LED (light-emitting diode) tube core with ZnO-micron and nano composite structure and preparation method thereof

A nano-composite, tube-core technology, applied in the field of optoelectronics, to achieve the effect of improving LED luminous efficiency, improving luminous efficiency, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

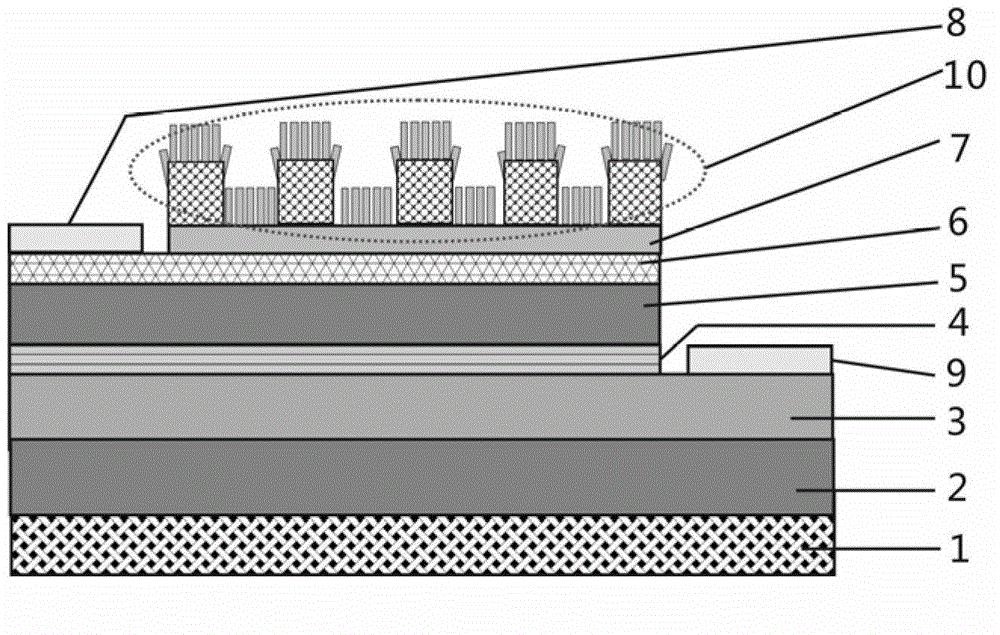

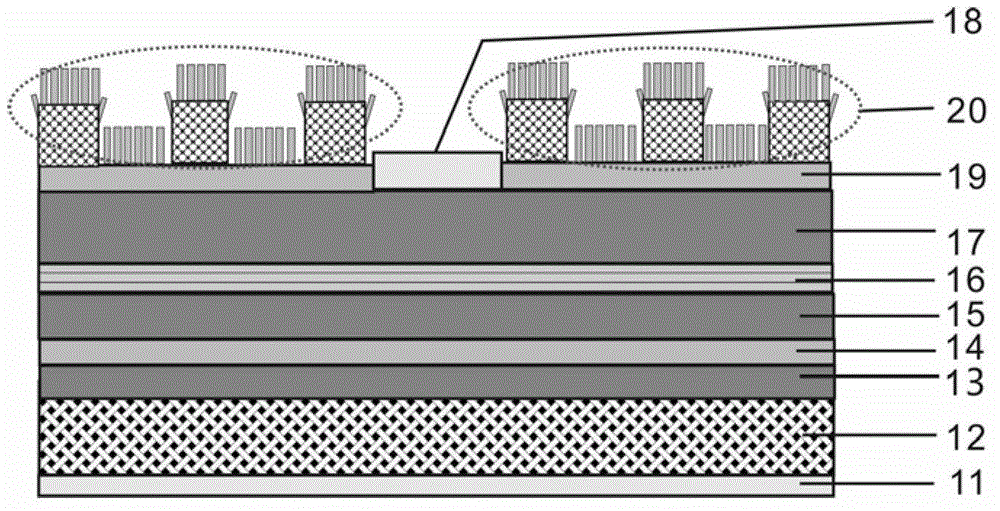

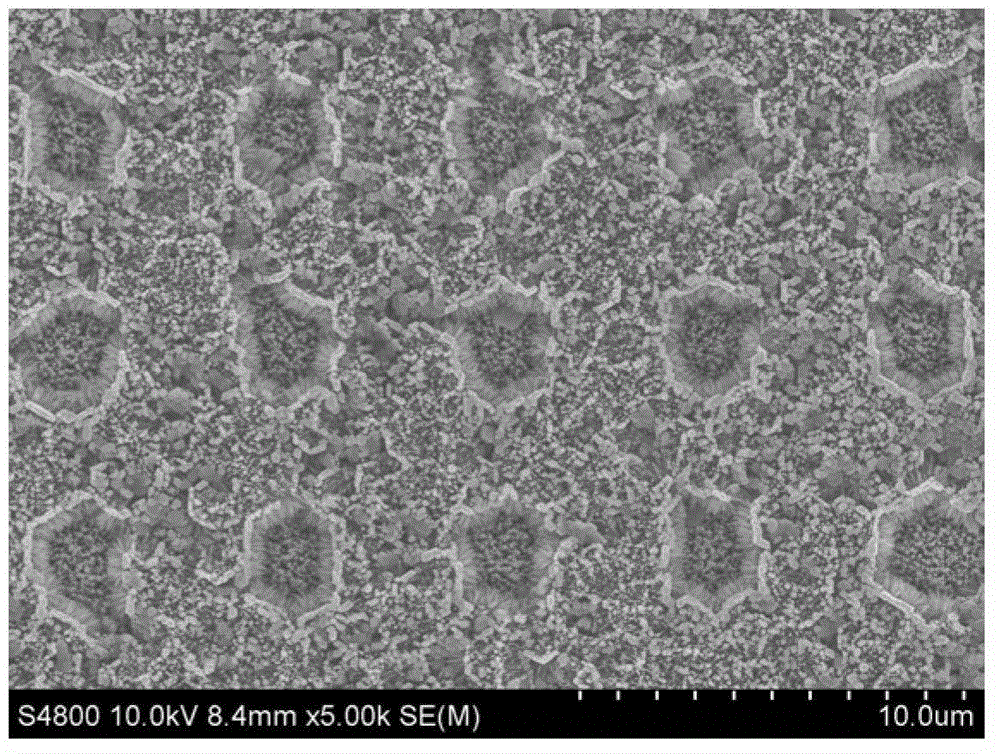

[0026] LED tube core with ZnO micro pattern array of the present invention, as figure 1 or figure 2 As shown, its structure is on the light-emitting surface of the LED die ( figure 1 The current spreading layer 6 of the same-plane electrode GaN-based LED die shown, figure 2 The n-type GaN layer 17) of the laser lift-off vertical structure GaN-based LED tube core is sputtered with a ZnO seed layer 7, a ZnO micro-pattern array is grown on the ZnO seed layer 7, and nanorods are grown on the ZnO micro-pattern array, A ZnO micron periodic pattern and nanorod composite structure 10 are formed. the following to figure 1 The same-plane electrode GaN-based LED is shown as an example to illustrate the growth process of an LED die with a ZnO micron periodic pattern and a nanorod composite structure 10, which specifically includes the following steps:

[0027] (1) if figure 1As shown, a complete epitaxial wafer structure is epitaxially grown on a substrate 1 by metal-organic chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com