Axial feeding type spiral conveying device and method

A technology of screw conveying device and screw conveyor, which is applied in the field of axial feed screw conveying device, can solve the problems of large gap between the inner diameter of the blade and the cylinder, easy disconnection of the welding position of the rotating shaft, and influence on the efficiency of the screw conveying, etc. Small power, convenient power transmission, and the effect of reducing oil resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

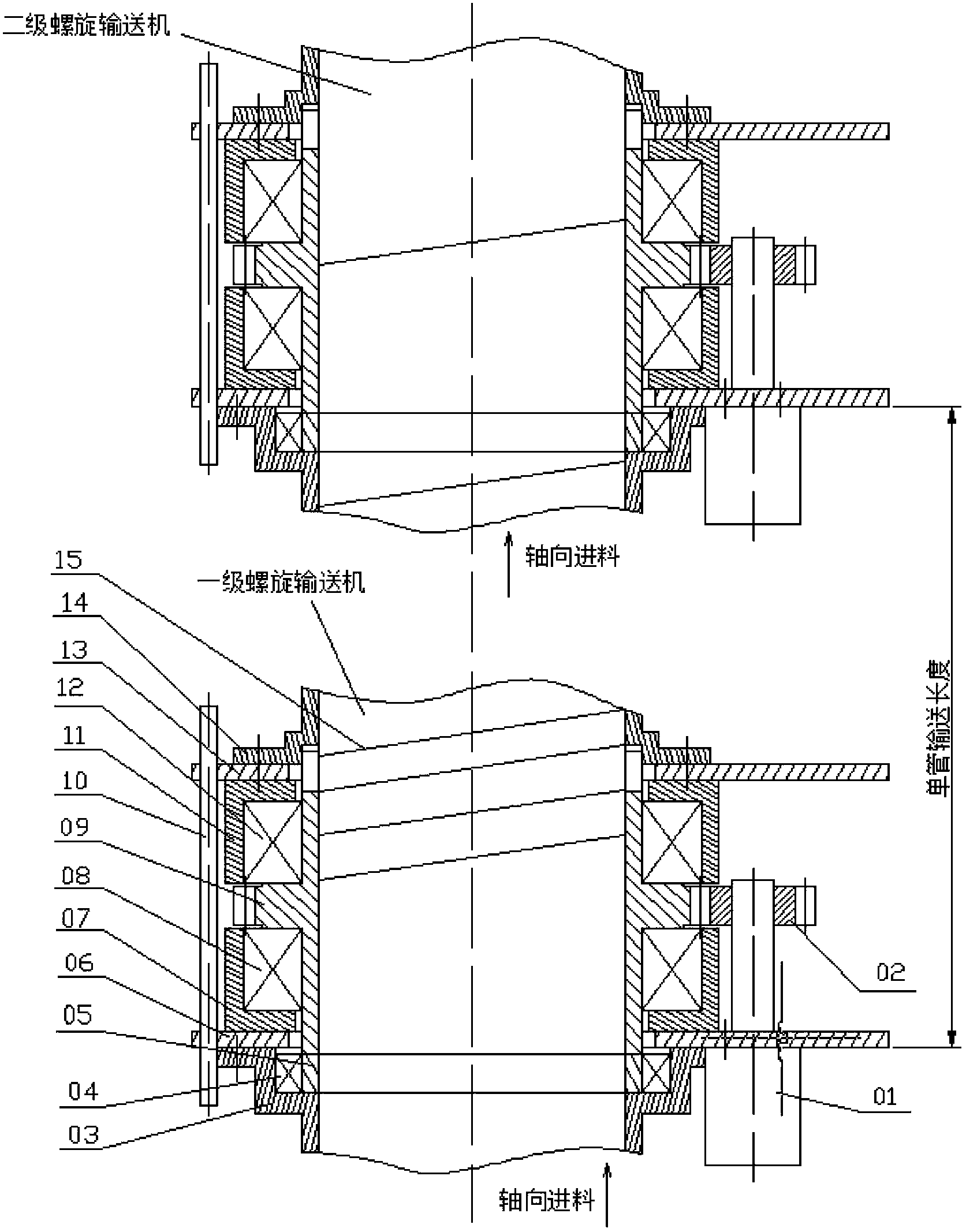

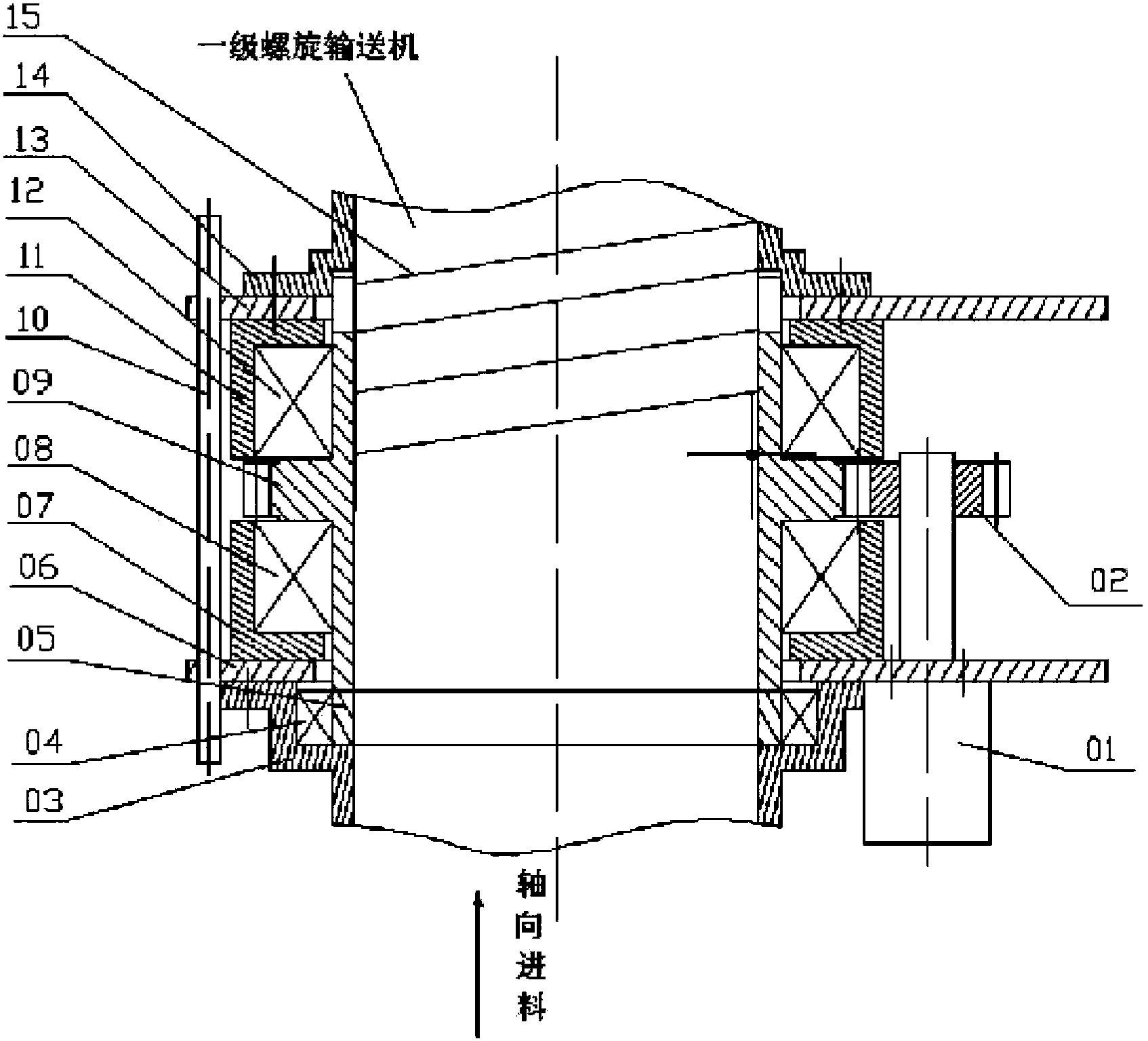

[0025] Such as figure 1 , 2 As shown, the axial feed screw conveyor is composed of multi-stage axial feed screw conveyors; each stage of axial feed screw conveyor includes a motor 01, a power input end 02, and a first spiral casing 03 , radial bearing 04, bearing bushing 05, first support plate 06, first thrust bearing seat 07, first thrust bearing 08, hollow rotating shaft 09, connecting rod 10, second thrust bearing seat 11, second thrust bearing 12. The second support plate 13, the second helical sleeve 14 and the helical blade shaft 15; the helical blade shaft 15 is a general helical blade for axial transmission, and the two ends of the helical blade are fixed on the hollow circular sleeve; the hollow Both ends of the rotating shaft 09 are respectively connected with the first spiral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com