A hydrogen or oxygen electrochemical pumping catalytic membrane reactor and its applications

A catalytic membrane reactor and electrochemical technology, applied in the field of converting benzene to aniline, can solve the problems of low maximum conversion rate and difficult catalyst regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

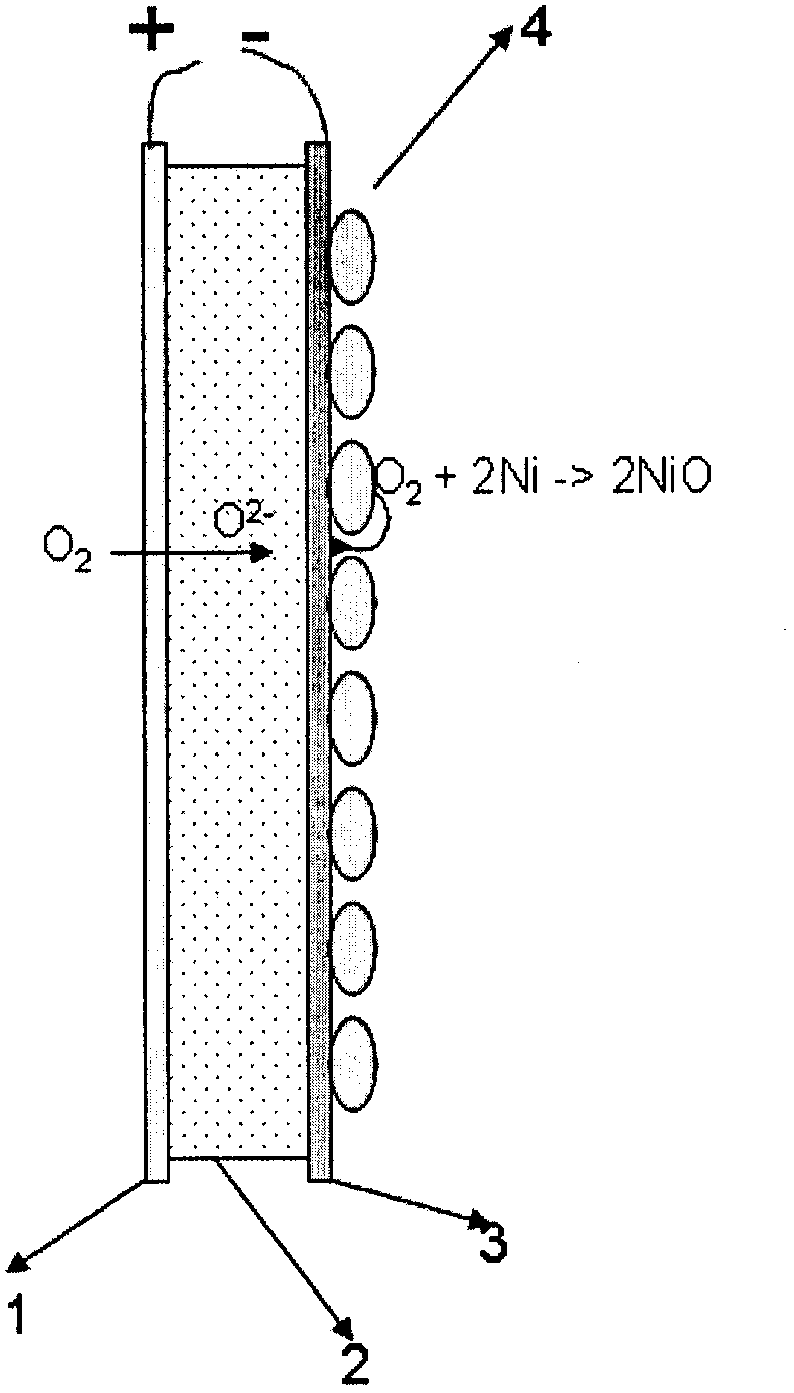

[0085] Catalytic reactor with membrane equipped with a device for electrochemical oxygen pumping consisting of a composite catalytic membrane in which the catalyst for the direct amination reaction of benzene is a bimetallic with nickel / nickel oxide and platinum nanoparticles Catalyst; the electrocatalyst in the permeate side is a catalyst with platinum nanoparticles; the porous anode (3) consists, for example, of nickel and zirconium oxide cermet (YSZ) stabilized with yttrium oxide; the cathode (1), for example, of lanthanum strontium manganite (LSM); the electrolyte (2) is yttrium-doped zirconium phosphate.

