Ultralow temperature energy storage material composition

A technology of energy storage materials and compositions, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as crystallization temperature fluctuations, serious latent heat attenuation, performance discounts, etc., and achieve the effect of high melting latent heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

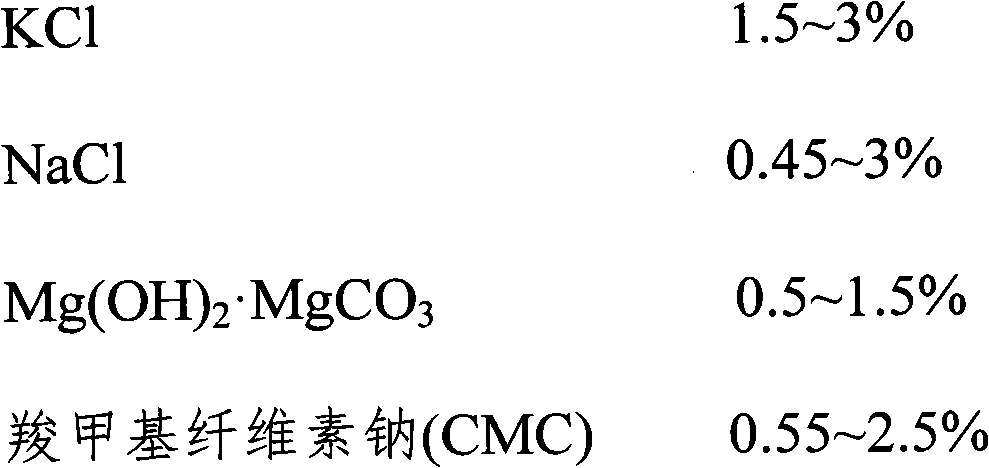

Method used

Image

Examples

Embodiment 1

[0015] Cool 1299 grams of water to 0-5°C, then add 260 grams of MgCl 2 , 325 g Ca(NO 3 ) 2 , 60 grams of NaCl, 10 grams of Mg(OH) 2 · MgCO 3 , 16 grams of sodium carboxymethylcellulose (CMC), and 30 grams of KCl were added to water successively, and the mixing and stirring time was 12 hours. 2 Add water and start to keep the solution temperature at -5-0°C, stir at a constant speed for 3 hours, then keep the solution temperature at -15-10°C, and store it statically below -20°C for 72 hours after the stirring is completed. According to the step cooling curve method, the crystallization temperature is -50.2°C, the supercooling degree is 2°C, and the latent heat of fusion is 301kJ / L. There is no obvious layering and precipitation under the condition of 48 hours and 20°C, and the system is relatively stable.

Embodiment 2

[0017] Cool 568.8 grams of water to 0-5°C, then add 200 grams of MgCl 2 , 166.7 g Ca(NO 3 ) 2 , 4.5 grams of NaCl, 15 grams of Mg(OH) 2 · MgCO 3 , 25 grams of sodium carboxymethylcellulose (CMC), and 20 grams of KCl were added to water successively, and the mixing and stirring time was 12 hours. 2 Add water and start to keep the solution temperature at -5-0°C, stir at a constant speed for 3 hours, then keep the solution temperature at -15-10°C, and store it statically below -20°C for 72 hours after the stirring is completed. According to the step cooling curve method, the crystallization temperature is -50.1°C, the supercooling degree is 2.1°C, and the latent heat of fusion is 302kJ / L. There is no obvious layering and precipitation under the condition of 48 hours and 20°C, and the system is relatively stable.

Embodiment 3

[0019] Cool 50.8 kg of water to 0-5°C, then add 21 kg of MgCl 2 , 21 kg Ca(NO 3 ) 2 , 2 kg NaCl, 1 kg Mg(OH) 2 · MgCO 3 , 1.2 kilograms of sodium carboxymethylcellulose (CMC), and 3 kilograms of KCl were added to water successively, and the mixing and stirring time was 12 hours. 2 Add water and start to keep the solution temperature at -5-0°C, stir at a constant speed for 3 hours, then keep the solution temperature at -15-10°C, and store it statically below -20°C for 72 hours after the stirring is completed. According to the step cooling curve method, the crystallization temperature is -50.3°C, the supercooling degree is 2°C, and the latent heat of fusion is 299kJ / L. There is no obvious layering and precipitation under the condition of 48 hours and 20°C, and the system is relatively stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of fusion | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

| Latent heat of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com