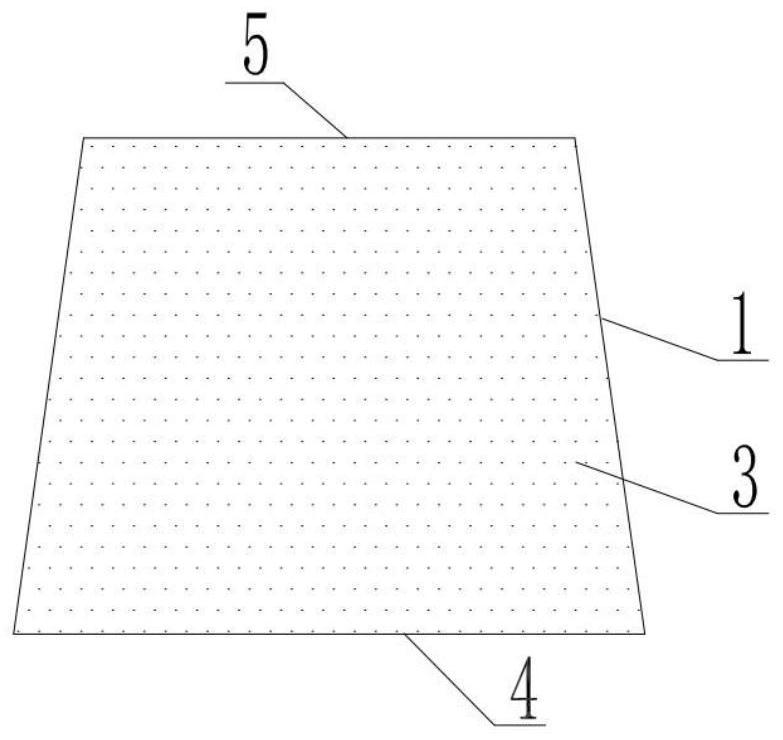

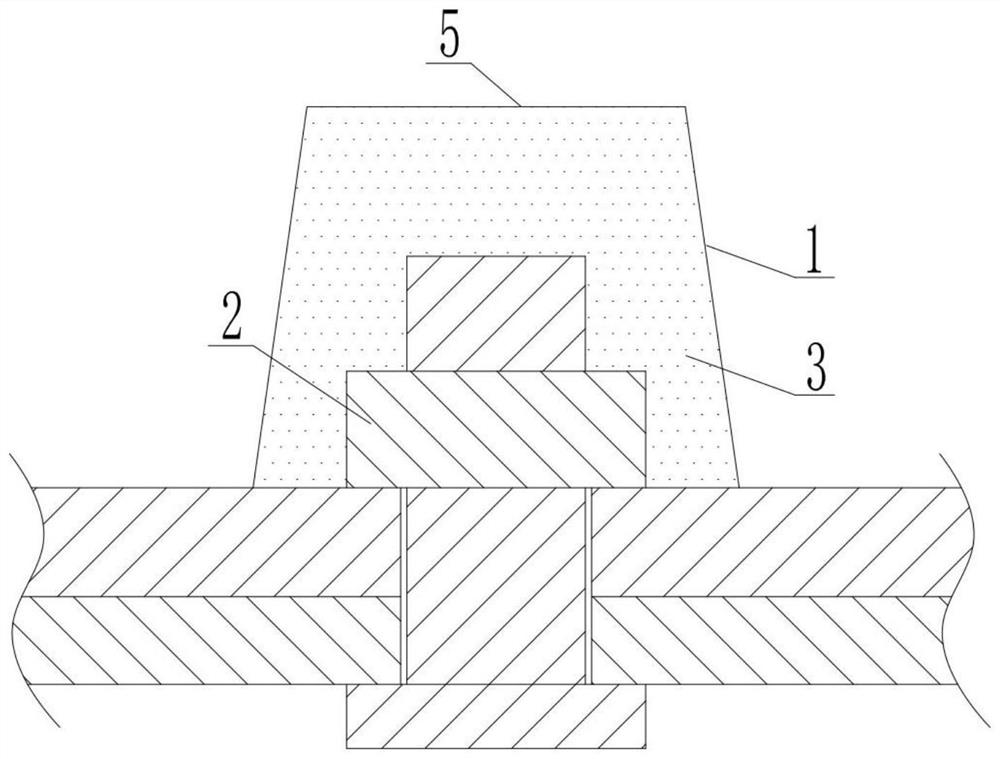

Protective sealing material and preparation and construction method thereof

A technology of sealing material and rubber material, applied in the field of protective sealing material and its preparation and construction, can solve the problems of water resistance, easy corrosion of exposed nuts, troublesome replacement, etc., and achieve the effects of short process, shortened preparation period and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

