High-frequency low-impedance electrolytic capacitor

An electrolytic capacitor and low-impedance technology, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve problems such as poor corrosion resistance, poor high-frequency characteristics, and short service life, and achieve excellent corrosion resistance and suppress leakage current The effect of recovery and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

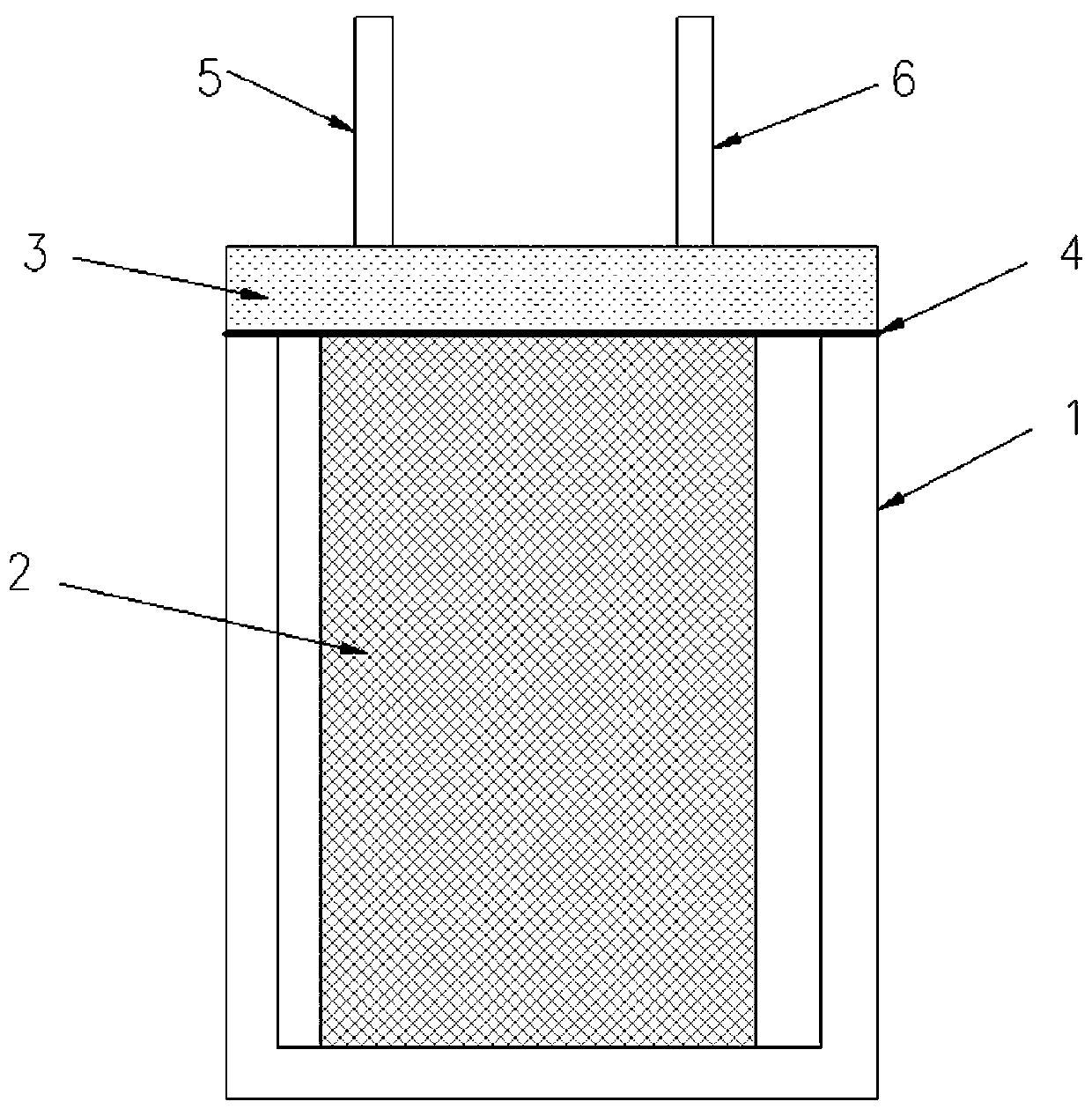

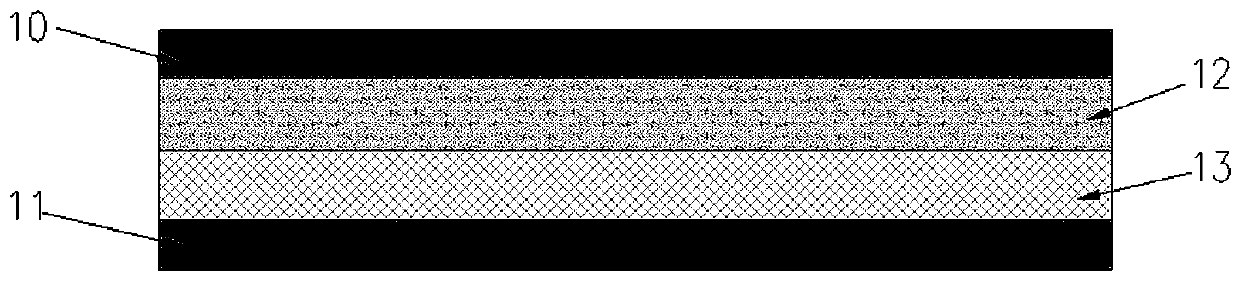

[0020] see Figure 1-2 , the present invention provides a technical solution: a high-frequency low-impedance electrolytic capacitor, including an outer shell 1, the outer shell 1 adopts a hollow cylindrical structure, the inner cavity of the outer shell 1 is equipped with a core pack 2, and the outer shell The body 1 is open, and an insulating cover 3 is installed at the opening of the upper end of the outer shell 1. The inner side of the insulating cover 3 is covered with a layer of protective film 4. The insulating cover 3 is provided with two through holes. The positive pin 5 and the negative pin 6 are respectively inserted into the two through holes, and the positive pin 5 and the negative pin 6 are electrically connected to the positive end and the negative end of the core pack 2 respectively.

