Method and device for online measurement of gas-phase flow rate of gas-liquid two-phase flow based on single throttling element

A gas-liquid two-phase flow, throttling element technology, applied in the field of multi-phase flow measurement, can solve the problems of high price, difficult to guarantee the ratio consistency, restricting popularization and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

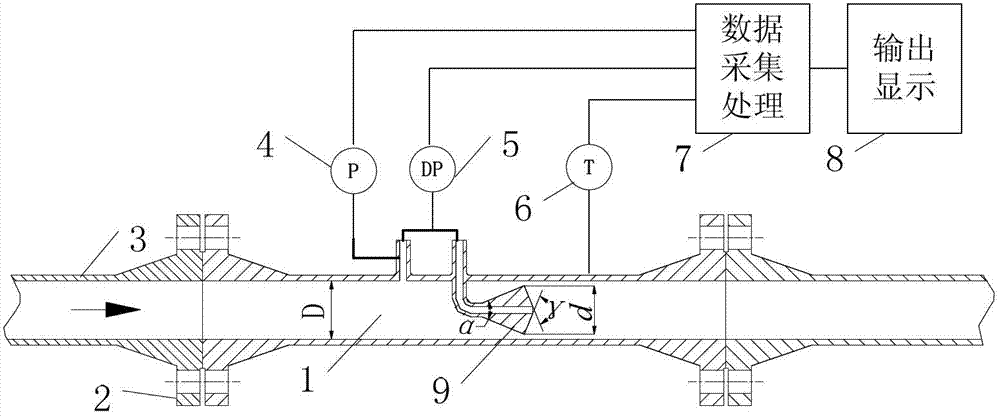

[0017] The method for measuring the gas-phase flow rate of the single differential pressure gas-liquid two-phase flow of the present invention will be further described in conjunction with the accompanying drawings and by taking the V inner cone throttling element as an example.

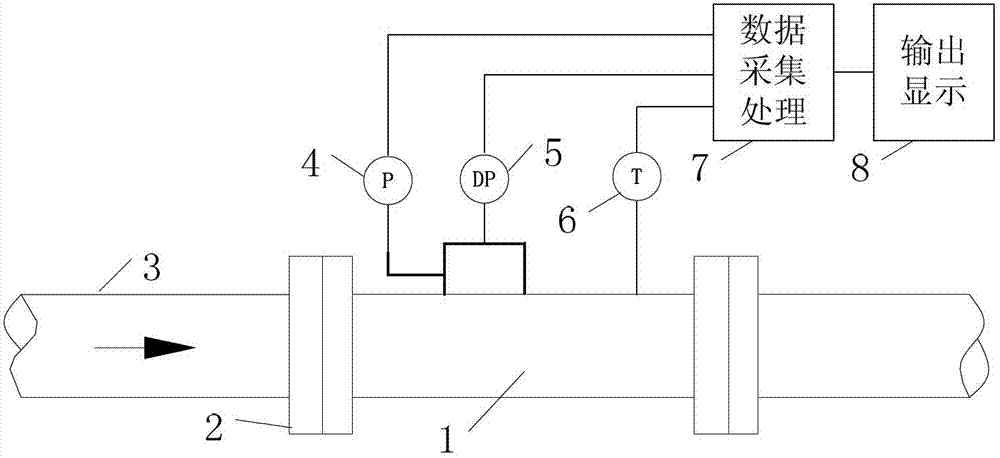

[0018] see figure 1 , a general embodiment of the invention. The differential pressure flowmeter 1 is installed on the measuring pipeline 3 through the flange 2 (or other connection methods), the pressure transmitter 4 measures the pressure of the gas-liquid two-phase flow flowing through the differential pressure flowmeter 1, and the differential pressure transmitter 5 The differential pressure of the differential pressure flowmeter 1 is detected, and a temperature transmitter 6 is installed downstream of the flowmeter to obtain the temperature of the gas-liquid two-phase flow. The pressure, temperature and differential pressure measured by the above-mentioned pressure transmitter, temperature tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com