Embodiment 2

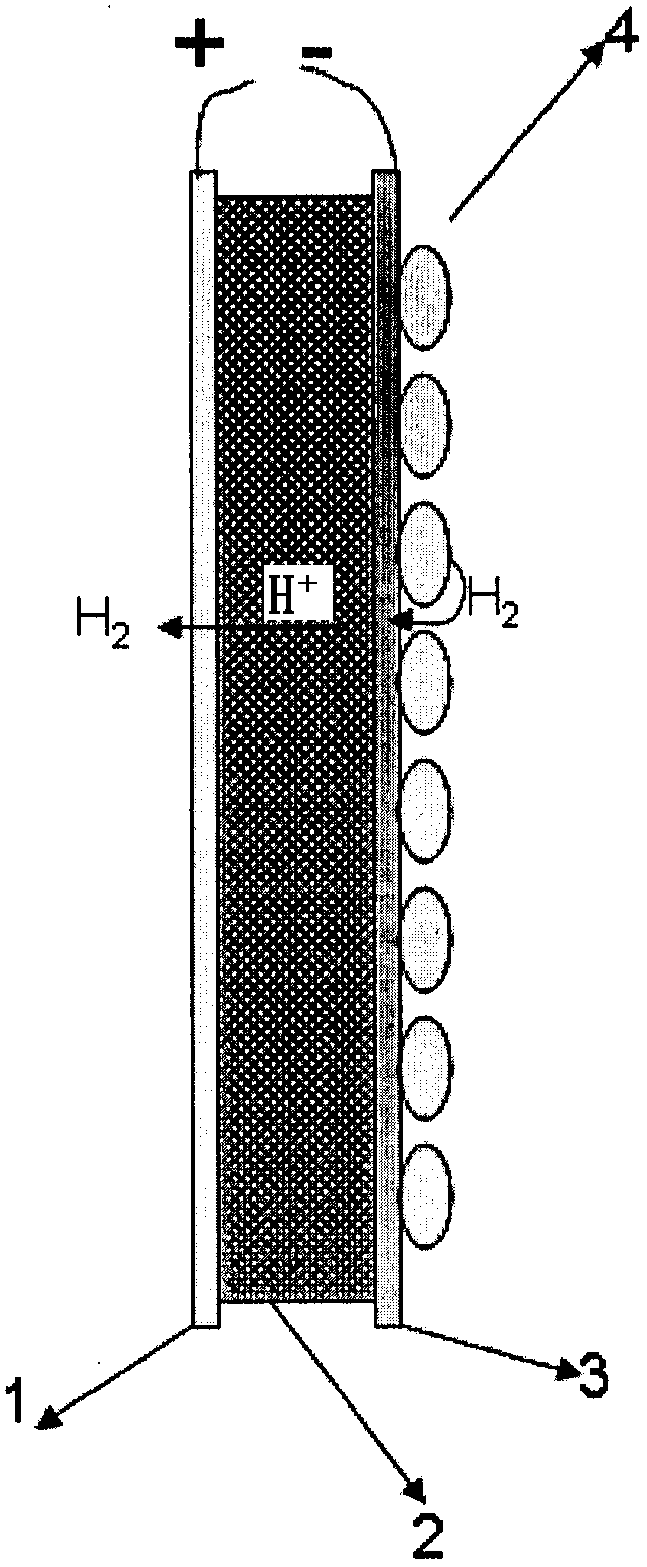

[0087] Electrocatalytic pumping catalytic membrane reactor in which hydrogen can be removed from the surface of the chemical catalyst by electrochemical pumping of hydrogen, which includes a nickel / nickel oxide chemical catalyst to provide direct amination of benzene to aniline, the chemical catalyst is used The platinum nanoparticles are modified, which in turn provide for the electro-oxidation of hydrogen. The composite catalyst should be deposited in the interface between the anode (3) and the electrolyte (2); the anode (3) consists of a porous palladium film about 1 μm thick; the electrolyte (2) consists of yttrium-doped zirconium phosphate; the cathode ( 1) Constructed of a 0.5 μm thick porous palladium membrane. In the electrolyte (2) / cathode interface the platinum electrocatalyst should be deposited as nanoparticles. This is used to provide hydrogen reduction or reaction of hydrogen with oxygen.

Embodiment 3

[0089] An electrocatalytic pumping catalytic membrane reactor in which oxygen is electrochemically pumped onto the surface of a chemical catalyst that includes a nickel / nickel oxide chemical catalyst to provide direct amination of benzene and electrooxidation of oxygen. The composite membrane consists of a porous YSZ anode (3) impregnated with the nickel / nickel oxide catalyst, an impregnable YSZ electrolyte (2) layer, and a lanthanum strontium manganite (LSM) cathode (1) layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com