Standard sample for analyzing 82B wire rod sorbite content and preparation method thereof

A standard sample and sorbite technology, which is applied in the preparation of test samples, material analysis, and material analysis through optical means, can solve problems such as large analysis errors, cumbersome operations, and inability to perform quantitative analysis, and achieve operational Ease of operation, improved accuracy, good traceability and data reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

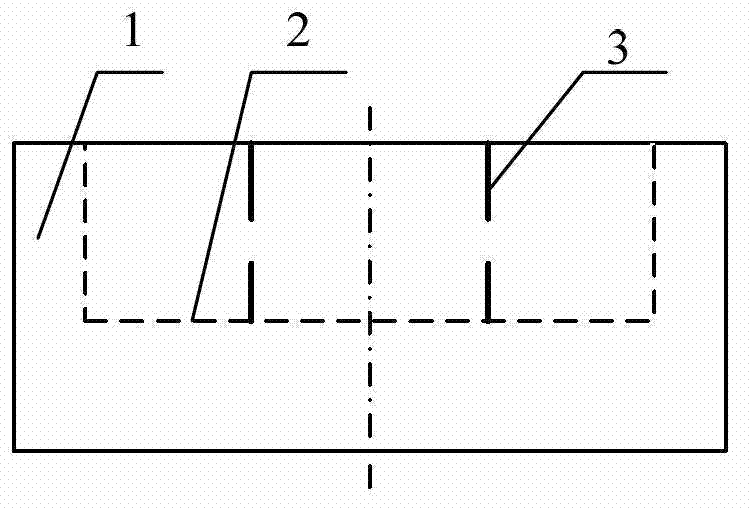

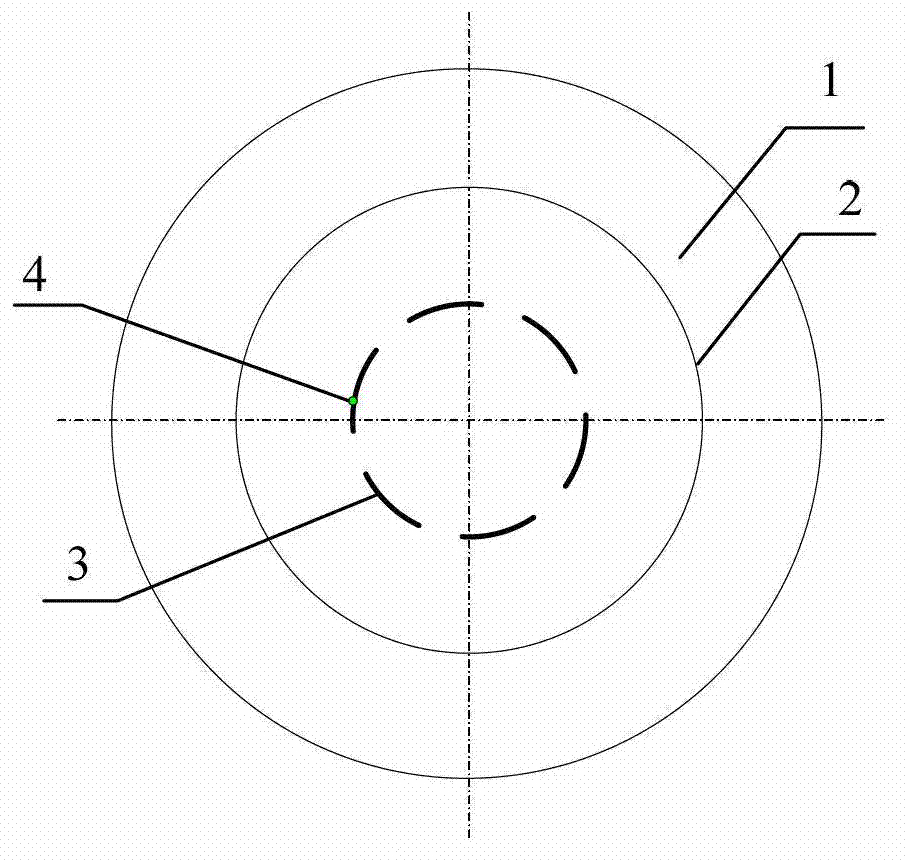

[0029] like figure 1 and figure 2 As shown, it is a wire rod metallographic sample, and the standard sample 2 is embedded in the standard sample mounting material 1.

[0030] A standard sample for 82B wire rod sorbite content analysis, containing the following chemical elements in weight percent:

[0031] C: 0.80-0.85, Si: 0.10-0.30, Mn: 0.30-0.90,

[0032] P≦0.025, S≦0.025, Cr≦0.35, Ni≦0.10,

[0033] Cu≦0.20, S≦0.025, V≦0.15;

[0034] The metallographic structure of the standard sample is mainly sorbite, containing a small amount of non-sorbite structure. The distribution of sorbite is uniform on the analysis ring 3 of the standard sample cross-section R0.5, and in the standard sample thickness direction R0. 5 analysis ring 3 is also u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com