Pure calcium cored wire for steelmaking

A pure calcium cored wire and coating technology, applied in the field of cored wire, can solve the problems of calcium bubbles floating, weak slag penetration ability, serious splashing, etc., to reduce the formation of calcium bubbles, increase the absorption time, penetrate Ability Increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

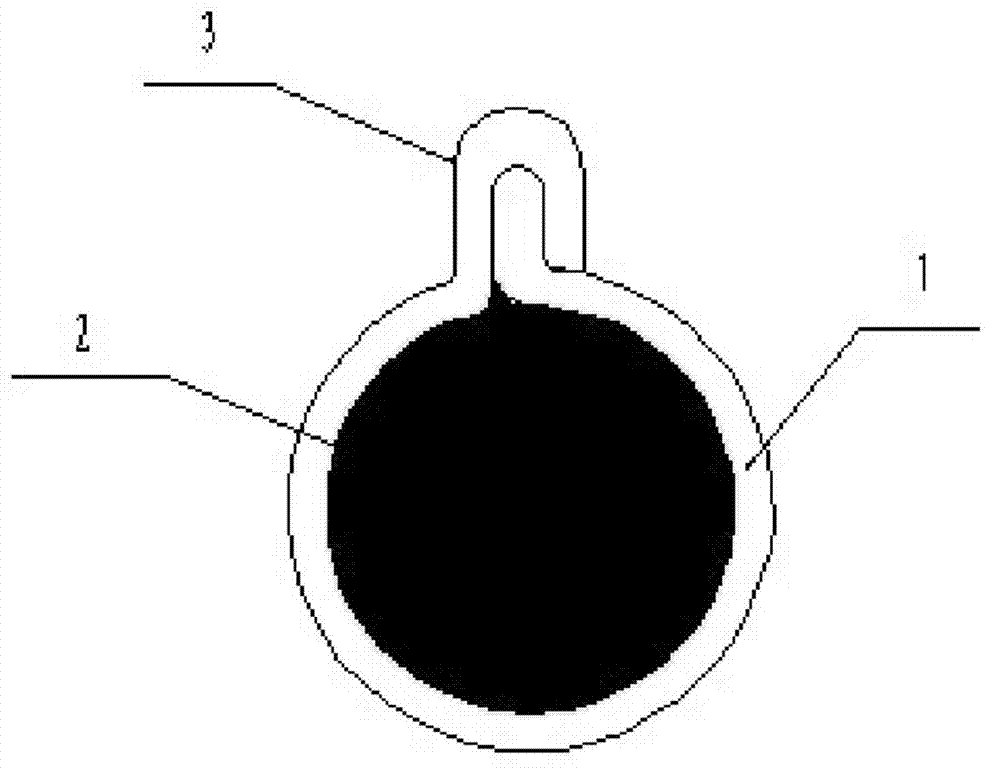

[0014] Refer to the attached figure 1 A pure calcium cored wire for steelmaking according to the present invention will be described in detail below.

[0015] A pure calcium cored wire for steelmaking according to the present invention has a structure comprising an outer cladding layer 1 and a cladding core body 2 wrapped in the outer cladding layer 1, and the surface of the outer cladding layer 1 is provided with vertical The edge 3, the vertical edge 3 is perpendicular to the tangent line of the circular section of the outer cladding layer 1, and the thickness of the outer cladding layer 1 is 0.75-2.0 mm.

[0016] The outer cladding layer 1 is a cold-rolled steel strip above SPCC level, with a thickness of 1.2 mm.

[0017] The thickness of the vertical rib 3 is 3.6mm.

[0018] The coated core 2 is a solid calcium metal strip with a purity of ≥97%.

[0019] The diameter of the clad core 2 is 6.6mm.

[0020] After passing through the edges, crimps, and pressing of each set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com