Multifunctional foam cutting machine

A cutting machine, multi-functional technology, applied in metal processing and other directions, can solve the problems of unsuitable production and application of small enterprises, low manual cutting efficiency, poor surface roughness, etc., to facilitate promotion and use, and save calculation and operation time. , Improve the effect of surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

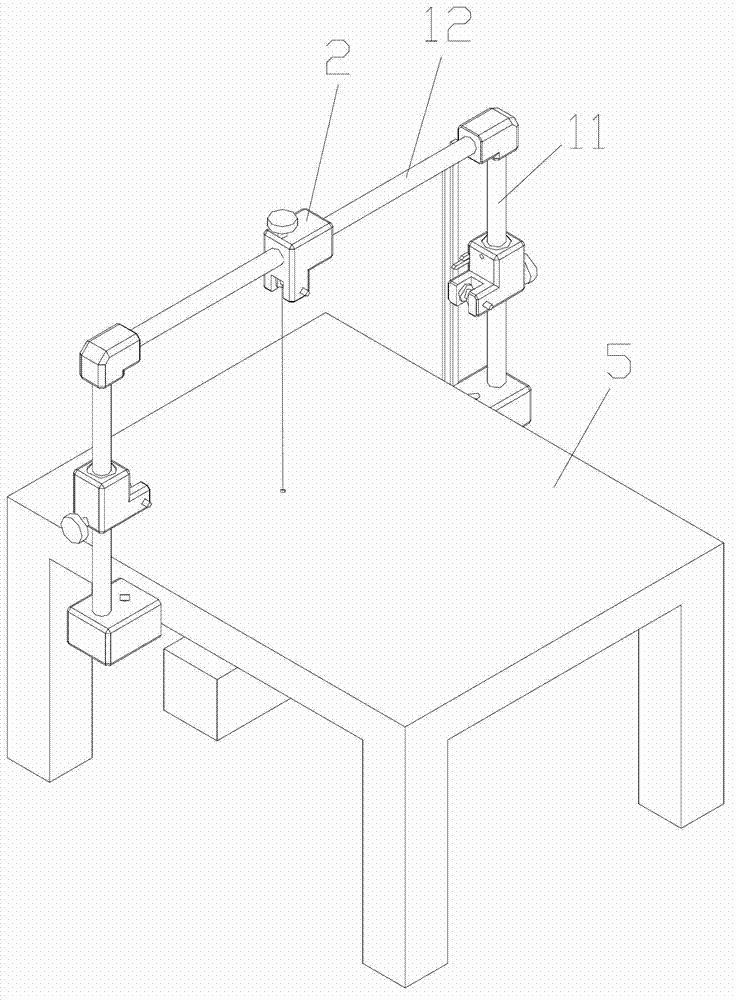

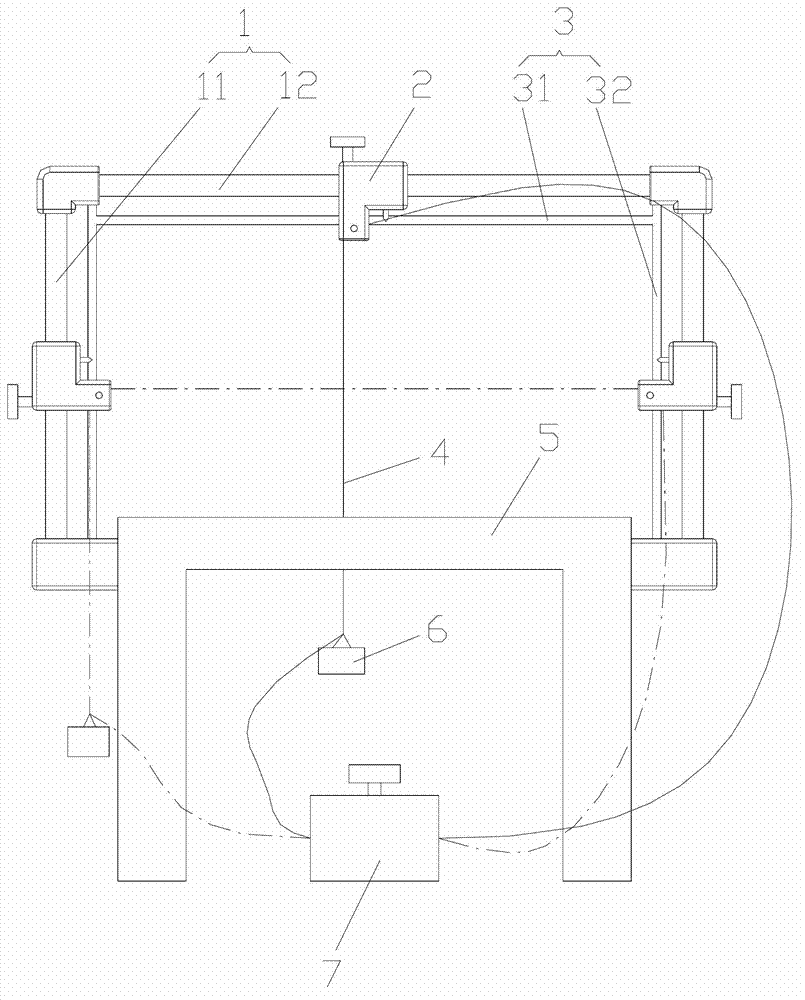

Image

Examples

Embodiment

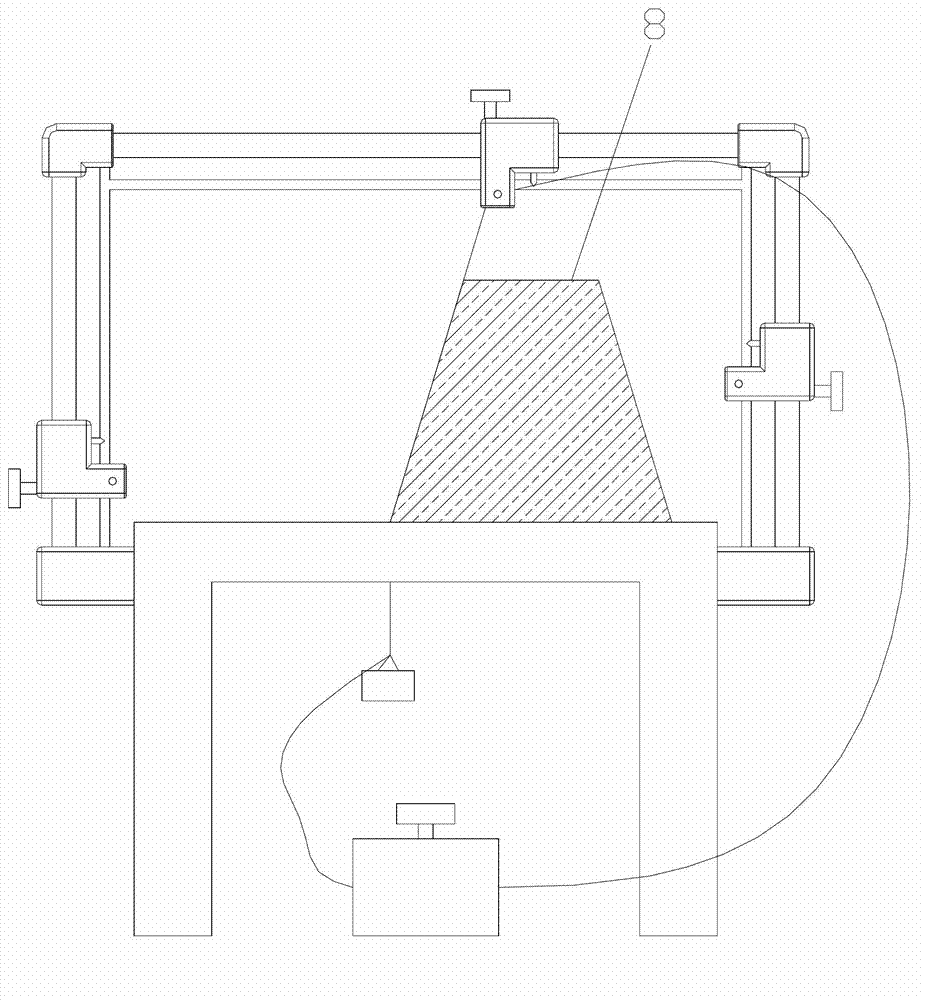

[0018] There is a foam shape that needs to be cut into an isosceles trapezoid. Now use the vertical wire of this cutting machine to cut it. The steps are as follows:

[0019] a. Assemble the device to a ready-to-use state, and connect to the power supply;

[0020] b. Cut into square materials according to the maximum size of pattern 8;

[0021] c. Calculate the angle between the hypotenuse and the horizontal plane;

[0022] d. Adjust the vertical adjustment mechanism 2 so that its pointer points to the angle value calculated in the previous step;

[0023] e. Turn on the power supply and adjust the power regulator 7 to the required voltage position;

[0024] f. When the heating wire 4 is heated and can be cut, align the lower end of the pattern 8 with the lower end of the heating wire 4, and move the pattern 8 at a constant speed. At this time, the cutting of a hypotenuse of the isosceles trapezoid is completed;

[0025] g. According to the previous step, cut the slope on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap