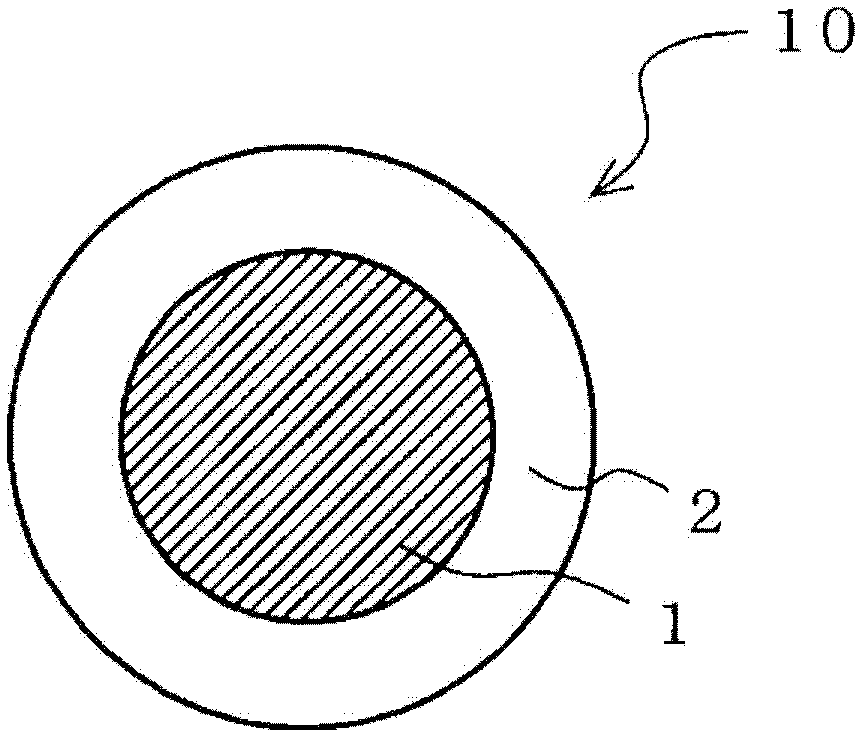

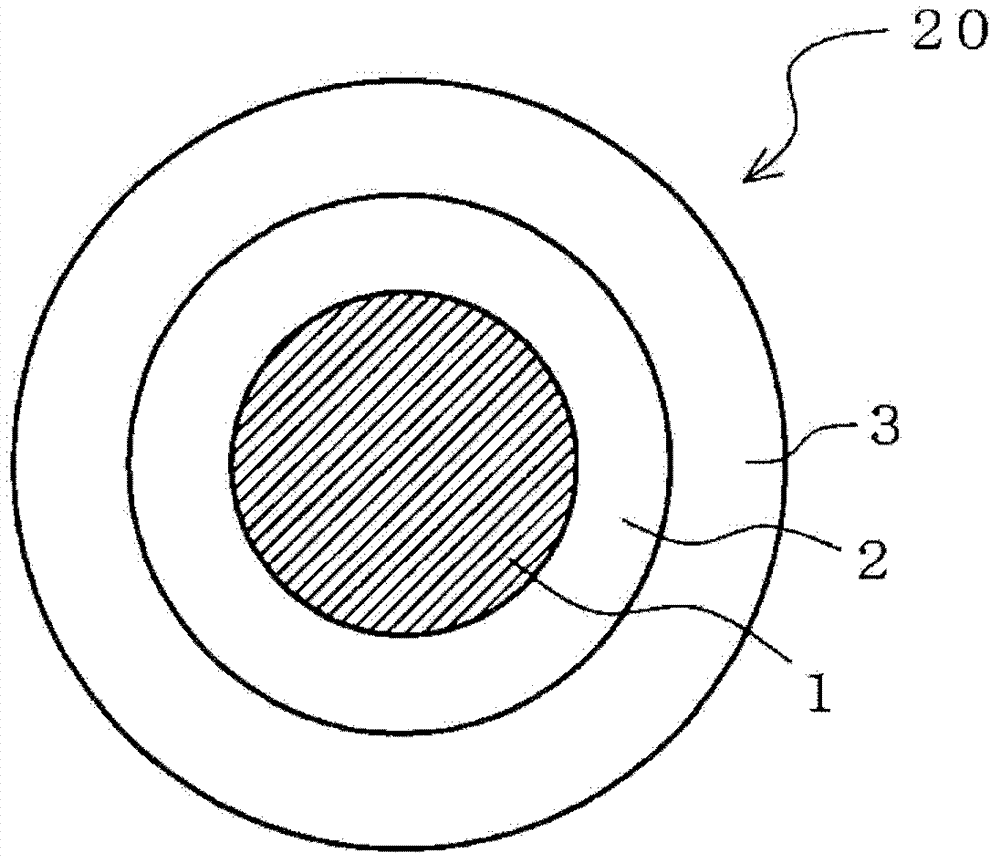

Resin composition, and wire and cable using the same

一种树脂组合物、硅烷化合物的技术,应用在电线,电缆领域,能够解决变形、不合格等问题,达到交联速度优异、高交联度、挤出外观平滑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

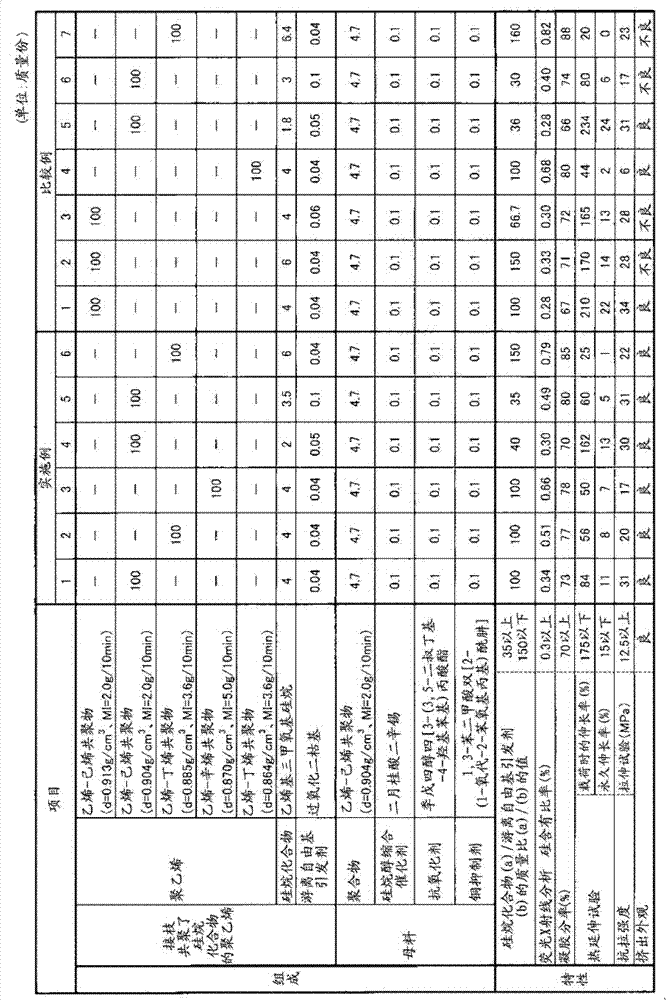

[0061] Hereinafter, Examples 1 to 6 and Comparative Examples 1 to 7 of the present invention will be described.

[0062] In Examples 1-6 and Comparative Examples 1-7, the resin composition which has silane crosslinked polyethylene as a main component was produced. The step of graft-copolymerizing the silane compound and polyethylene, and the step of kneading the silanol condensation catalyst and extrusion-coating the copper conductor were carried out separately.

[0063] First, in the process of graft-copolymerizing the silane compound and polyethylene, use a 40mm single-screw extruder (L / D=24), add polyethylene from the hopper, and inject it into vinyltrimethoxysilane by a liquid filling pump. A solution in which dicumyl peroxide was dissolved was produced to produce polyethylene in which a silane compound was graft-copolymerized. Extrusion was carried out so that the cylinder temperature was set to 200° C. and the residence time in the extruder was 2 to 3 minutes.

[0064]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com