Submerged arc welding wire suitable for welding cargo oil tank of crude oil tanker

A technology of submerged arc welding wire and ship cargo, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of low strength level of ship plate, large difference in mother plate composition and strength, unfavorable synchronization of corrosion resistance, etc., to achieve The effect of excellent low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

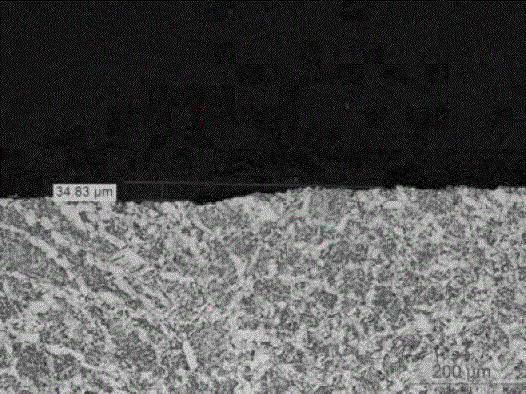

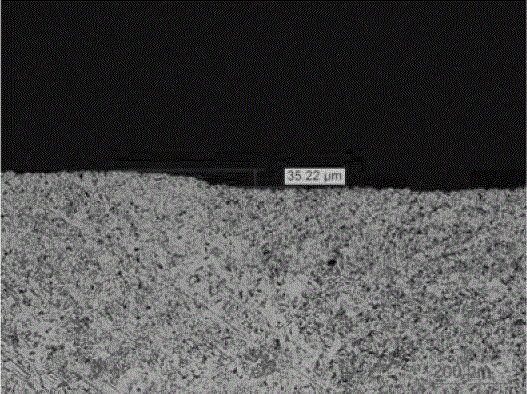

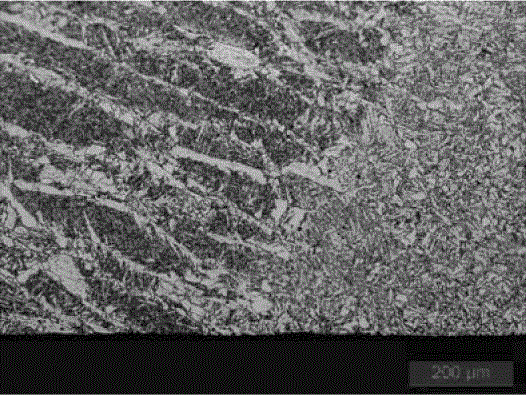

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0031] According to the scope of the chemical composition of the present invention, the vacuum induction furnace is used to smelt the welding wire steel of 7 furnaces. The examples are shown in Table 1, and the conventional submerged arc welding wire production process is used to draw the welding wire with a diameter of 4mm.

[0032] In addition, two kinds of more submerged arc welding wires used were selected as comparative examples 1 and 2.

[0033] Welding tests were carried out on the embodiments of the present invention, the flux was alkaline sintered flux, and the steel plates were corrosion-resistant ship plates for crude oil tankers and oil tankers developed by Baosteel. The mechanical properties of the welded joints are shown in Table 2. It can be seen from the table that the welding wire of the embodiment has excellent mechanical properties a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com