Diesel engine exhaust waste heat double-effect recovery system

A technology of exhaust waste heat and recovery system, applied in exhaust devices, mechanical equipment, steam engine devices, etc., can solve problems such as little help and cannot significantly reduce exhaust temperature, and achieve safe and efficient recovery and reduction of NOx emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

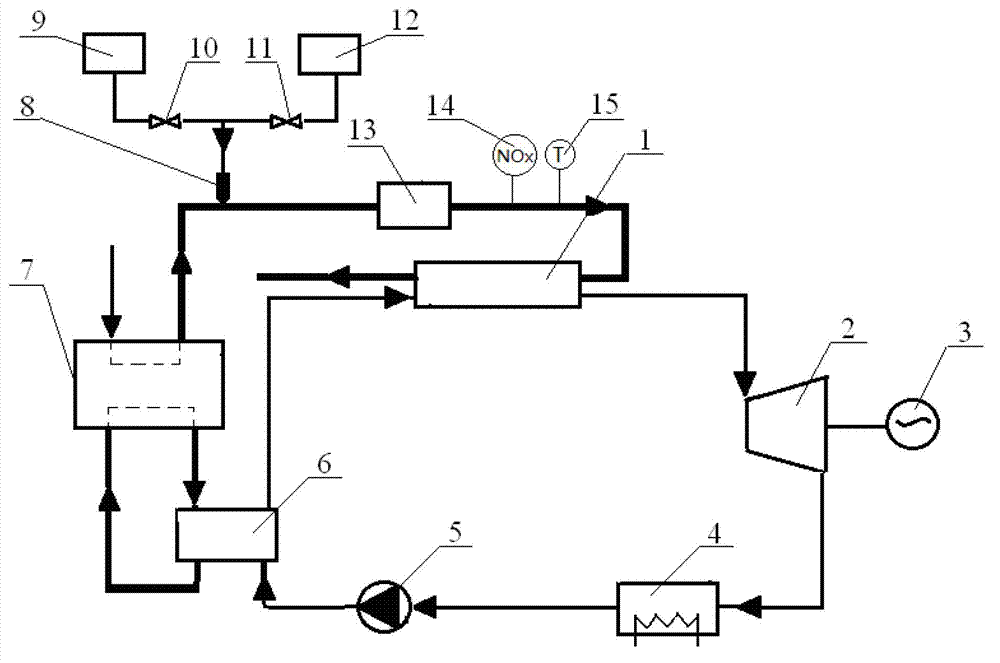

[0011] The principle and system of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is illustrative rather than restrictive, and does not limit the protection scope of the present invention.

[0012] Diesel engine exhaust waste heat double-effect recovery system, the system is composed of: steam turbine 2 and generator 3-axis connection, evaporator 1 working medium side, steam turbine 2, condenser 4 working medium side, working medium pump 5 and preheater 6 The working fluid side is connected in turn to form an organic Rankine cycle thermal power generation system. The exhaust pipe of the engine 7 is connected to the gas side of the evaporator through the SCR catalytic reduction device 13 , and the reagent box 9 is connected to the left bypass valve 10 . The water tank 12 is connected with a right bypass valve 11, and the left and right bypass valves are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com