Aqueous synthetic leather production line

A synthetic leather and production line technology, applied in the field of artificial leather production and water-based artificial leather production, can solve problems such as the lack of industrial production of water-based synthetic leather, and achieve the effect of reducing capital construction and equipment investment, reducing floor space and simple structure layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

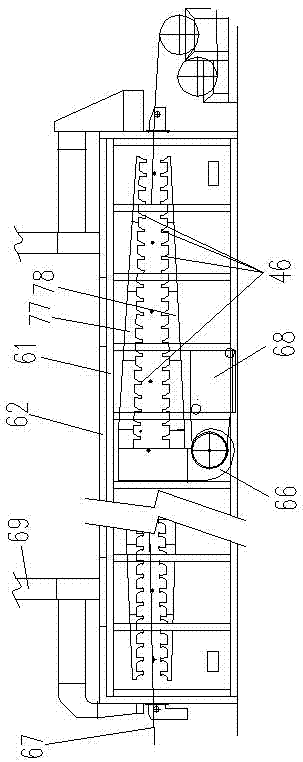

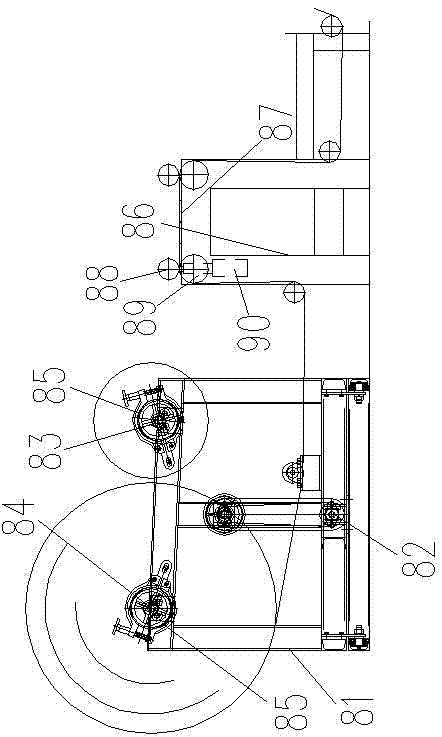

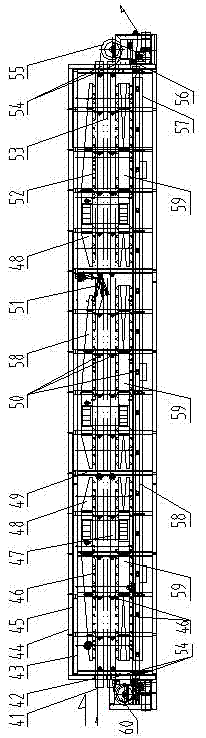

[0028] Such as figure 1 As shown, the water-based synthetic leather production line of the present invention includes a double-station release paper unwinding machine 1, a release paper splicing table 2, a storage device 3, the first (surface layer) precision coating machine 4, the first A drying oven 5, two-roll cooling machine 6, the second (foaming) precision coating machine 7, the first multi-layer return (foaming) oven 8, four-roll cooling machine 9, the third (bonding layer) precision coating machine Coating machine 10, second drying oven 11, automatic laminating and laying device 12, laminating machine 13, second multi-layer folding oven 14, multi-roll cooling machine 15, stripping device 18, trimming machine 17 and duplex The double-station coiler includes a product winding part 16A and a release paper winding part 16B.

[0029]Among them, the storage device 3 adopts the leather storage device of the artificial leather four-roll calendering equipment disclosed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com