Method for producing pharmaceutical dimeticone

A production method and technology of simethicone, which is applied in the production field of pharmaceutical simethicone, can solve the problems of excessive phenyl compounds, excessive water content, low relative density, etc., and achieve high activity, low production cost and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

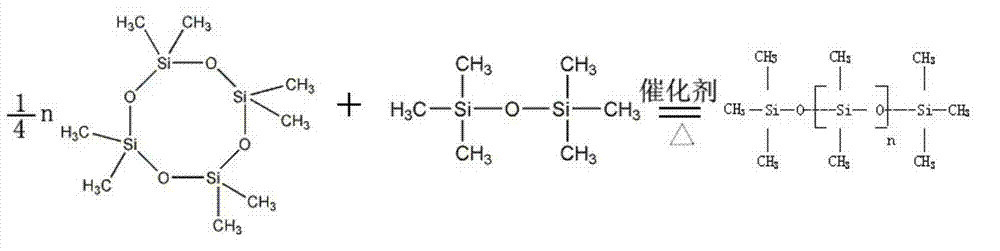

Method used

Image

Examples

Embodiment 1

[0033] (1) Dehydrate the catalyst-LDX-604 type large pore size strong acid cation exchange resin (purchased from Jiangsu Nantong Taihelai Chemical Co., Ltd.), and vacuum dry it at 80 °C until nearly anhydrous, and the vacuum degree is ≤-0.06MP a , stored at low temperature (<-8℃) for later use.

[0034] (2) Add 300g of octamethylcyclotetrasiloxane and 15g of hexamethyldisiloxane after filtering into the mixing tank, stir and mix for 10 minutes, then put the mixed material into the measuring tank, and put it in the measuring tank. The mixture was heated to 90°C.

[0035] (3) with N 2 The mixture in the metering tank is pressed into the catalytic reactor containing 55g of LDX-604 type large-pore strong acid cation exchange resin pretreated in step 1). The temperature of the mixed material was at 90°C, and a positive displacement pump was used to circulate the material in the catalytic reactor for 1.5 hours. After the reaction, crude simethicone was obtained.

[0036] (4) wit...

Embodiment 2

[0038] (1) Dehydrate the catalyst-732 type strong acid styrene cation exchange resin (purchased from Wenxian Kaibiyuan Water Purification Material Factory), and vacuum dry it at 85°C until nearly anhydrous, with a vacuum degree of ≤-0.06MP a , stored at low temperature (<-8℃) for later use.

[0039](1) Add 320Kg of octamethylcyclotetrasiloxane and 10Kg of hexamethyldisiloxane after filtration into the mixing tank, stir and mix for 15 minutes, then put the mixed material into the measuring tank, and put it in the measuring tank. The mixture was heated to 92.5°C.

[0040] (2) with N 2 The mixture in the metering tank is pressed into the catalytic reactor containing the 62Kg 732 type strongly acidic styrene cation exchange resin pretreated in step 1), and the volume coefficient of the catalyst filling is 32%. The temperature was 95°C, and a positive displacement pump was used to circulate the material in the catalytic reactor for 1.25 hours. After the reaction, crude simethico...

Embodiment 3

[0043] (1) Dehydrate the catalyst-D001 type large pore size strong acid styrene cation exchange resin (purchased from Shanghai Kaiping Resin Co., Ltd.), and vacuum dry it at 90°C until nearly anhydrous, and the vacuum degree is ≤-0.06MP a , stored at low temperature (<-8℃) for later use.

[0044] (2) Add 321Kg of octamethylcyclotetrasiloxane and 12Kg of hexamethyldisiloxane after filtration into the mixing tank, stir and mix for 20 minutes, then put the mixed material into the measuring tank, and put it in the measuring tank. The mixture was heated to 95°C.

[0045] (3) with N 2 The mixture in the metering tank is pressed into the catalytic reactor containing the 70Kg D001-200 type large-pore strong acid styrene cation exchange resin pretreated in step 1, the volume coefficient of the catalyst filling is 35%, and the volume coefficient in the catalytic reactor is controlled. The temperature of the mixed material was 100°C, and a positive displacement pump was used to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com