Weather-resistant vinyl chloride resin composition

A vinyl chloride-based resin and composition technology, applied in the field of vinyl chloride-based resin compositions for transparent products, can solve the problems of heat distortion temperature drop, coloring resistance becoming a problem, and transparency cannot be obtained, and achieve high transparency, Excellent coloring resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4、 comparative example 1~4

[0144] After using a Henschel mixer (Henschel mixer) to mix the ingredients listed in the following Table 1, use a double-drum forming machine (manufactured by Otake Machinery Industry Co., Ltd.), at a processing temperature of 170 ° C, a drum speed of 30 rpm, and a kneading time Roller kneading was carried out under the condition of 3 minutes, and a sheet having a length of 600 mm x a width of 300 mm x a thickness of 0.6 mm was produced.

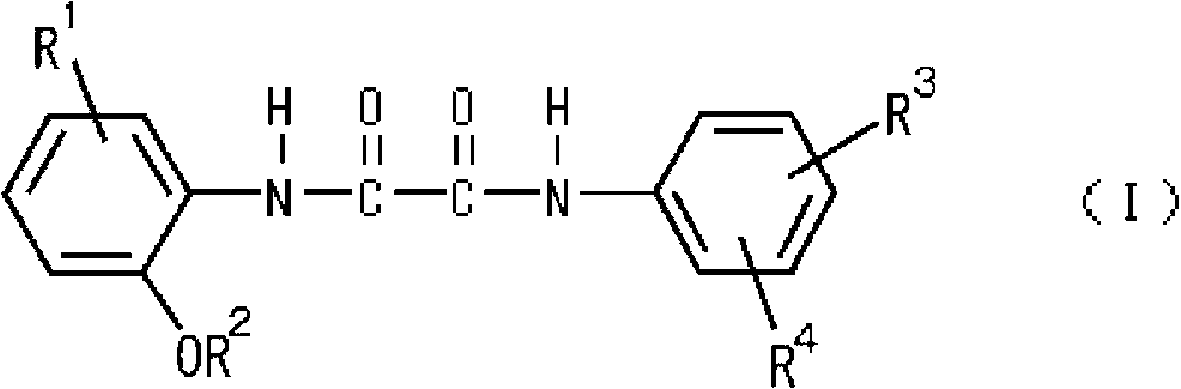

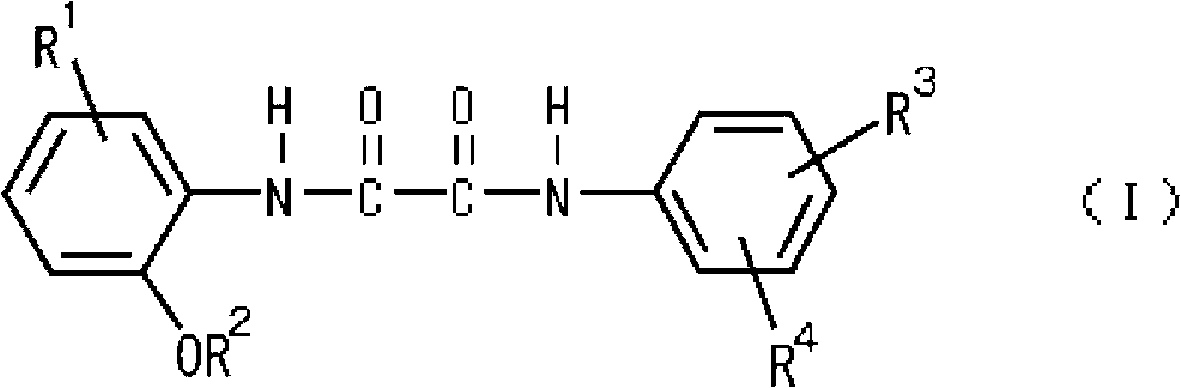

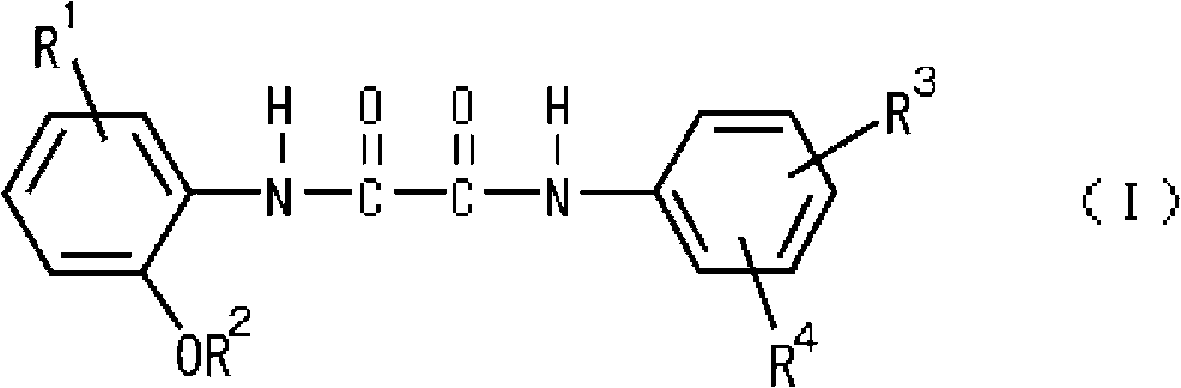

[0145] (C) The aniline oxalate type ultraviolet absorber described in Table 1 used the following compound No. 1.

[0146] Compound No.1

[0147]

[0148] In addition, as a comparative example, the following comparative compounds-1 and 2 were prepared as benzotriazole-based ultraviolet absorbers in place of (C) component in a composition without (C) component in the same manner, and as two A comparative compound-3 of a benzophenone-based ultraviolet absorber produced a sheet.

[0149] Comp-1

[0150]

[0151] Comp-2

[0152]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com