Composite sedimentation tank

A composite sedimentation and tank body technology, applied in the field of composite sedimentation tanks, can solve the problems of low efficiency of effective volume use and large floor area of sedimentation tanks, and achieve improved volume utilization and sedimentation effects, high land utilization, and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

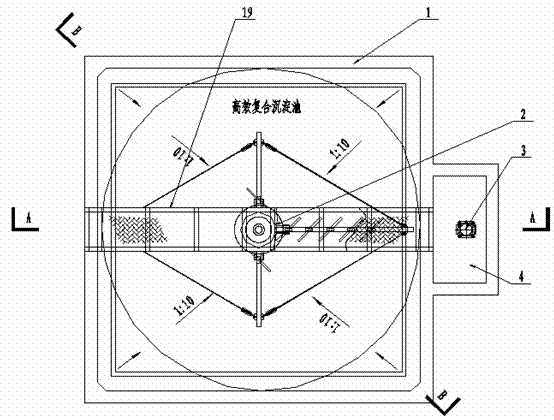

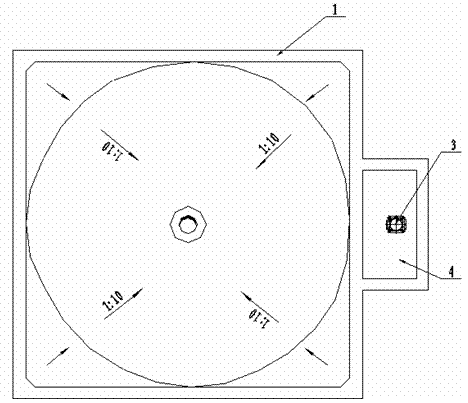

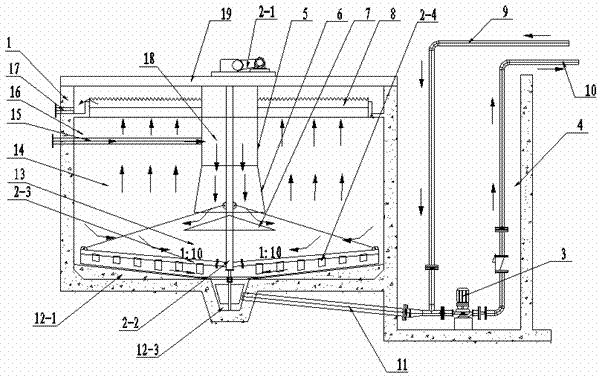

[0027] In part of the sewage treatment unit of the first-stage project of a sewage treatment plant, the sedimentation tank adopts a circular sedimentation tank with a diameter of φ9.0×4.5m, and the preliminary pretreatment facilities are three continuous reaction tanks of 2.0×2.0m×3.0m. The subsequent sewage treatment is a 9.0×2.0m×4.5m filter and disinfection tank (see the layout drawing of part of the sewage treatment unit in the first phase of the project) Figure 5 ).

[0028] In this part of the sewage treatment unit after the expansion of the second phase of the sewage treatment plant, the sedimentation tank is now implemented in the form of a square tank body and a circular truncated inverted cone bottom structure, with a diameter of 9.0×4.5m, and the sedimentation tank The area is increased by more than 25%, which further improves the volume utilization rate of the sedimentation tank and strengthens the sedimentation effect; the initial pretreatment facility is still three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com