Super-high strength cold-rolled steel sheet having excellent bending properties

A cold-rolled steel sheet, ultra-high-strength technology, applied to furnace types, furnaces, heat treatment furnaces, etc., can solve problems such as insufficient bendability, achieve excellent bendability and delayed fracture resistance, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Hereinafter, the present invention will be specifically described based on examples, but the present invention is not limited to these examples.

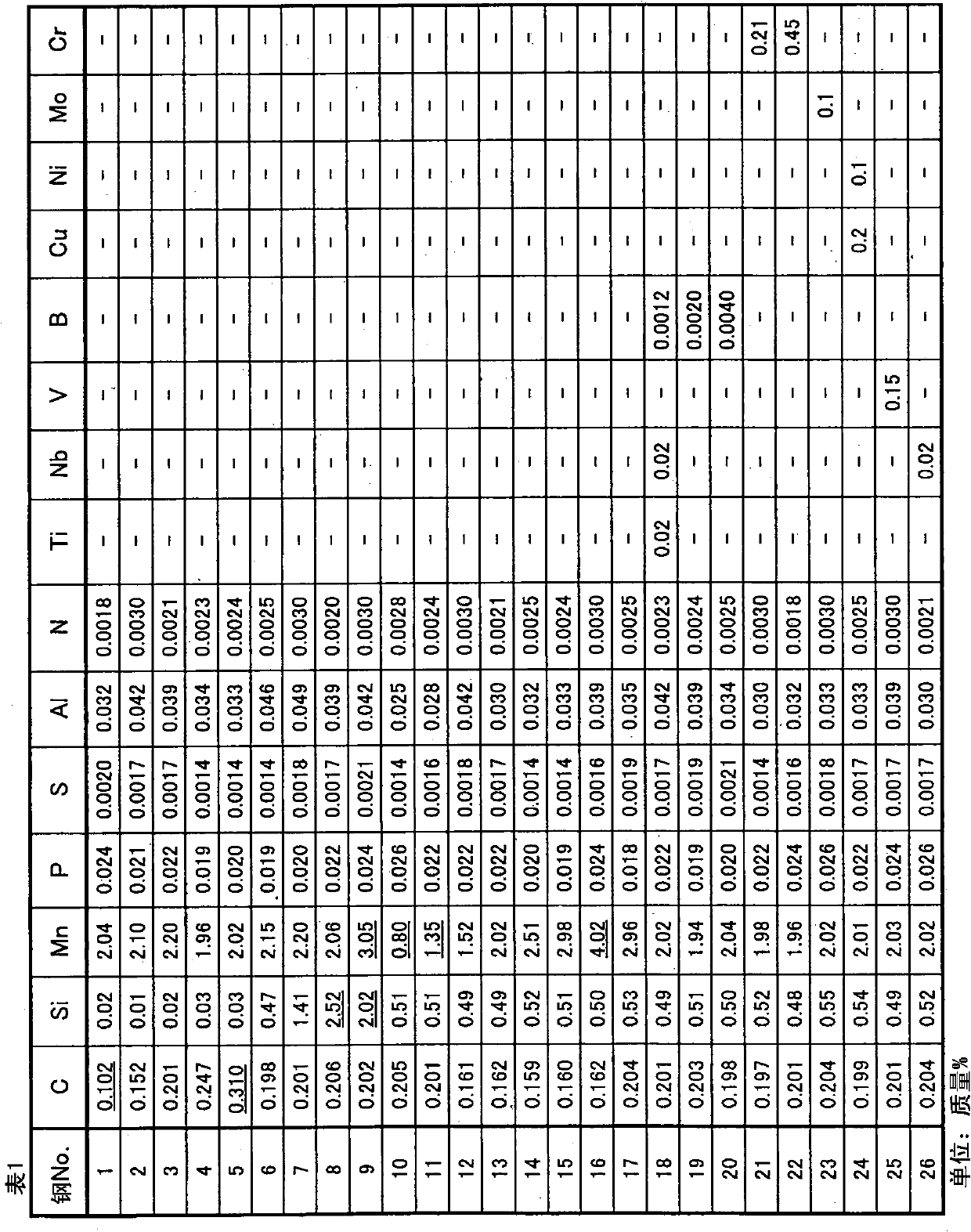

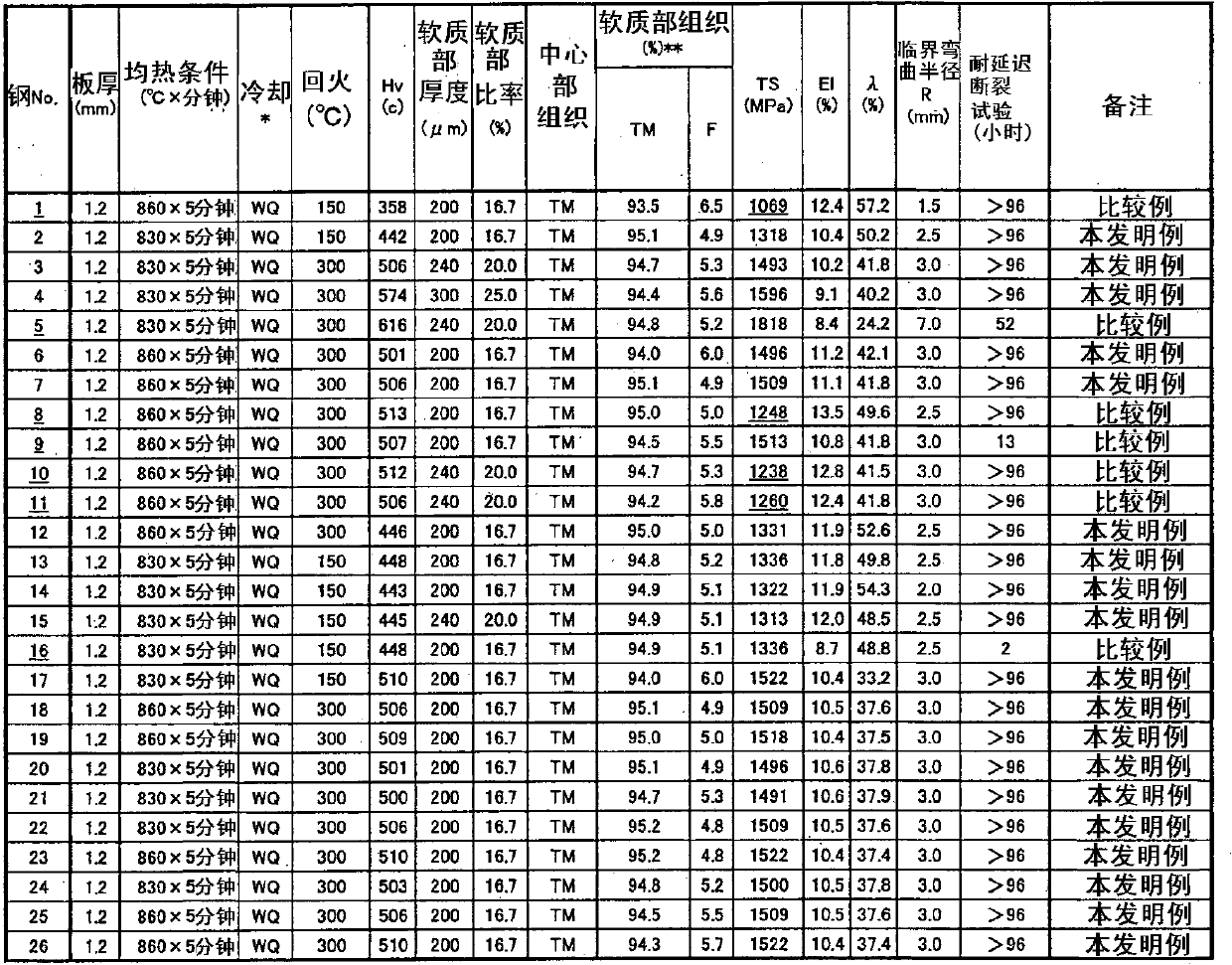

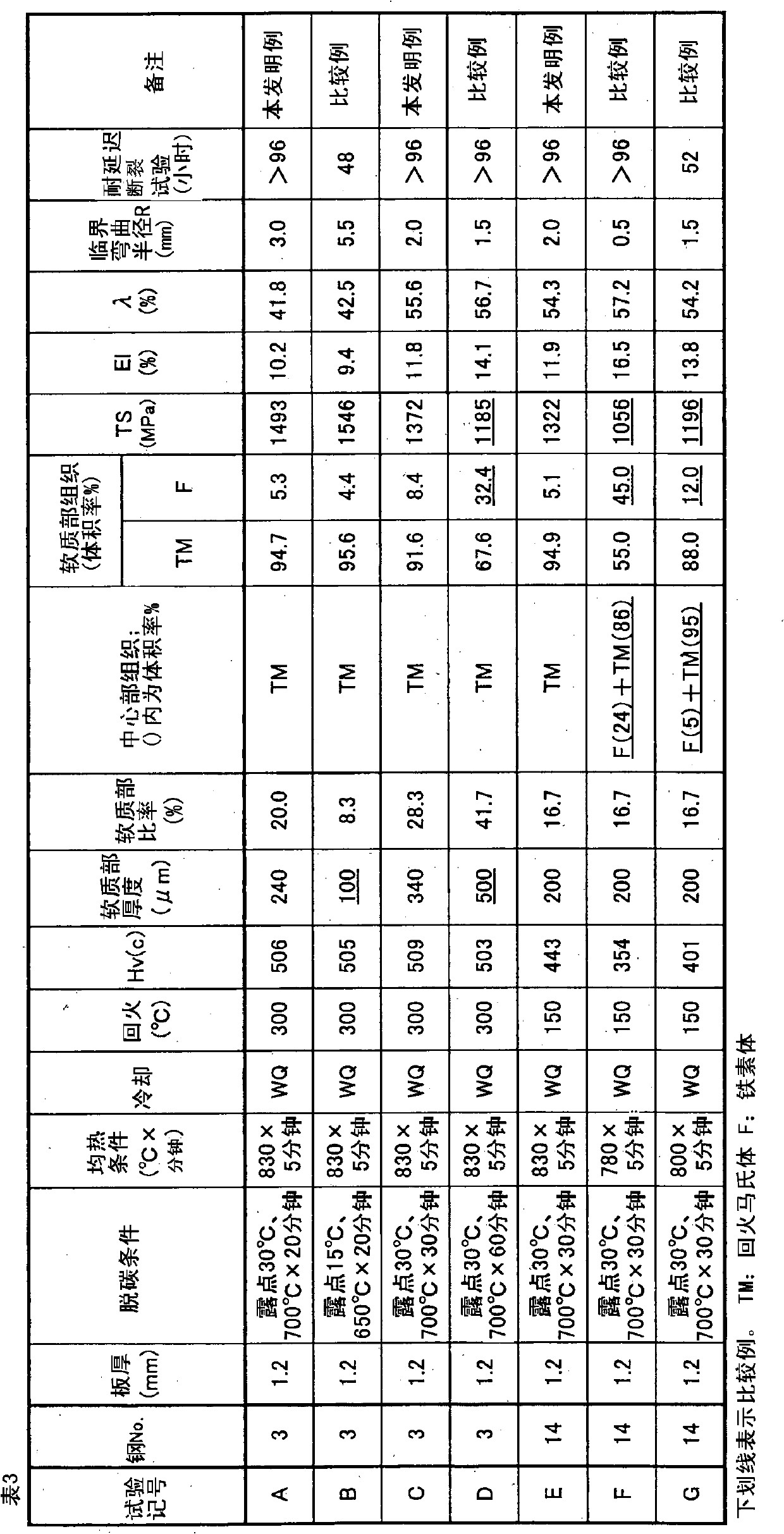

[0078]Steels having the compositions shown in Table 1 were melted and cast into slabs by continuous casting. Then, it is heated to 1200°C in a heating furnace, hot-rolled at a finish rolling temperature above 850°C, coiled at a temperature range of 500-650°C, pickled, cold-rolled, and then decarburized. Annealing and continuous annealing to make ultra-high-strength cold-rolled steel sheets. In addition, the decarburization annealing condition of the soft part of the surface layer of the steel plate is to implement heat treatment at 700-800°C for 15-60 minutes in a high dew point atmosphere. In addition, soaking, cooling, and tempering were performed under the conditions shown in Table 2 in continuous annealing. In addition, the components of the obtained steel sheets were analyzed, and the results were the same as in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com