Method for separating and recycling valuable metals in powder rich in multiple metals of waste circuit board

A waste circuit board, separation and recovery technology, applied in the direction of improving process efficiency, etc., can solve the problems of complex metal enrichment powder components, immature supercritical technology, difficult deep separation and recovery of metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Low temperature oxidation melting

[0025] Take 5g of multi-metal enrichment powder shown in Table 1, weigh 21g of NaOH, NaNO 3 18g, mixed and placed at the bottom of a special crucible, sent to a well-type resistance furnace, and smelted at 450°C for 120min to obtain 43.44g of smelted product.

[0026] (2) Water leaching

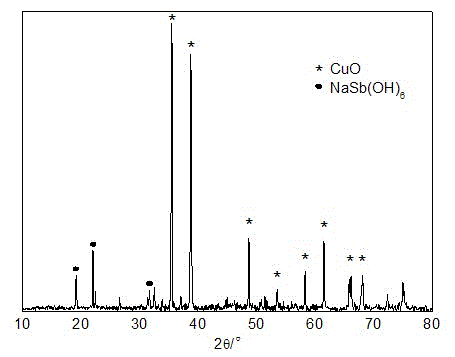

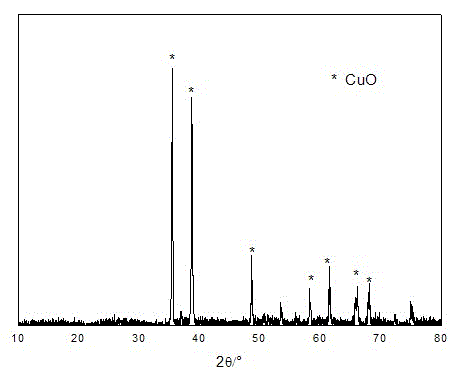

[0027] Cool the smelted product obtained in step (1), add 20mL concentration of 30% oxidant H 2 o 2 , add water until the liquid-solid ratio is 7, stir and leaching at 300r / min for 60min, and leaching temperature at 40°C; filter to obtain primary leaching slag and primary leaching liquid; copper and antimony are enriched in the primary leaching slag (see XRD for primary leaching slag figure 1 ); the leaching rates of zinc, tin, and lead in the leaching solution reach 98.00%, 95.61%, and 92.53% respectively, and adjusting the pH value of the solution and evaporating and concentrating can obtain ZnO, SnO 2 and PbO crystals, and extract zinc, t...

Embodiment 2

[0031] (1) Low temperature oxidation melting

[0032] Take 5g of multi-metal enrichment powder shown in Table 1, weigh 21g of NaOH, NaNO 3 15g, mixed and placed at the bottom of a special crucible, sent to a well-type resistance furnace, and smelted at 500°C for 90min to obtain 39.65g of smelted product.

[0033] (2) Water leaching

[0034] Cool the smelted product obtained in step (1), add 30mL concentration of 10% oxidant H 2 o 2 , add water until the liquid-solid ratio is 7, stir and leaching at 300r / min for 120min, and the leaching temperature is 40°C; filter to obtain a primary leaching residue and a primary leaching solution; copper and antimony are enriched in the primary leaching residue; zinc, tin, and lead in the leaching solution The leaching rates reached 96.63%, 95.93%, and 91.21% respectively. ZnO and SnO can be obtained step by step by adjusting the pH value of the solution and evaporating and concentrating. 2 and PbO crystals, and extract zinc, tin and lea...

Embodiment 3

[0038] (1) Low temperature oxidation melting

[0039] Take 5g of multi-metal enrichment powder shown in Table 1, weigh 18g of NaOH, NaNO 3 15g, mixed and placed at the bottom of a special crucible, sent to a well-type resistance furnace, and smelted at 500°C for 150min to obtain 37.72g of smelted product.

[0040] (2) Water leaching

[0041] Cool the smelted product obtained in step (1), add water until the liquid-solid ratio is 7, and feed about 0.5 L O 3 , 300r / min stirring and leaching for 60min, leaching temperature 40°C; filtering to obtain primary leaching slag and primary leaching solution; copper and antimony are enriched in the primary leaching slag; the leaching rates of zinc, tin and lead in the leaching solution reach 98.35% and 95.72% respectively , 90.13%, adjust the pH value of the solution, and evaporate and concentrate to obtain ZnO and SnO step by step 2 and PbO crystals, and extract zinc, tin and lead in the leach solution according to the prior art.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com