Water treatment device and method aiming at excessive ferrum, manganese, fluorine and arsenic in underground water

A water treatment device and groundwater technology, applied in the direction of contaminated groundwater/leachate treatment, oxidized water/sewage treatment, multi-stage water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

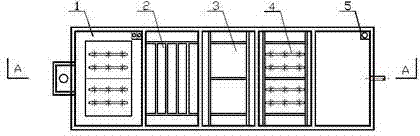

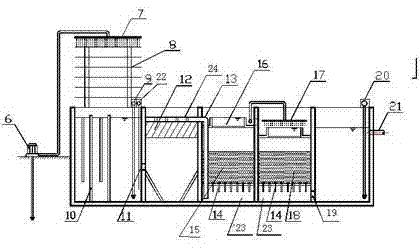

[0034] Depend on figure 1 and figure 2 It can be seen that a water treatment device for iron, manganese, fluorine and arsenic in groundwater exceeding the standard includes an inclined tube sedimentation tank 2 and a disinfection and clean water tank 5. The sand coarse filter material filter 3, the downward flow multi-media filter 4, the disinfection and the clear water tank 5 are sequentially connected to form;

[0035] The top of the clapboard oxidation reaction tank 1 is provided with a grid grid aeration tower 8 and a primary spray pipe 7, and the top is provided with a flocculant dosing pump 9 and a pH adjusting agent dosing pump 22; Partition 10;

[0036] The inclined tube settling tank 2 is provided with an inclined tube 12, and a water collection tank 24 is provided close to the upper part of the inclined tube 12; a water inlet 11 is provided on the side wall near the clapboard oxidation reaction tank 1;

[0037] The bottom of described upward flow quartz sand coar...

Embodiment 2

[0043] A water treatment method aimed at excessive levels of iron, manganese, fluorine and arsenic in groundwater, using the water treatment equipment described in Example 1, adopting "aeration → clapboard oxidation reaction → inclined tube precipitation → upward flow filtration → aeration → Downflow filtration" process for water treatment:

[0044] 1. Influent water quality: PH6.4, NTU (turbidity) 60, Fe 2+ 16.8mg / L, Mn 2+ 2.5mg / L, F - 2.9mg / L, As0.19mg / L, ammonia nitrogen 6.8mg / L, oxygen consumption 5.20mg / L.

[0045] 2. Control parameters:

[0046] (1) Separator oxidation reaction tank 1

[0047] PH=6~8, polyaluminum chloride according to F - :Al 3+ =1:8 mass ratio dosing, reaction time 30min.

[0048] (2) Inclined tube sedimentation tank 2

[0049] Precipitation time 4.5h.

[0050] (3) Upward flow quartz sand coarse filter material filter 3

[0051] The particle size of the filter material is 0.71~2.0mm, the filtration rate is 8~10m / h, and the filtra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com