High-cutting-force diamond micro powder and preparation method thereof

A technology of diamond micropowder and high cutting force, applied in diamond and other directions, can solve the problems of large cutting edge of a single particle, small number of cutting edges, fragmentation of cleavage surface, etc., to achieve less scratches on the surface of the workpiece, long service life, raw materials sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

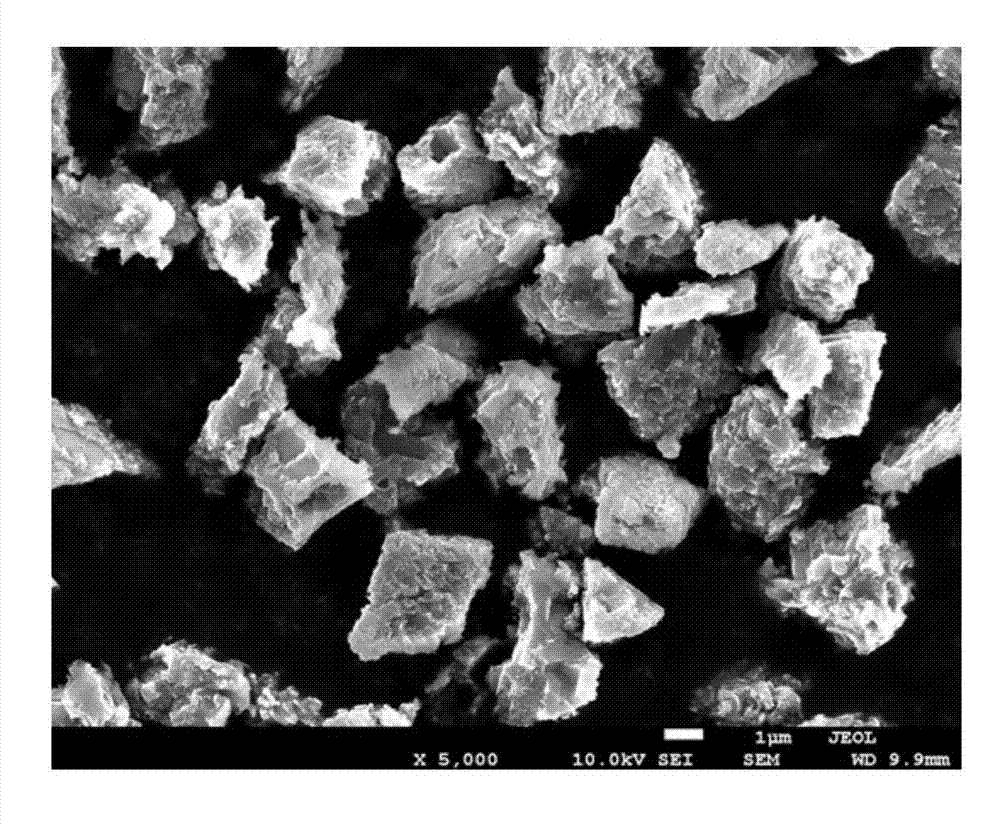

[0042]The product of the present invention is 3 μm high-cutting force diamond powder, and the particle surface of the product has a large number of sharp cutting edges, and its cutting force reaches about 2.3 times that of ordinary single crystal diamond powder; its specific surface area is 1.415m 2 / g, compared with the specific surface area of ordinary single crystal diamond powder (1.259 m 2 / g), the specific surface area increased by 12.39%.

[0043] The preparation method of the product 3 μm high cutting force diamond micropowder of the present invention:

[0044] Weigh 500 g of single crystal diamond powder with an average particle size of 3.4 microns and put it into a porcelain crucible, put it into a vacuum furnace together with the porcelain crucible, and slowly evacuate until the vacuum degree reaches 10 -2 Pa; then heated to 650°C, and filled with a mixed gas of nitrogen and oxygen at the same time, the volume ratio of nitrogen and oxygen in the mixed gas was con...

