Gas detection method

A technology of gas detection and gas detector, which is applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of limiting the practicality of ionization gas sensors, etc., and achieve the reduction of discharge current, good detection repeatability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

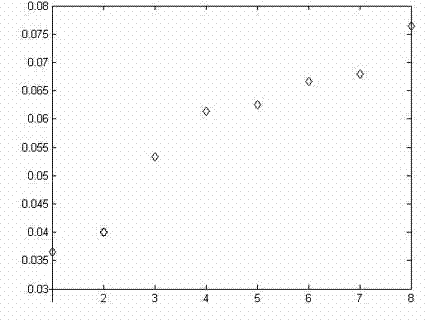

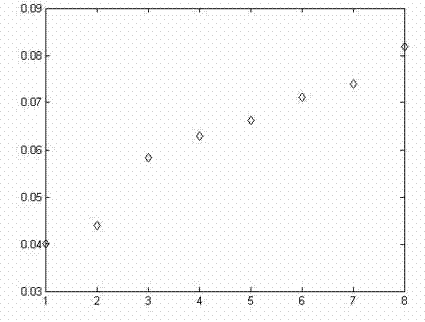

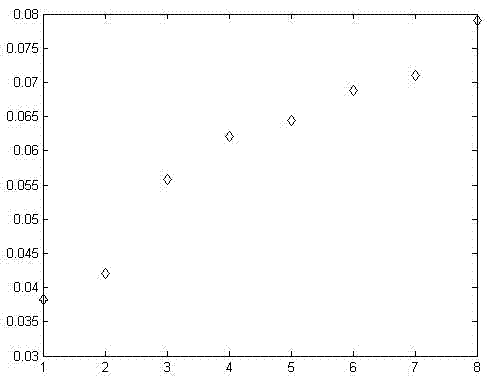

[0033] The invention provides a gas detection method, which is used for a gas detector to detect the concentration or type of the gas to be measured. figure 1 Shown is a schematic diagram of the gas detector provided by the present invention. figure 2 Shown is a coordinate diagram of the detection data set of the anode sensor in an embodiment of the present invention. image 3 Shown is a coordinate diagram of the detection data set of the cathode sensor in the embodiment of the present invention. Figure 4 Shown is a coordinate diagram of the detection data sets of all the gas sensors in the embodiment of the present invention. Figure 5 Shown is the coordinate diagram of the fitted detection conductance curve in the embodiment of the present invention. Image 6 Shown is a schematic block diagram of the modulated stochastic resonance system provided by the present invention. Figure 7 Shown is a graph of the signal-to-noise ratio curve in the described embodiment of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com