Pressure stabilizing device for highly-filled wood-plastic composite material pelletizing mould head

A wood-plastic composite material and granulation die head technology, which is applied in the field of high-fill wood-plastic composite material granulation die head voltage stabilizing device, can solve the problems of unstable head pressure and poor fluidity, and achieve the goal of ensuring the pressure of the head Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

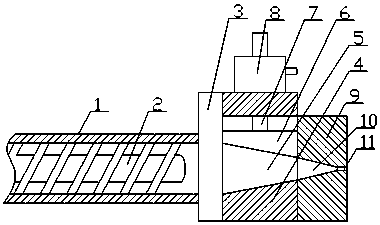

[0019] Such as figure 1 As shown, the high-filling wood-plastic composite material granulation die pressure stabilizing device includes a barrel 1, a screw 2, a flange 3, a transition body 4, a storage chamber 5, a pressing piston 6, a pressing rod 7, a hydraulic cylinder 8, Pelletizing die head 9, converging runner 10, discharge port 11.

[0020] The screw 2 is set inside the barrel 1, and the end of the barrel 1 is connected to the transition body 4 through the flange 3; the transition body 4 is provided with a conical storage chamber 5, and a dynamic movable compression chamber is provided on the side of the storage chamber 5. The piston 6 and the compression piston 6 are connected to the hydraulic cylinder 8 through the compression rod 7, and the hydraulic cylinder 8 maintains a stable pressure on the contact surface of the compression piston 6 and the composite material melt through dynamic pressure.

[0021] The pelletizing die head 9 is provided with a tapered convergi...

Embodiment 2

[0023] This example discloses the working principle of the high-filling wood-plastic composite material granulation die head voltage stabilizing device:

[0024] When the highly filled wood-plastic composite material melt containing water vapor enters the storage chamber 5 in the transition body 4 under the mixing and conveying action of the screw 2, it is dynamically released by the compression piston 6 in the storage chamber 5, To ensure the stability of the melt pressure in the material storage chamber 5, as the melt is continuously conveyed forward, the material is compacted. The pressure caused by the periodic movement of the screw 2 is balanced with the dynamic pressure of the compression piston 6 in the material storage chamber 5, so that the pressure of the material entering the pelletizing die 9 is stable, and the strip can be extruded normally and stably.

[0025] The present invention aims at the problem of heavy moisture and unstable die head pressure in the granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com