Composite material plate with folding sandwich structure and forming method thereof

A composite material board and composite material technology, applied in the field of composite material board with folded sandwich structure and its forming, can solve the problems of reduced structural load-bearing efficiency, large environmental pollution, high process cost and resource cost, and achieve safety The effect of lowering, adjustable three-dimensional stiffness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

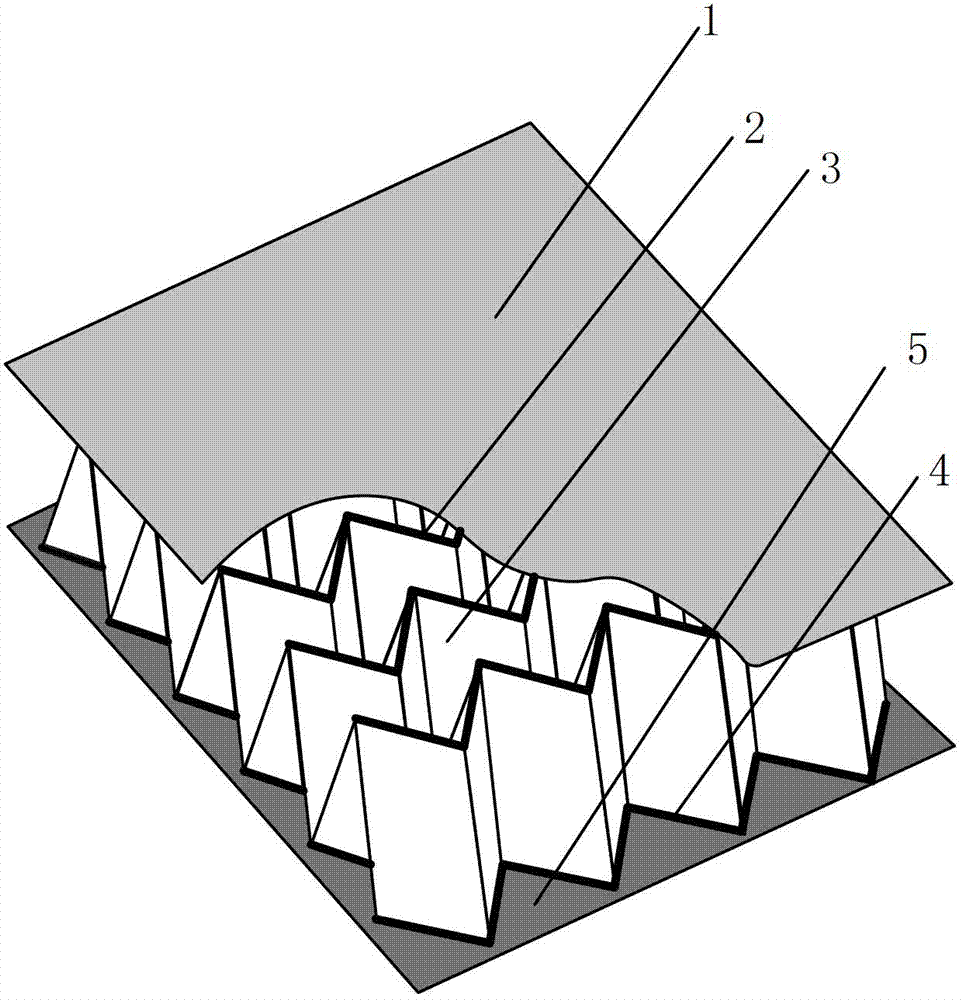

[0030] The composite material plate was prepared by co-curing with CF3031 / 5228A carbon fiber fabric folded sandwich core, and the specific steps are as follows:

[0031] (1) Prepare the upper and lower panels of CF3031 / 5228A: pre-cure the laminate of CF3031 / 5228A at 130°C / 1h, the thickness of the upper and lower panels is 2.1mm, and the curing degree is less than 0.2;

