Method for producing high-quality low-sulfur steel by using aluminium and calcium premelted refining slag

A refining slag and pre-melting technology, applied in the direction of improving process efficiency, etc., can solve the problems of impossible deep desulfurization, insufficient aluminum content to reduce oxides, and increase costs, so as to achieve stable desulfurization effect without affecting production rhythm, and reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail. Before that, it should be noted that the terms or words used in this specification and the claims should not be interpreted as the ordinary meaning or the meaning in the dictionary, but should be based on the best way to explain the inventors of the invention. The principle of properly defining the concepts of the terms is interpreted as meanings and concepts that conform to the technical idea of the present invention. Accordingly, the structure shown in the embodiment described in this specification is only one of the best embodiments of the present invention, and cannot fully represent the technical idea of the present invention. Therefore, it should be understood that there may be alternatives for the present invention. Various equivalents and modifications.

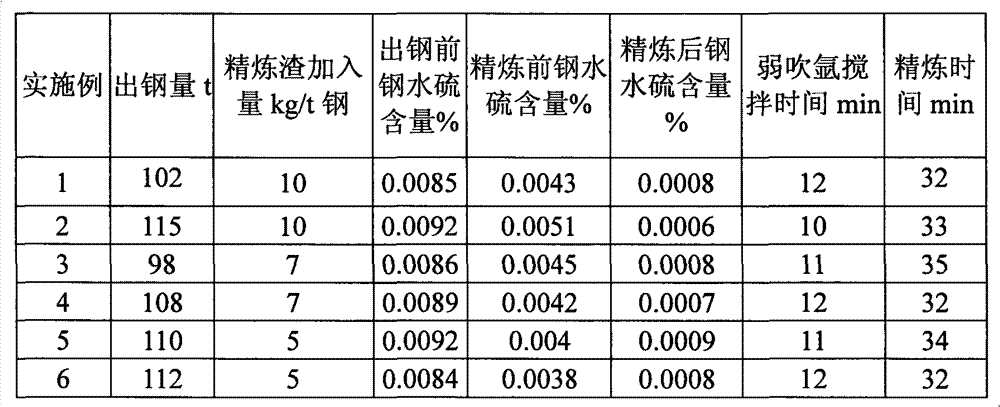

[0027] Table 1 shows the implementation effect of using iron-calcium premelting refining slag to produce high-qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com