Method for extracting, separating and purifying flax lignans from flax cakes

A technology of flax lignans and flax cakes, which is applied in the fields of chemical instruments and methods, organic chemistry, sugar derivative preparation, etc., can solve the problems of low extraction temperature, harsh conditions, high cost, etc., and achieve simple process operation and low condition requirements High, relatively high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

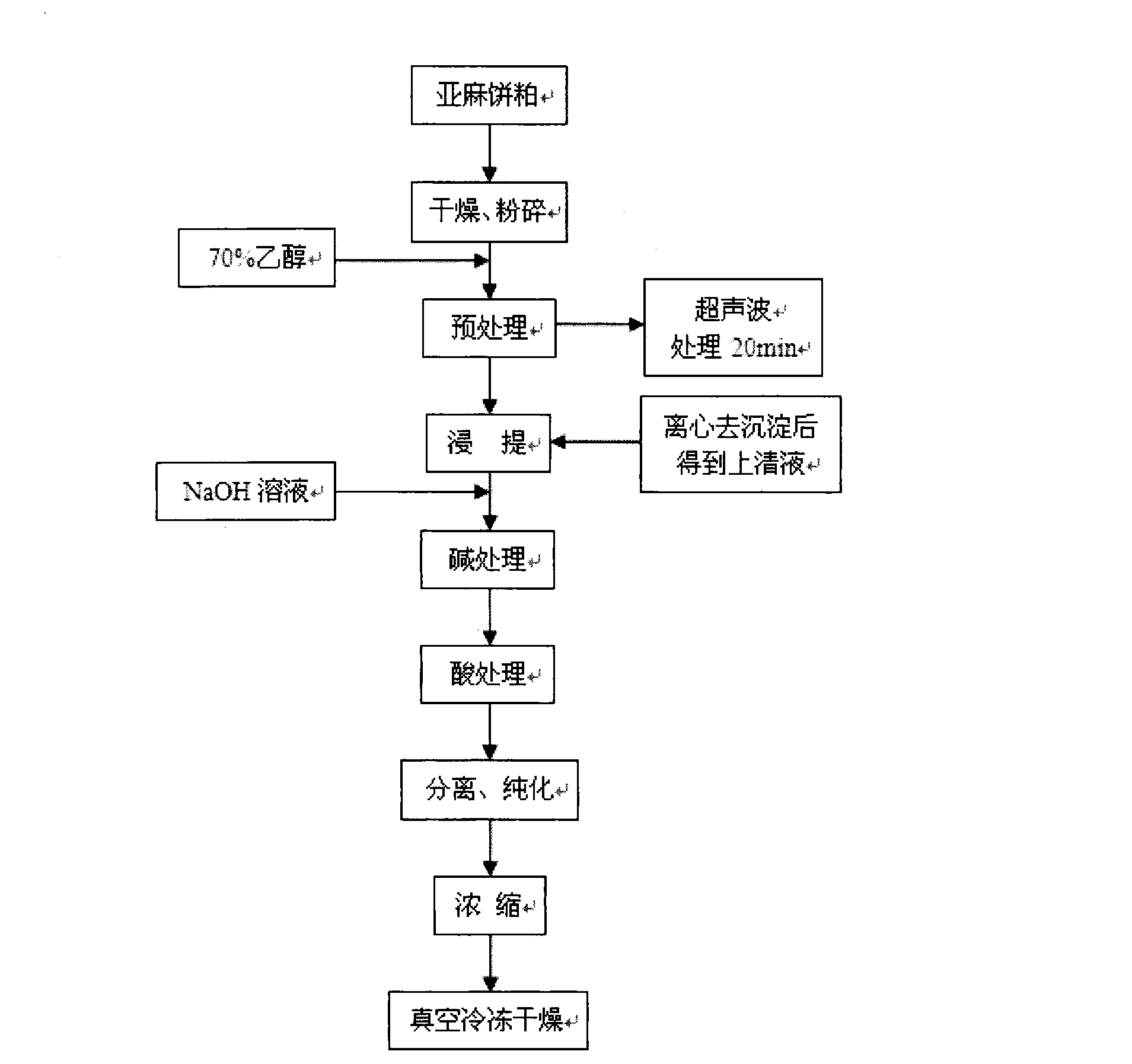

Method used

Image

Examples

Embodiment 1

[0029] (1) After crushing the dried flax cake, pass it through a 100-mesh sieve, weigh 100g, add an appropriate amount of 70% ethanol solution 500ml, seal and soak for 1.5h, put it in an ultrasonic device, set the power to 300W, and the temperature to room temperature , treated for 20 minutes, then continued to stir and extract, and after 3 hours, centrifuged at 1500rmp for 10 minutes to remove the precipitate and obtain the supernatant;

[0030] (2) Add NaOH solution to the supernatant obtained in the previous step to adjust pH=12, stir and extract for 2.5h, keep pH=12 constant in this process, centrifuge at 3000rmp for 10min, neutralize the supernatant with HCl solution, and adjust the pH to 4.0;

[0031] (3) The crude extract obtained in the previous step is adsorbed through AB-8 type macroporous resin chromatography, and the flow velocity is controlled at 0.5cm / min;

[0032] (4) Elute with 20% ethanol solution to obtain an alcohol solution containing flax lignans, concent...

Embodiment 2

[0034] (1) After crushing the dried flax cake, pass through a 100-mesh sieve, weigh 100g, add an appropriate amount of 60% ethanol solution 800ml, seal and soak for 1 hour, place in an ultrasonic device, set the power to 300W, and the temperature to room temperature, Treat for 30 minutes, then continue to stir and extract. After 3.5 hours, centrifuge at 1500rmp for 5 minutes to remove the precipitate and obtain the supernatant;

[0035] (2) Add NaOH solution to the supernatant obtained in the previous step to adjust pH=12.5, stir and extract for 2h, keep pH=12.5 unchanged in this process, centrifuge at 3000rmp for 10min, neutralize the supernatant with HCl solution, and adjust the pH to 4.2;

[0036] (3) The crude extract obtained in the previous step is adsorbed through AB-8 macroporous resin chromatography, and the flow rate is controlled at 0.5cm / min;

[0037] (4) Elute with 20% ethanol solution to obtain an alcohol solution containing flax lignans, concentrate in a vacuum...

Embodiment 3

[0039] (1) After crushing the dried flax cake, pass it through a 100-mesh sieve, weigh 100g, add an appropriate amount of 50% ethanol solution 1000ml, seal and soak for 0.5h, put it in an ultrasonic device, set the power to 300W, and the temperature to room temperature , treated for 40 minutes, then continued stirring and leaching, and after 4 hours, centrifuged at 1500rmp for 5 minutes to remove the precipitate and obtain the supernatant;

[0040] (2) Add NaOH solution to the supernatant obtained in the previous step to adjust pH=11.5, stir and extract for 1.5h, keep pH=11.5 constant in this process, centrifuge at 3000rmp for 10min, neutralize the supernatant with HCl solution, and adjust the pH to 4.5;

[0041] (3) The crude extract obtained in the previous step is adsorbed through AB-8 macroporous resin chromatography, and the flow rate is controlled at 0.5cm / min;

[0042] (4) Elute with 20% ethanol solution to obtain an alcohol solution containing flax lignans, concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com