Embodiment 2

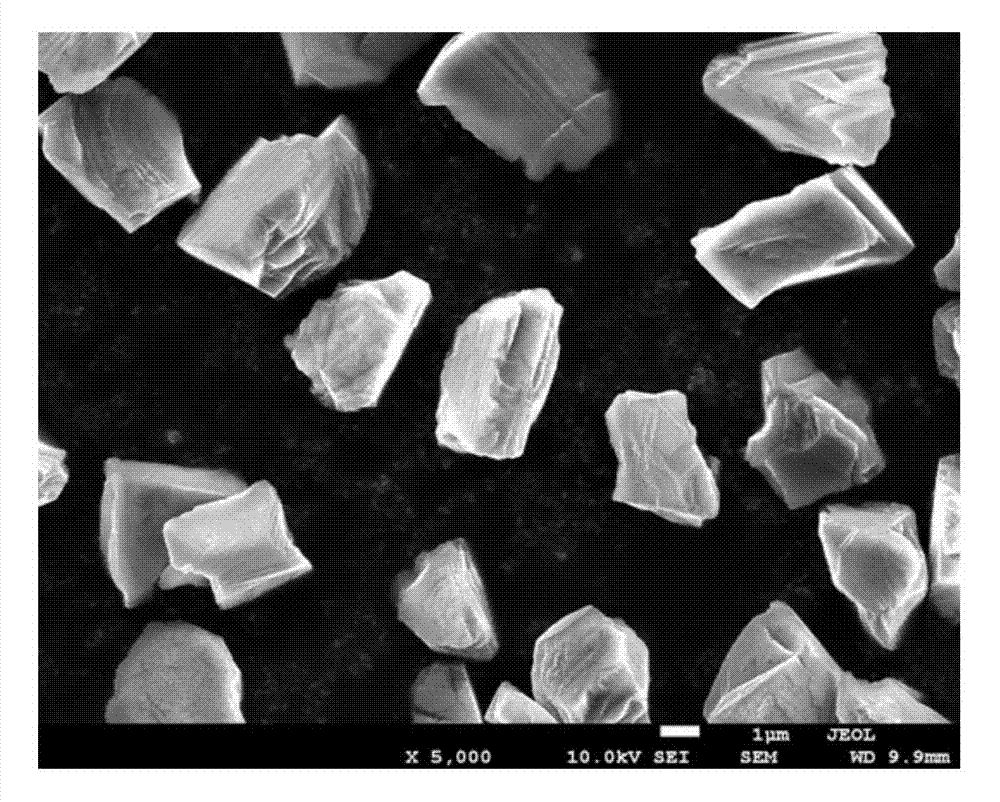

[0049] The product of the present invention is 6 μm high-cutting force diamond powder. The particle surface of the product has a large number of sharp cutting edges, and its cutting force is about 3.3 times that of ordinary single crystal diamond powder; its specific surface area is 0.654m 2 / g.

[0050] Compared with the specific surface area of ordinary 6μm single crystal diamond powder (0.448m 2 / g), the specific surface area increased by 45.98%.

[0051] The preparation method of the product 6 μm high cutting force diamond micropowder of the present invention:

[0052] Weigh 500 g of single crystal diamond powder with an average particle size of 6.5 microns and put it into a porcelain crucible, put it into a vacuum furnace together with the porcelain crucible, and slowly evacuate until the vacuum degree reaches 10 -2 Pa; then heated to 700°C, and filled with a mixed gas of nitrogen and oxygen at the same time, the volume ratio of nitrogen and oxygen in the mixed gas wa...

Embodiment 3

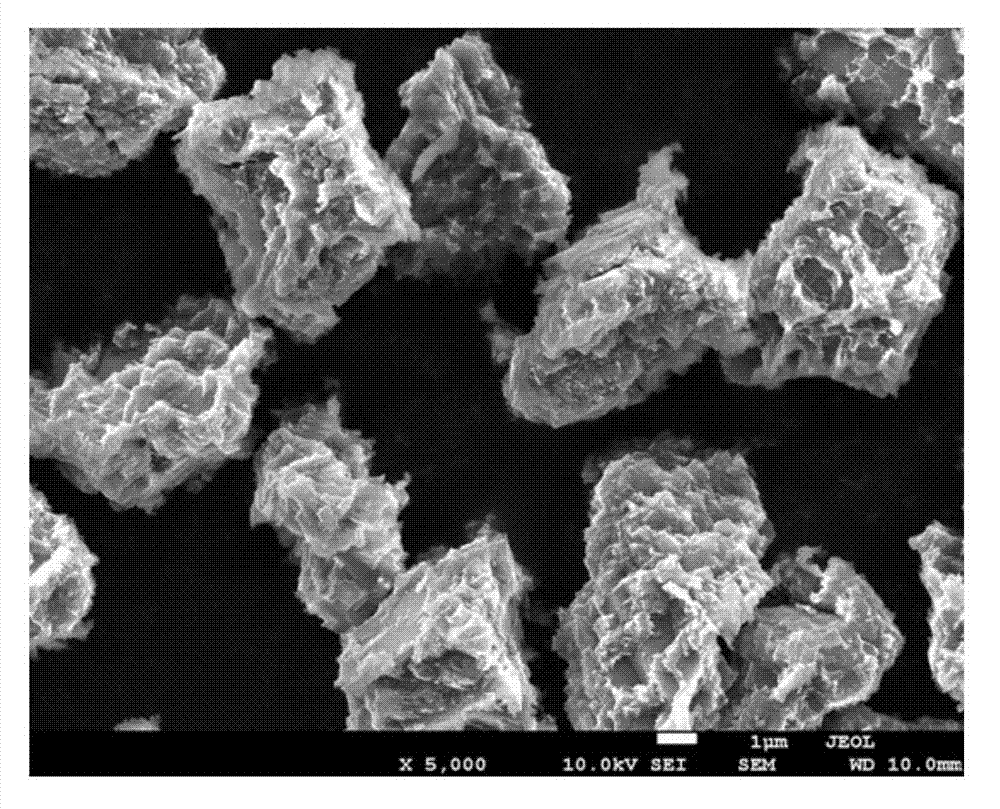

[0057] The product of the present invention is 9 μm high cutting force diamond powder, the particle surface of the product has a large number of sharp cutting edges, and its cutting force is about 2.8 times that of ordinary single crystal diamond powder; its specific surface area is 0.416m 2 / g.

[0058] Compared with the specific surface area of ordinary 9μm single crystal diamond powder (0.352m 2 / g), the specific surface area increased by 18.18%.

[0059] The preparation method of the product 9 μm high cutting force diamond micropowder of the present invention:

[0060] Weigh 500 g of single crystal diamond powder with an average particle size of 9.4 microns and put it into a porcelain crucible, put it into a vacuum furnace together with the porcelain crucible, and slowly evacuate until the vacuum degree reaches 10 -2 Pa; then heated to 700°C, and filled with a mixed gas of nitrogen and oxygen at the same time, the volume ratio of nitrogen and oxygen in the mixed gas wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com