Method for producing N2O4 (nitrogen tetroxide) through combining normal pressure diluted nitric acid, pressurized diluted nitric acid and concentrated nitric acid devices

A joint production and dilute nitric acid technology, which is applied in the direction of nitrogen dioxide, energy input, nitrogen oxides/oxyacids, etc., can solve the problem that idle and available equipment cannot be reused, the anti-risk ability is weakened, and the safety and environmental protection production of chemical enterprises cannot be satisfied. To achieve the effect of improving the ability to resist risks and market competitiveness, changing product structure and composition, and meeting market supply demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

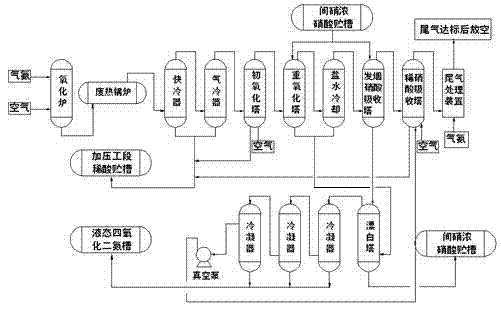

Image

Examples

Embodiment 1

[0024] This embodiment is the specific application of the present invention in Chongqing Sanling Chemical Fertilizer Co., Ltd., and its steps are as follows:

[0025] The first step: joint production of NO with atmospheric pressure dilute nitric acid, pressurized dilute nitric acid and concentrated nitric acid equipment 2 gas;

[0026] Specific steps:

[0027] The ammonia oxidation gas from the waste heat boiler of the atmospheric dilute nitric acid unit is cooled by the quick cooler and the gas cooler, and then enters the primary oxidation tower, and the NO in the gas is initially oxidized into NO by the secondary air from the blower. 2 , the oxidation rate is as high as 92%. At the same time, the "55%" nitric acid produced by the tower is pumped to the dilute acid storage tank in the pressurized nitric acid section for intermediate nitric acid production of concentrated nitric acid; the gas exiting the primary oxidation tower is re-oxidized Almost all of the tower is oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com