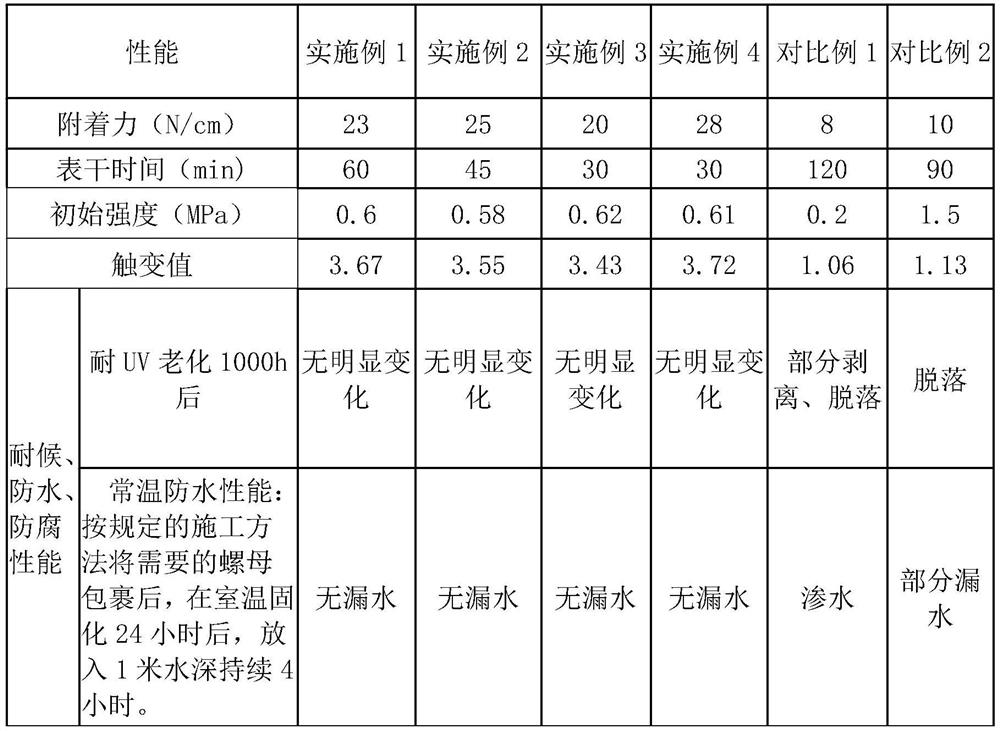

Examples

Embodiment 1

[0048] Pretreatment of raw materials, 100 parts of α, ω-terminated hydroxyl polydimethylsiloxane (kinetic viscosity η = 1000cp), 10 parts of dimethyl silicone oil, 3 parts of hydrophobic fumed silica TS-720, 10 parts of hollow Hollow glass microspheres and 0.2 parts of colored carbon black were placed in an oven at 120°C to dry for 8 hours, and set aside.

[0049] The rubber is kneaded and mixed, and the pretreated α, ω-terminated hydroxyl polydimethylsiloxane and dimethyl silicone oil are put into the cavity of the vacuum kneader at one time, and the blade speed of the kneader is adjusted, and heated to 120°C, after polydimethylsiloxane and dimethyl silicone oil are mixed evenly, add fumed white carbon black, hollow glass microspheres, and colored carbon black powder raw materials in 3 times, and make sure that each time the powder is added The materials in the cavity have been kneaded into a paste. After the powder is added, start the vacuum pump, maintain the vacuum at -0....

Embodiment 2

[0053] Pretreatment of raw materials, 90 parts of α, ω-terminated hydroxyl polydimethylsiloxane (kinetic viscosity η = 1000cp), 15 parts of dimethyl silicone oil, 4 parts of hydrophobic fumed silica TS-720, 15 parts of hollow The glass microspheres and 0.4 parts of colored carbon black were placed in an oven at 120°C for 10 hours and dried for later use.

[0054] The rubber is kneaded and mixed, and the pretreated α, ω-terminated hydroxyl polydimethylsiloxane and dimethyl silicone oil are put into the cavity of the vacuum kneader at one time, and the blade speed of the kneader is adjusted, and heated to 110°C, after polydimethylsiloxane and dimethyl silicone oil are mixed evenly, add fumed white carbon black, hollow hollow glass microspheres, and colored carbon black powder in 4 times. The materials in the material cavity have been kneaded into a paste. After the powder is added, start the vacuum pump, maintain the vacuum at -0.1Mpa, and continue kneading and mixing for 1.5h....

Embodiment 3

[0057] Pretreatment of raw materials, 80 parts of α, ω-terminated hydroxyl polydimethylsiloxane (kinetic viscosity η = 1000cp), 20 parts of dimethyl silicone oil, 5 parts of hydrophobic fumed silica TS-720, 20 parts of hollow The glass microspheres and 0.6 parts of colored carbon black were placed in an oven at 120°C for 12 hours and dried for later use.

[0058] The rubber is kneaded and mixed, and the pretreated α, ω-terminated hydroxyl polydimethylsiloxane and dimethyl silicone oil are put into the cavity of the vacuum kneader at one time, and the blade speed of the kneader is adjusted, and heated to 100°C, after polydimethylsiloxane and dimethyl silicone oil are mixed evenly, add fumed white carbon black, hollow glass microspheres, and colored carbon black powder in 5 times. The materials in the cavity have been kneaded into a paste. After the powder is added, start the vacuum pump, maintain the vacuum at -0.1Mpa, and continue kneading and mixing for 1 hour. Then the rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com