Compound intumescent flame retardant and preparation method thereof

An intumescent flame retardant and composite technology, applied in the field of intumescent flame retardants and their preparation, can solve the problems of difficult dispersibility and interfacial force, deteriorating physical and mechanical properties, affecting flame retardant properties, etc., and achieve excellent thermal oxygen shielding. effect, good flame retardant effect, thermal and mechanical properties improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

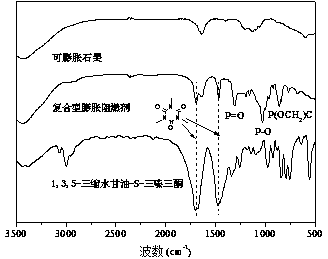

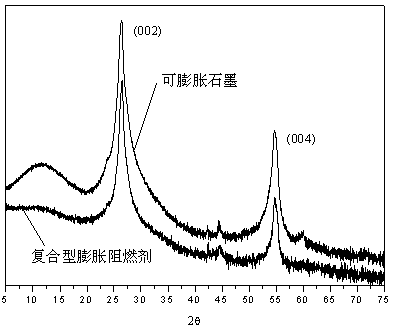

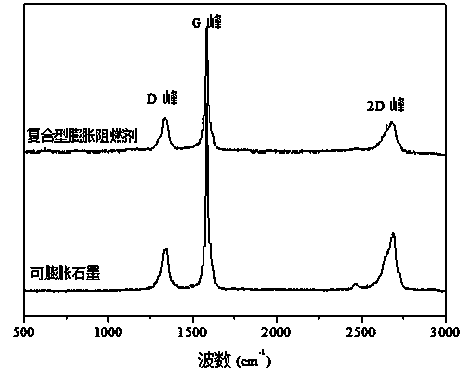

[0026] Add 5g of 80 mesh expandable graphite and 50g of dioxane into a three-necked flask, stir and mix evenly to obtain a suspension A of expandable graphite;

[0027] Add 2.58g of phosphorus oxychloride to 25.8g of dioxane to prepare solution B. Add solution B to suspension A to obtain mixed solution C; heat mixed solution C to 40°C, and react under nitrogen protection for 2 hours to obtain reaction solution D in which phosphorus oxychloride expandable graphite is formed;

[0028] According to the molar ratio of phosphorus oxychloride and pentaerythritol as 1:1, 2.29g of pentaerythritol was added to the above reaction solution D, and 0.0046g of anhydrous stannous chloride was added; the temperature was raised to 60°C for 4 hours to obtain reaction solution E. According to the pentaerythritol and 1,3,5-triglycidyl-S-triazinetrione molar ratio of 1:1, 5.63g of 1,3,5-triglycidyl-S-triazinetrione was added to the reaction solution In E, the temperature was raised to 80° C. for ...

Embodiment 2

[0040] Add 5g of 100 mesh expandable graphite and 50g of dioxane into a three-necked flask, stir and mix evenly to obtain a suspension A of expandable graphite;

[0041] Add 2 g of phosphorus oxychloride to 20 g of dioxane to prepare solution B. Add solution B to suspension A to obtain mixed solution C; heat mixed solution C to 50° C., and react under nitrogen protection for 1 hour to obtain reaction solution D in which phosphorus oxychloride expandable graphite is formed;

[0042] According to the molar ratio of phosphorus oxychloride and pentaerythritol as 1:1, 1.03g of pentaerythritol was added to the above reaction solution D, and 0.0021g of anhydrous stannous chloride was added; the temperature was raised to 70°C for 3 hours to obtain reaction solution E. According to the pentaerythritol and 1,3,5-triglycidyl-S-triazinetrione molar ratio of 1:1.5, 5.82g of 1,3,5-triglycidyl-S-triazinetrione was added to the reaction solution In E, the temperature was raised to 90°C for 1...

Embodiment 3

[0045] Add 5g of 320 mesh expandable graphite and 60g of dioxane into a three-necked flask, stir and mix evenly to obtain a suspension A of expandable graphite;

[0046] Add 1.85g of phosphorus oxychloride to 18.5g of dioxane to prepare solution B. Add solution B to suspension A to obtain mixed solution C; heat mixed solution C to 50° C., and react for 2 hours under nitrogen protection to obtain reaction solution D in which phosphoryl chloride-formed expandable graphite is formed;

[0047] According to the molar ratio of phosphorus oxychloride and pentaerythritol as 1:1, 1.64g of pentaerythritol was added to the above reaction solution D, and 0.0033g of anhydrous stannous chloride was added; the temperature was raised to 60°C for 2 hours to obtain reaction solution E. According to the pentaerythritol and 1,3,5-triglycidyl-S-triazinetrione molar ratio of 1:2, 7.17g of 1,3,5-triglycidyl-S-triazinetrione was added to the reaction solution In E, the temperature was raised to 80° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com