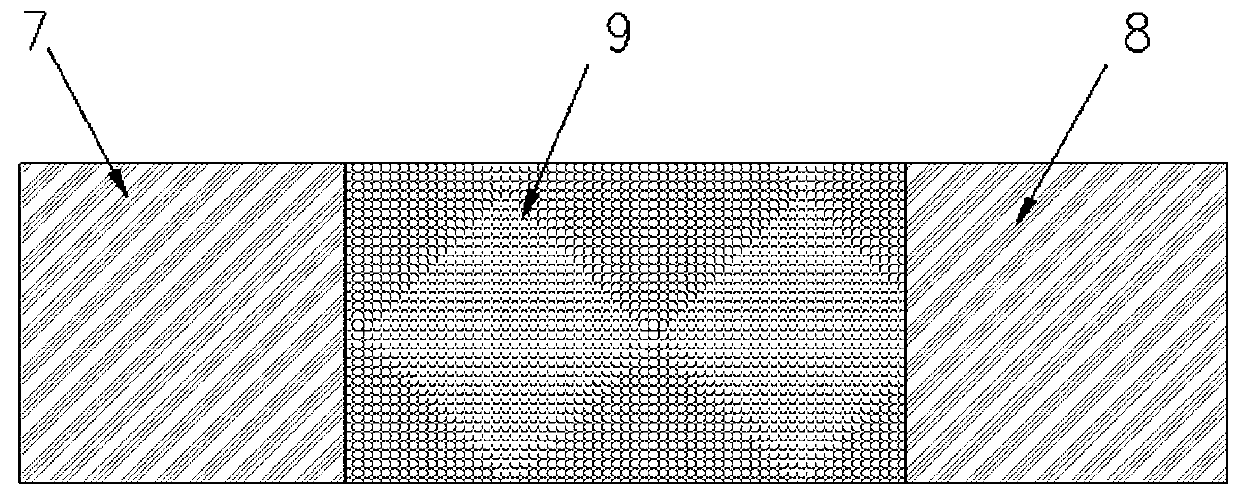

[0021] In the present invention, the core package 2 includes positive electrode foil 7, negative electrode foil 8 and electrolytic paper 9, the positive electrode foil 7, negative...

Embodiment 2

[0025] see Figure 1-2 , the present invention provides a technical solution: a high-frequency low-impedance electrolytic capacitor, including an outer shell 1, the outer shell 1 adopts a hollow cylindrical structure, the inner cavity of the outer shell 1 is equipped with a core pack 2, and the outer shell The body 1 is open, and an insulating cover 3 is installed at the opening of the upper end of the outer shell 1. The inner side of the insulating cover 3 is covered with a layer of protective film 4. The insulating cover 3 is provided with two through holes. The positive pin 5 and the negative pin 6 are respectively inserted into the two through holes, and the positive pin 5 and the negative pin 6 are electrically connected to the positive end and the negative end of the core pack 2 respectively.

[0026] In the present invention, the core package 2 includes positive electrode foil 7, negative electrode foil 8 and electrolytic paper 9, the positive electrode foil 7, negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com