Nonlinear inductor loss measuring method based on direct current bias

A technology of DC bias and inductance loss, which is applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., and can solve problems such as different losses, long solution process, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below with reference to accompanying drawing:

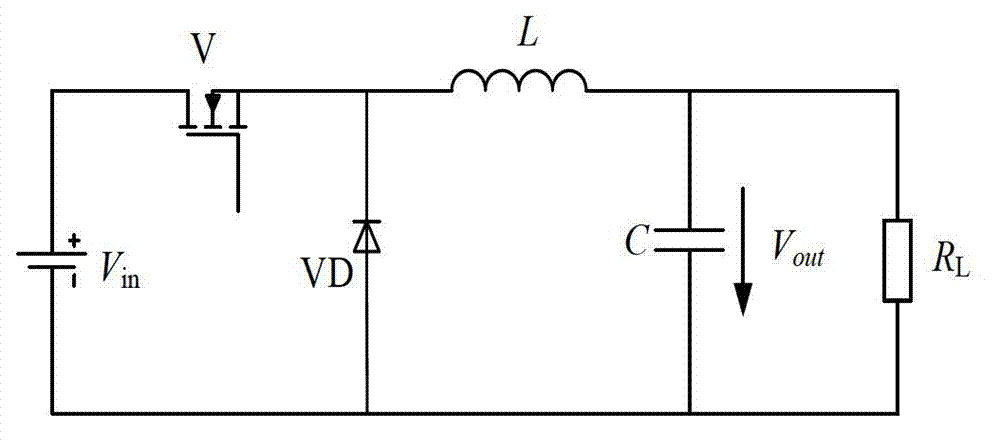

[0061] In this embodiment, the loss of the inductance in the Buck circuit is measured, and the Buck circuit is as figure 1 As shown, the input voltage of the circuit is V in =5V, the output voltage is V out =1.3V, the working frequency is f=8MHz, the average current after the circuit enters the steady state is I dc =13A.

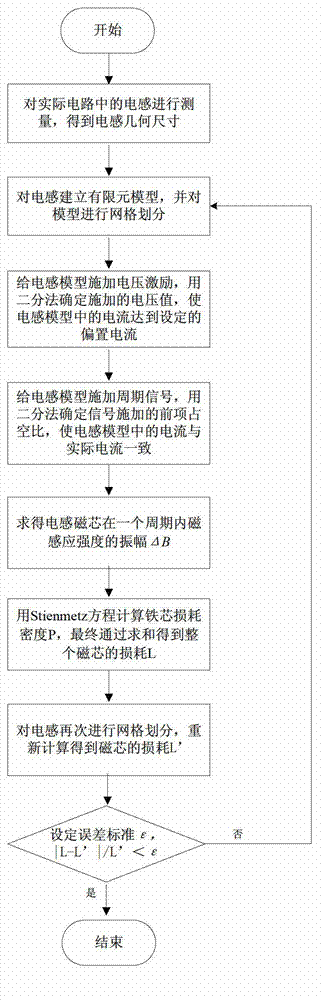

[0062] refer to image 3 , the present invention is as follows to the loss test procedure of inductance in Buck circuit:

[0063] Step 1, use a micrometer to measure the size of the measured inductance to obtain the geometric parameters of the inductance.

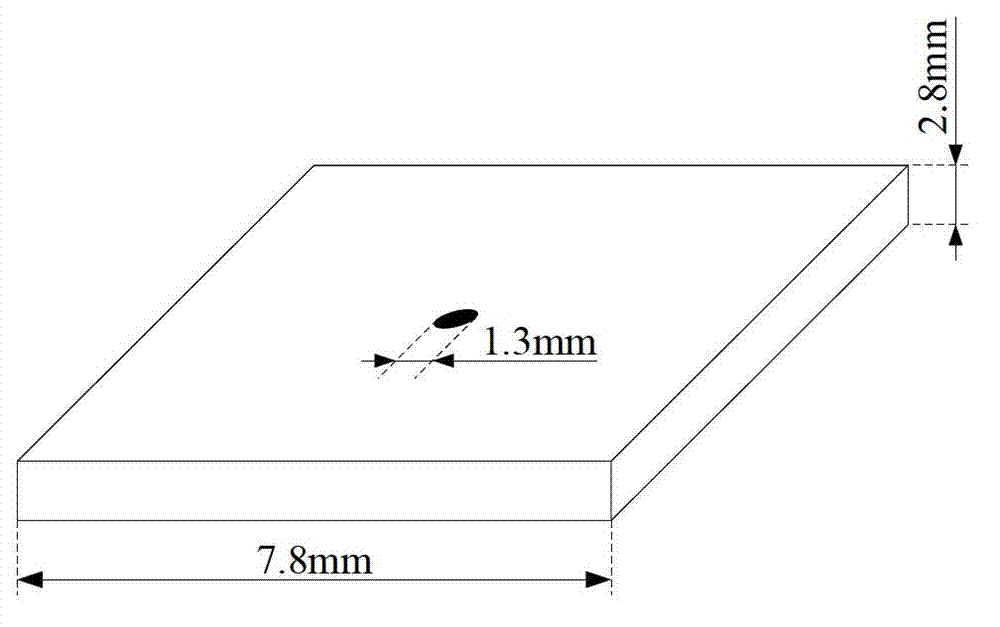

[0064] The inductance L in the test circuit is a low temperature co-fired ceramic LTCC inductance, which is a cube, such as figure 2 As shown, the micrometer measures the size of the inductor. The side length is 7.8mm and the thickness is 2.8mm. The through hole in the center of the inductor repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com