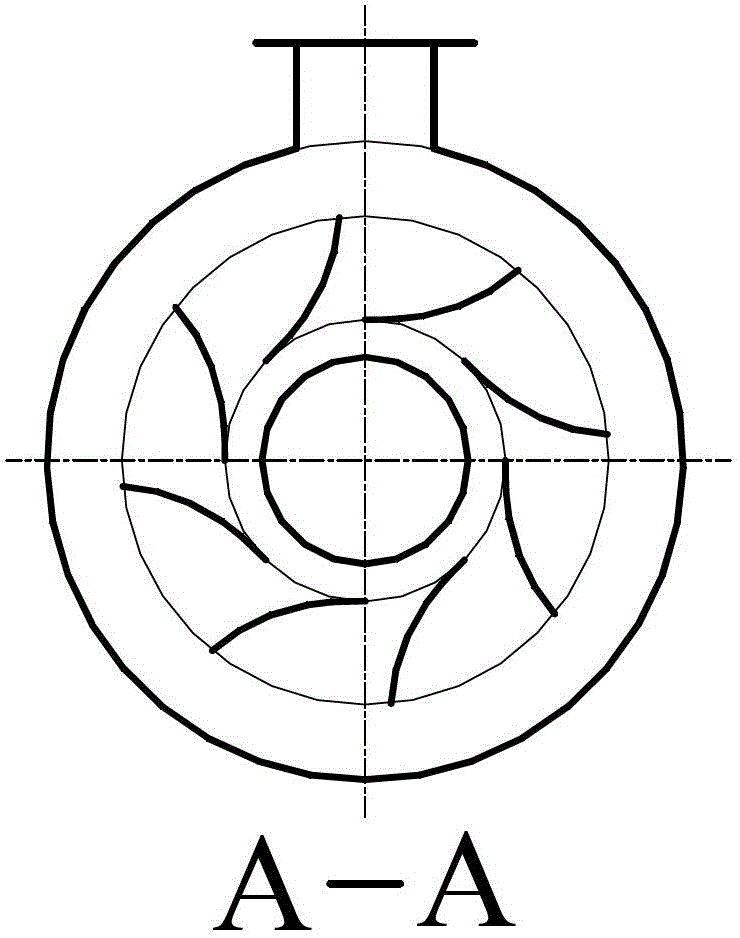

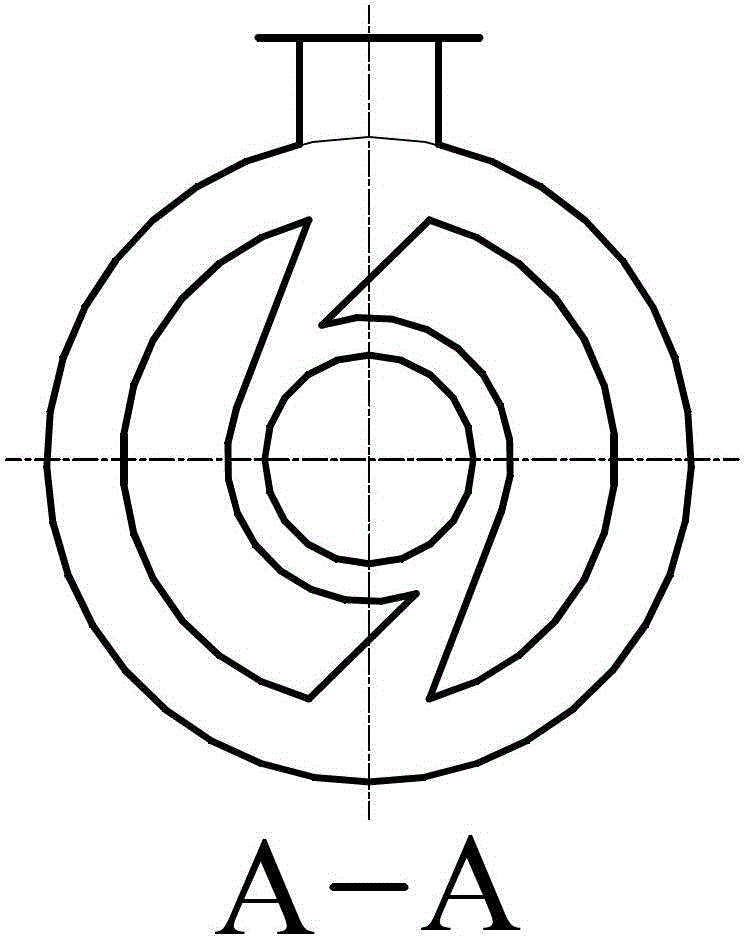

[0031] see figure 1, core-adjusting supersonic condensing cyclone separator, mainly composed of adjusting handle 1, screw inlet and outlet unit 2, gas inlet pipe 3, adjusting cone core 4, nozzle supersonic section 5, stabilizing cone section 6, nozzle deceleration straight Section 7, diffuser section 8, condensate outlet pipe 9, condensate outlet chamber 10, nozzle accelerating swirl section 11, intake buffer chamber 12, pre-swirl unit 13 and packing static seal 14.

[0032] In the central axis area of the accelerated swirling section 11 of the nozzle of the cyclone separator, place an adjusting cone core 4 whose axis coincides with the axis of the nozzle and whose position can move forward and backward, and turn the adjusting handle 1 to drive the screw in and out of the unit 2 , the adjusting cone core 4 is moved inwardly or outwardly along the axis, causing the cross-sectional area of the annular flow channel of the nozzle accelerating swirling section 11 to change cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com