Multi-speed servo system and speed switching method

A technology of speed switching and servo system, applied in the direction of control system, single motor speed/torque control, electrical components, etc., can solve the problems of energy waste, low transmission efficiency, bulky, etc., and achieve the expansion of speed range and optimal configuration , the effect of expanding the torque range and speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific embodiments of the present invention are now described with reference to the accompanying drawings. It is used to indicate various connection relationships related to the present invention, but not to limit their actual spatial position relationships.

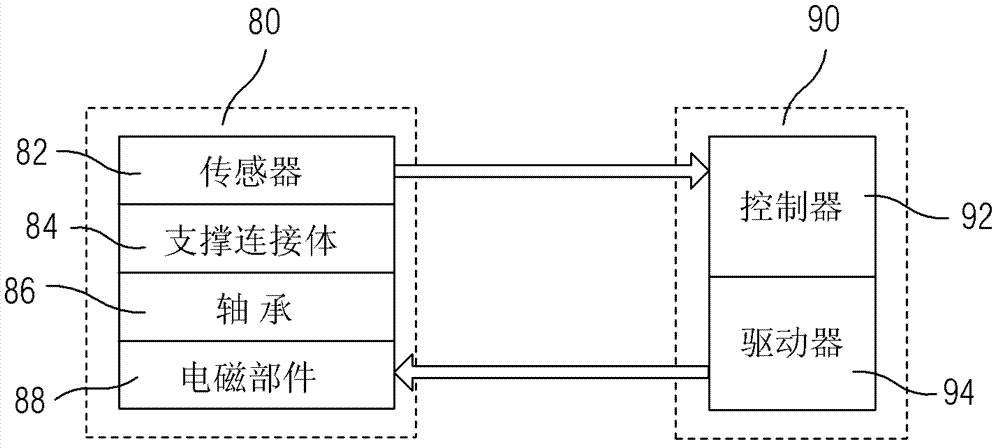

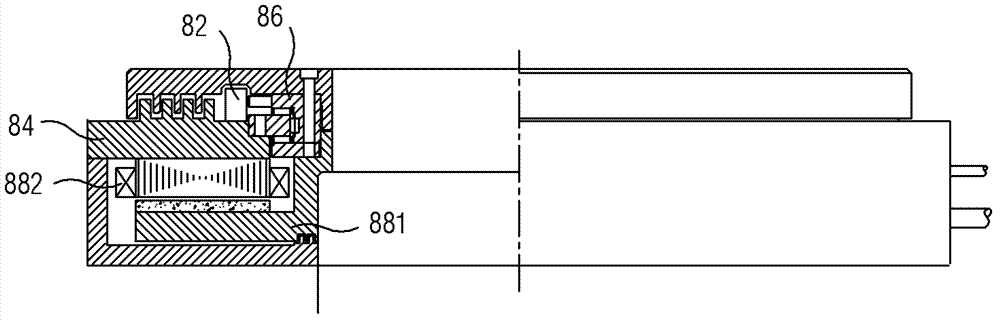

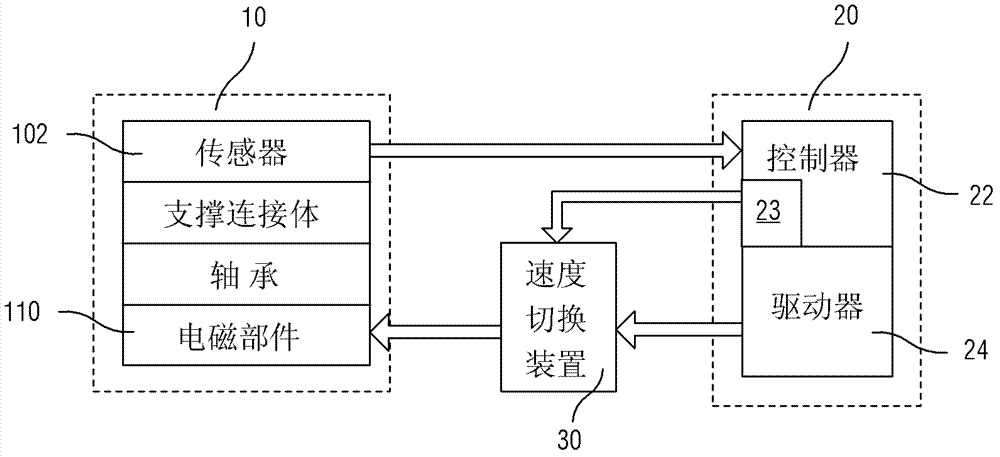

[0085] image 3 Shown is a structural schematic diagram of a specific exemplary embodiment of a multi-speed servo system. Such as image 3 As shown, the multi-speed servo system includes a servo motor 10 , a servo control device 20 and a speed switching device 30 . image 3 The same parts as the existing servo system will not be repeated. The servo control device 20 includes a controller 22, a driver 24, and a switching module 23. The controller 22 includes a switching module 23. The switching module 23 can receive a speed switching instruction and output a switching signal. The speed switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com