Wastewater treating device of kitchen wastewater recycling flow

A technology for wastewater treatment and kitchen wastewater, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, climate change adaptation, etc. It can solve problems such as low product quality, environmental pollution, and failure to meet standards. Achieve the effects of increasing production, realizing resource utilization, and preventing secondary environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

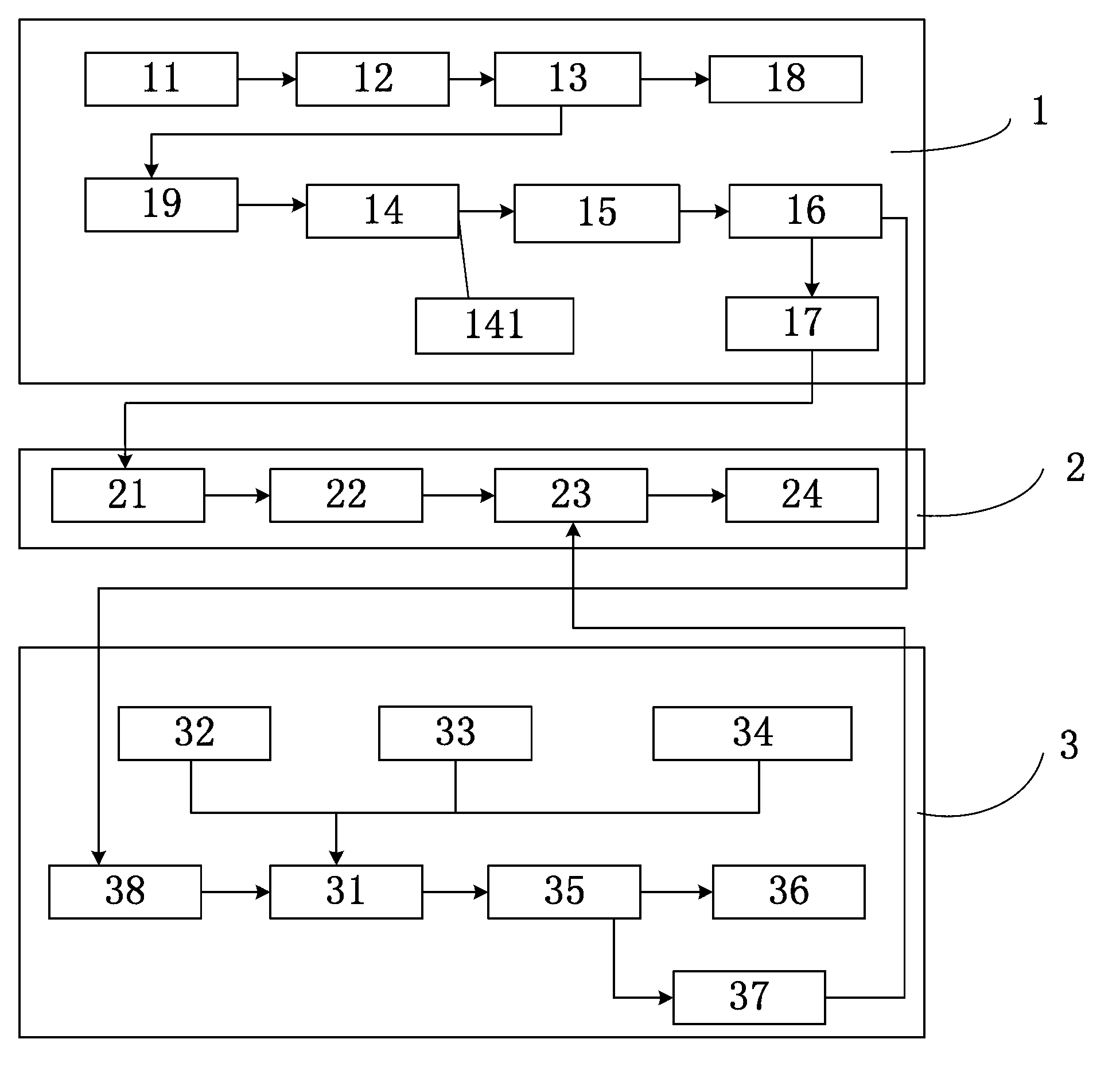

[0039] A wastewater treatment device for a kitchen wastewater recycling process, such as figure 1 shown, including:

[0040] The liquid fertilizer manufacturing department 1 heats and stirs the waste water generated in the kitchen waste resource treatment process, makes the waste water rotate at a speed of 4000-6000 rpm, and separates oil, waste water and sludge, and uses microorganisms to make the separated waste water Fermentation is carried out at a speed of 4000-6000rpm, and the generated microorganisms and treated water are separated by precipitation;

[0041] Fermentation and compost manufacturing part 2, the liquid fertilizer that described liquid fertilizer manufacturing part transports, mixes coconut bran,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com