Rust-containing coating curing agent and preparation method thereof

A curing agent and coating technology, used in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid amides, etc., can solve problems such as health hazards of workers, floating rust, etc. Conducive to the effect of low requirements on construction and curing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

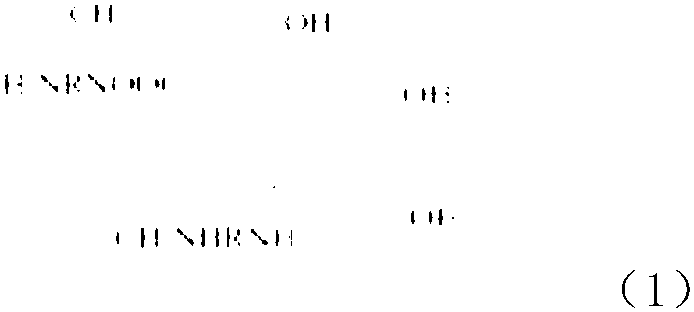

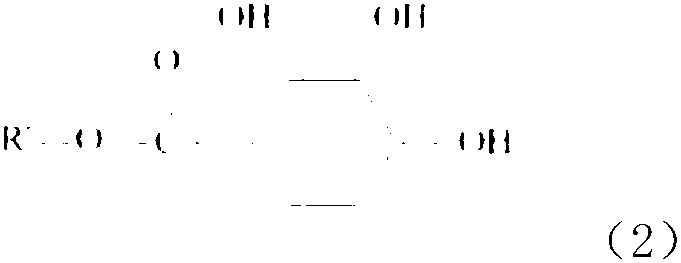

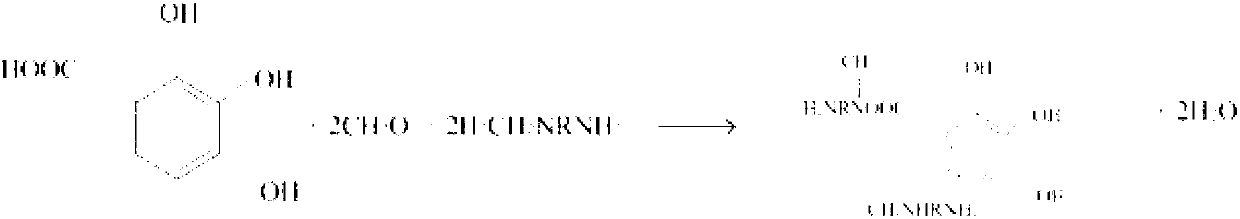

Method used

Image

Examples

Embodiment 1

[0026] In the 500ml four-necked reaction flask that is equipped with stirrer, condenser, thermometer, dropping funnel and nitrogen pipe, add 340 grams of gallic acid, constantly stir and pass into N 2 React under air, drop 120 grams of diaminoethane at a temperature of 35 ° C, keep the temperature at 30 ° C after the dropwise addition, then add 163 grams of 37% formaldehyde solution dropwise, after the dropwise addition, heat up to 81 ° C , keep warm for 4 hours, add the chain terminator acrylonitrile, dehydrate under reduced pressure, the theoretical dehydration amount is 36 grams, the actual dehydration amount is 32 grams, and the product A is obtained by cooling and collecting; the amine value of product A=461, the active hydrogen equivalent on the amine group 81.

Embodiment 2

[0028] The operation method is the same as in Example 1, and the raw materials are input: 340 grams of gallic acid, 149 grams of diaminopropane, and 163 grams of 37% formaldehyde solution to obtain product B. The amine value of product B=432, and the active hydrogen equivalent on the amine group is 86.

Embodiment 3

[0030] The operation method is the same as in Example 1, and the raw materials are input: 340 grams of gallic acid, 176 grams of diaminobutane, and 163 grams of 37% formaldehyde solution to obtain product C. The amine value of product C=415, and the active hydrogen equivalent on the amine group is 90.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com