Cage type rotor permanent magnetic synchro motor starting device and control method

A permanent magnet synchronous motor, squirrel-cage rotor technology, applied in starting devices, single motor speed/torque control, etc., can solve the problems of long starting time, reduced starting torque, and high cost, and achieve high reliability and reduced Torque ripple, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

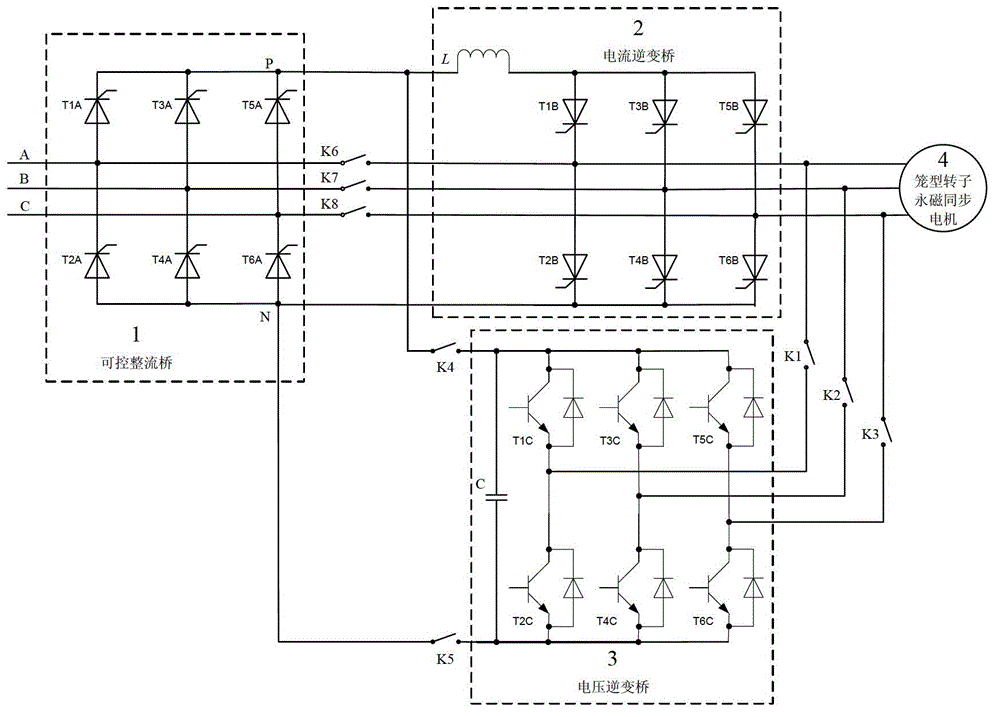

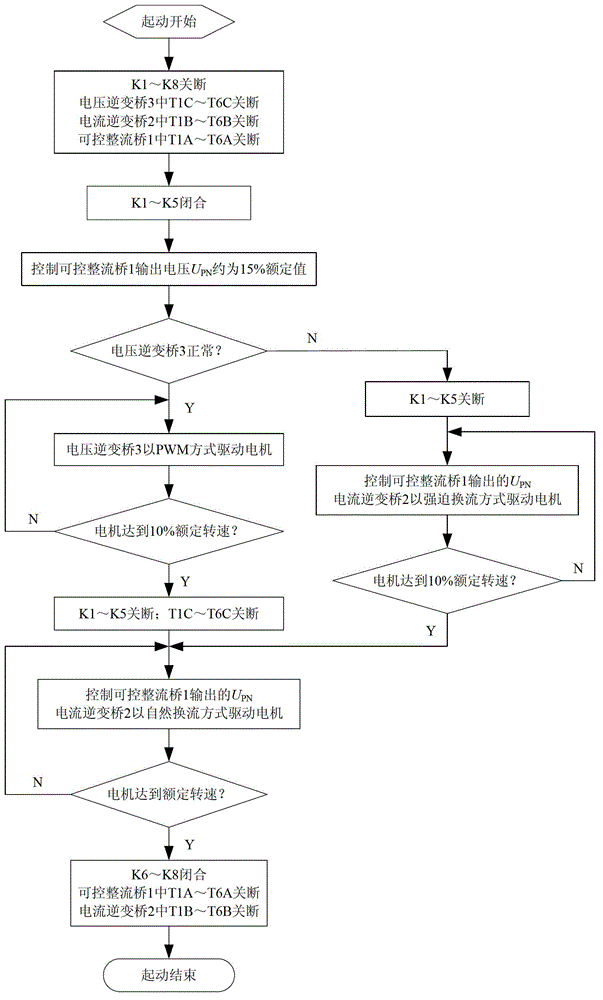

[0032] Combine below figure 1 , figure 2 The present invention is described further:

[0033] like figure 1 As shown, the present invention mainly includes a controllable rectifier bridge 1, a current inverter bridge 2, a voltage inverter bridge 3, a cage rotor permanent magnet synchronous motor 4 and switches K1-K8.

[0034] The input end of the controllable rectifier bridge 1 is connected to three-phase AC power sources A, B, and C. The input end of the current inverter bridge 2 is connected to the output end of the controllable rectifier bridge 1 , and its output end is connected to the input end of the cage rotor permanent magnet synchronous motor 4 . The input terminal of the voltage inverter bridge 3 is connected with the input terminal of the current inverter bridge 2 and the output terminal of the controllable rectifier bridge 1 through the switches K4 and K5, and its output terminal is connected with the current inverter bridge 2 through the switches K1, K2 and K3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com