Energy saver system for air compressor

An energy-saving device and air compressor technology, applied in the direction of machine/engine, etc., can solve the problem of not much improvement of the air compressor system, and achieve the effect of solving frequent start and stop, improving impact and reducing room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

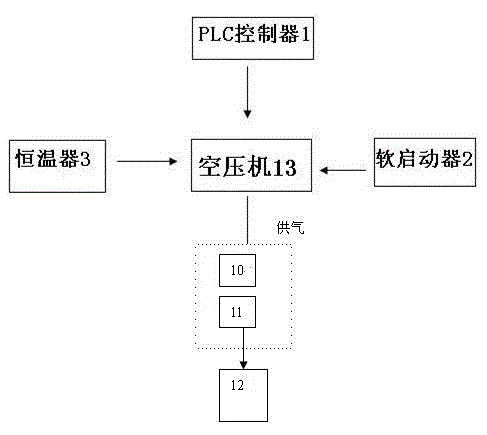

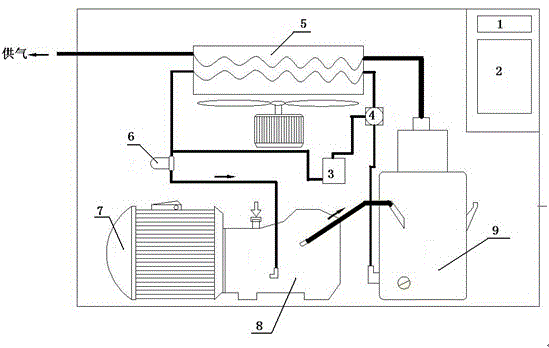

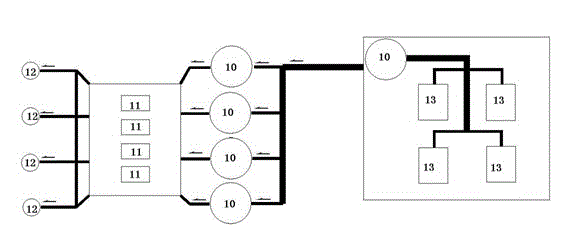

[0024] like figure 1 and figure 2 As shown in the system principle diagram of the present invention and the structure diagram of the air compressor, a screw air compressor energy saving system includes a PLC controller 1, an air compressor 13, a soft starter 2, a thermostat 3 and matching with the air compressor. wherein, in the air compressor 13, the compressor 8 is connected with the motor 7, the oil and gas are separated by the oil and gas separator 9, and the oil is returned to the compressor through the oil return pipeline equipped with the thermostat 3, Protect the temperature of the air compressor, so as to achieve the purpose of protecting the air compressor from running at low temperature; the compressed gas is supplied to the pipe network system after passing through the radiator 5; the operation of the air compressor 13 is controlled by the PLC controller 1; The soft starter 2 is set on the machine 11 to realize the soft start fast start;

[0025] The thermostat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com