Device and method for producing hollow fiber membranes

A production device and fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of uniformity, poor stability, uneven membrane wall thickness, and can not effectively solve the problem of uneven membrane wall thickness. , to achieve the effect of simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

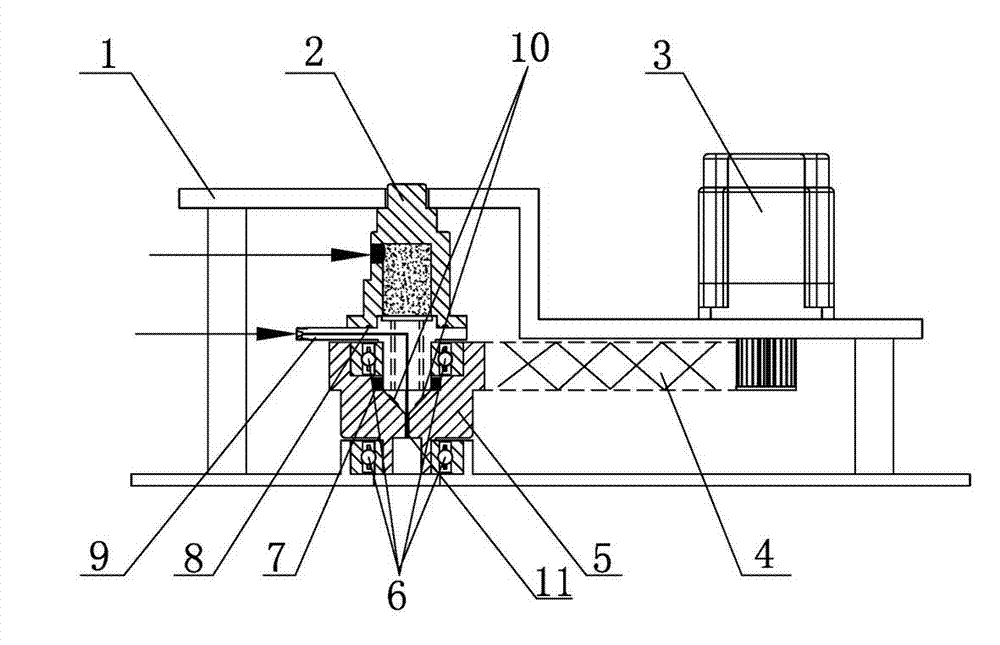

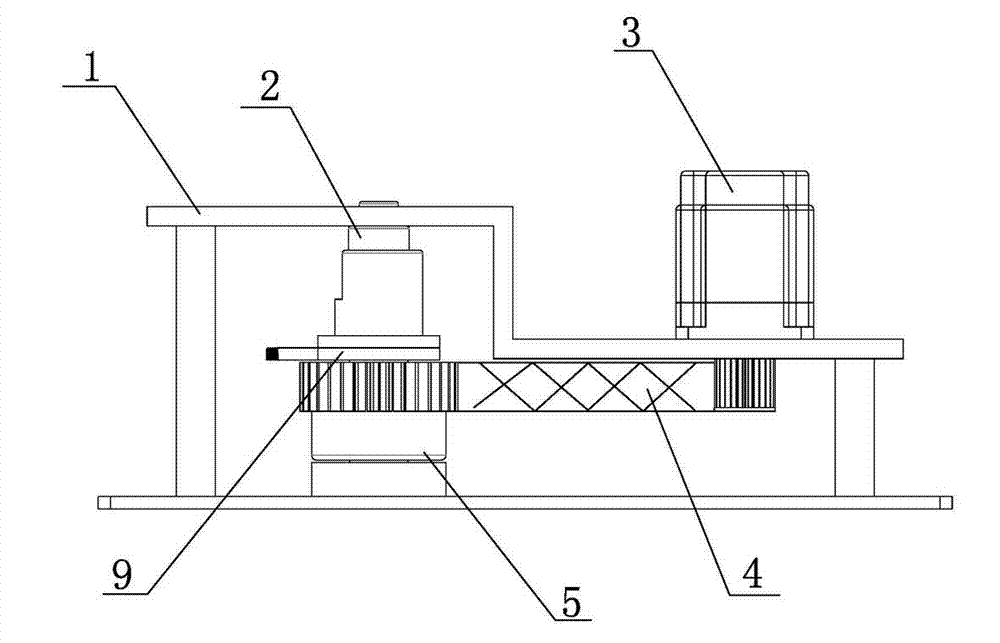

Method used

Image

Examples

Embodiment 1

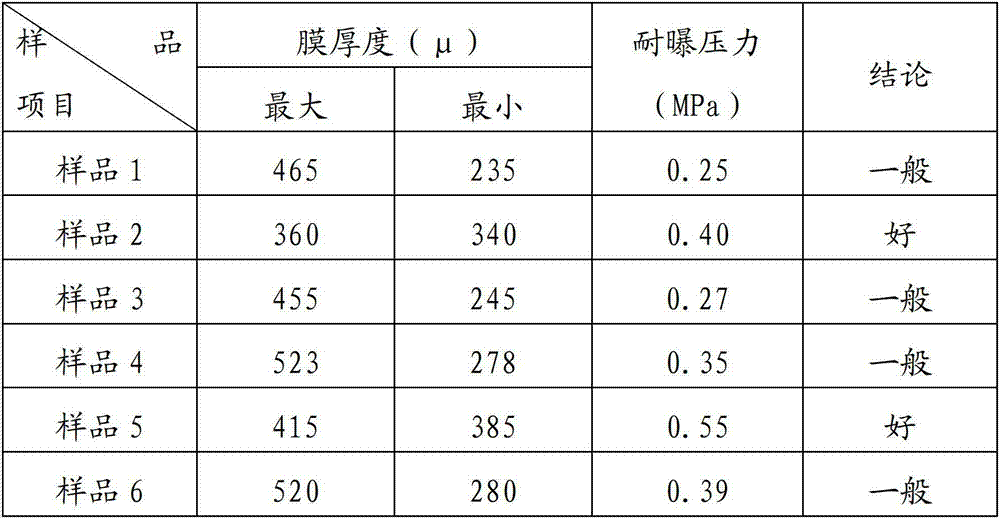

[0026] The hollow fiber membrane production device of the present invention is used to produce PVDF hollow fiber membranes by immersion precipitation phase inversion method, and the production spinning traction speed is set to be 12 m / min. First, the spinneret does not rotate, which is equivalent to general spinning Take sample 1 after spinning production is stable for 10 minutes; then turn on the rotary switch of the rotary spinneret, set the rotating speed to 50 rpm, take sample 2 after spinning production is stable for 10 minutes; change back to the original ordinary spinning head , Take sample 3 after spinning production stabilizes for 10 minutes; After post-processing the 3 samples according to the usual production method, the detection data and analysis are shown in the following table.

Embodiment 2

[0028] The hollow fiber membrane production device described in the present invention is used for the production of PVDF hollow fiber membrane by thermal phase separation method, and the production spinning drawing speed is set to be 15 / min. First, the spinneret does not rotate, which is equivalent to a general spinneret. , take sample 4 after the spinning production is stable for 10 minutes; then turn on the rotary switch of the rotary spinneret, set the rotating speed as 65 rpm, and take sample 5 after the spinning production is stable for 10 minutes; change back to the original common spinning head, Take sample 6 after the spinning production is stable for 10 minutes; after post-processing the 3 samples according to the usual production method, the test data and analysis are shown in Table 1.

[0029] The performance measurement method of the hollow fiber membrane of the present invention is: measure the wall thickness of the hollow fiber membrane with a JXB-C computer readi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com