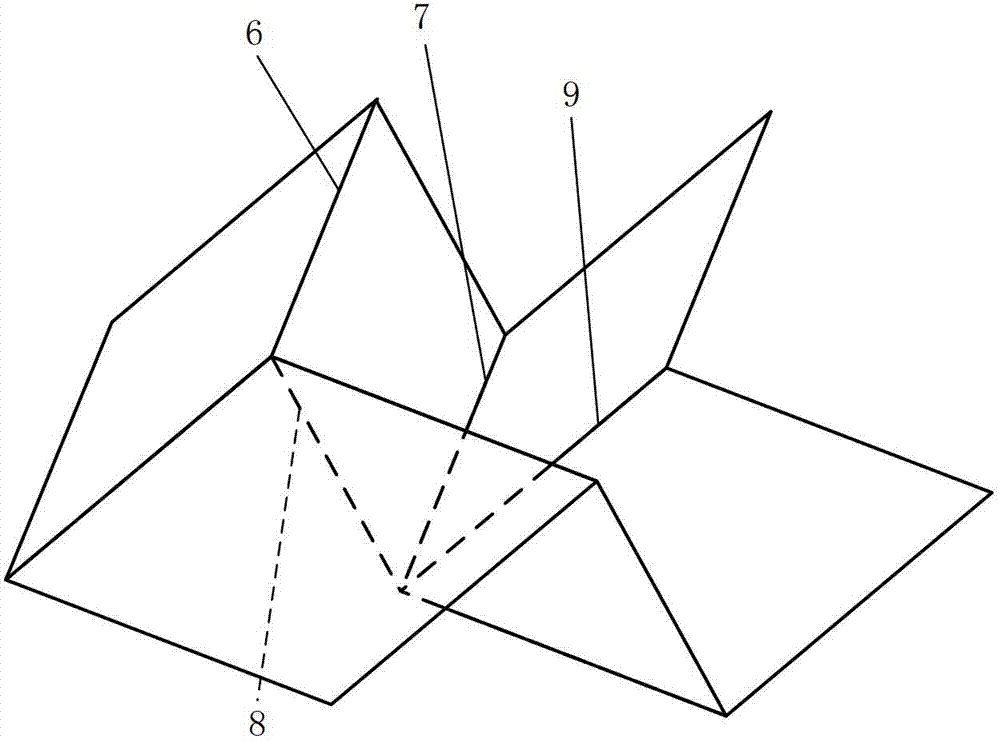

[0032] (2) Prepare the CF3031 / 5228A folded sandwich. The preparation of the folded sandwich is to make a prepreg fabric composed of fiber fabric and thermosetting resin. According to the warp and weft cell sizes of the prepreg fabric, manually press the oblique Lower crease 6, oblique upward crease 7, warp upward crease 8 and warp downward crease 9. Apply pressure in the warp and weft directions of the fabric, so that the fabric is folded upward along the upper crease and folded downward along the lower crease to form a folded body; pre-cure the folded CF3031 / 5228A carbon fiber fabric core at 130°C / 1h, The cur...

Embodiment 2

[0036] The U-shaped front edge of the composite material was prepared by co-curing with the CF3031 / 5228A carbon fiber fabric folded sandwich core. The specific steps are as follows:

[0037](1) Prepare CF3031 / 5228A upper skin and lower skin: Lay CF3031 / 5228A upper skin and lower skin in the mold respectively, pre-cure the laminated CF3031 / 5228A at 130°C / 1h, The thickness of the upper and lower skins is 2.0mm, and the curing degree is less than 0.2;

[0038] (2) Prepare the CF3031 / 5228A folded sandwich. The preparation of the folded sandwich is to make a prepreg fabric composed of fiber fabric and thermosetting resin. According to the warp and weft cell sizes of the prepreg fabric, manually press the oblique Lower crease 6, oblique upward crease 7, warp upward crease 8 and warp downward crease 9. Apply pressure in the warp and weft directions of the fabric, so that the fabric is folded upward along the upper crease and folded downward along the lower crease to form a folded bo...

Embodiment 3

[0042] Composite slabs were prepared by co-bonding CF3031 / 5228A carbon fiber fabric folded sandwich cores.

[0043] The difference between this embodiment and embodiment 2 is that the SY-14 adhesive film is replaced by 50g / m at the position where the folded core contacts the upper and lower panels 2 The amount of 5228A glue is brushed, and the glue film is removed during assembly. The rest is the same as in Example 2, and a composite material plate prepared by co-bonding CF3031 / 5228A carbon fiber fabric folded sandwich core can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com