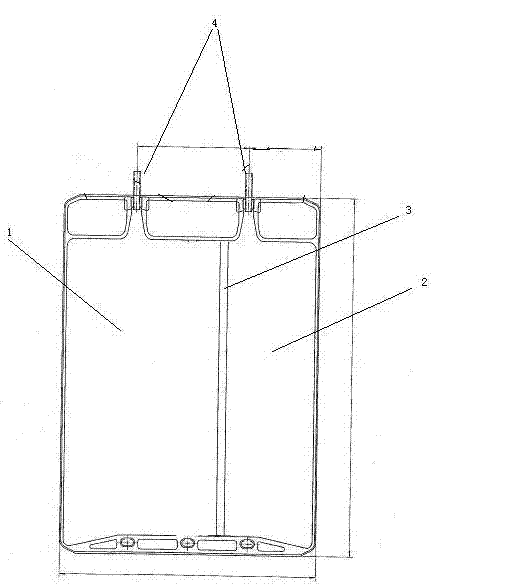

Novel double-chamber transfusion bag for packing parenteral nutritional injection

A parenteral nutrition and infusion bag technology, applied in the field of medicine, can solve problems such as lack of mixing conditions, increased pollution, and inability to completely ensure that the liquid medicine is not polluted, and achieve the effect of reducing pollution risks and increasing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

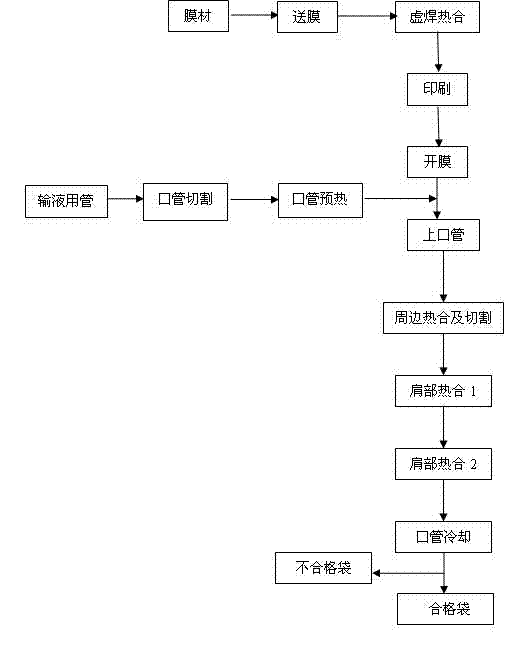

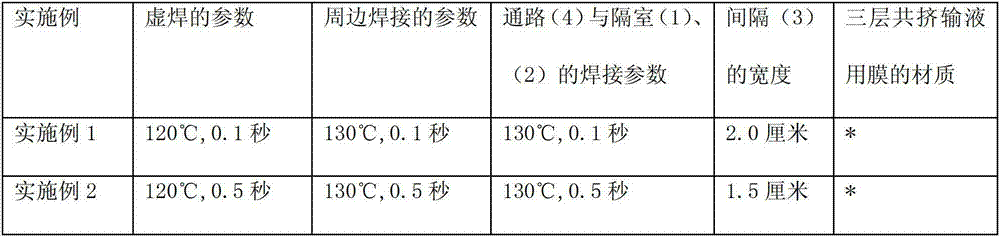

[0031] The preparation technology of double-chamber transfusion bag of the present invention

[0032]

[0033]

[0034]

[0035]*: In the three-layer co-extrusion film for infusion, the outer layer film is composed of polypropylene, styrene-ethylene-butylene copolymer; the middle layer film is composed of polypropylene / polyethylene, styrene-ethylene-butylene copolymer; The layer film is composed of polypropylene, styrene-ethylene-butylene copolymer.

[0036] **: The three-layer co-extrusion film for infusion is derived from the special film of PolyCine GmbH (registration number: Jinyaobaozi J20060015).

experiment example 1

[0037] Experimental Example 1 - Appearance Inspection

[0038] Take 10 each of Examples 1-32 of the present invention, respectively, and visually observe them in a bright place with natural light, all of which are transparent, smooth, and free of foreign matter visible to the naked eye. There are no cracks, fissures, pores, colored inclusions and foreign matter deposits at the mouth tube interface.

experiment example 2

[0039] Experimental Example 2 - Identification

[0040] (1) Microscopic characteristics: 10 samples of each of Examples 1-32 of the present invention were taken, cut into appropriate thicknesses, and observed under a microscope. The cross-section showed clear three layers.

[0041] (2) Actual welding strength: Take the examples 1-32 of the present invention and measure them respectively according to the method of composite bag in the heat sealing strength measurement method (YBB00122003). The average value of each heat sealing part is not less than 25N / 15mm.

[0042] (3) Insufficient weld strength: Take Examples 1-32 of the present invention and measure them according to the composite bag method in the heat seal strength measurement method (YBB00122003), and the average value of each heat seal part is (5N-20N) / 15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com