Preparation method of solid composite bonding material

A technology for bonding materials and solids, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve problems such as fire accidents, easy to obtain raw materials, good mechanical properties, and good curing effect at room temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] 100 g of bisphenol A cyanate resin monomer and 60 g of 2,4,6-trimethoxybenzyl acetal pentaerythritol carbonate monomer were reacted at 130° C. for 40 minutes to obtain a heat-resistant resin prepolymer.

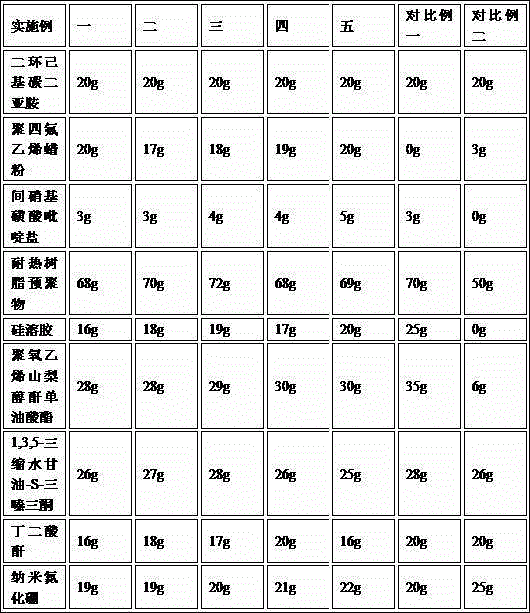

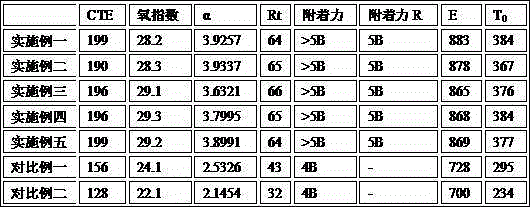

[0021] According to the proportions in Table 1, silica sol (solid content is 28%; particle size of silicon dioxide is 150-260 nanometers), polyoxyethylene sorbitan monooleate, 1,3,5-triglycidyl- S-triazinetrione was mixed for 2 hours to obtain a mixture; sequentially add succinic anhydride and nano-boron nitride (200-330 nanometers) into the mixture, stir for 4 hours, then add polytetrafluoroethylene wax powder, m-nitrosulfur acid pyridinium salt, stirred at 60°C for 8 hours; finally added dicyclohexylcarbodiimide and epoxy resin prepolymer, stirred at 105°C for 3 hours to obtain a compound; then put the compound into a mold, and molded (0.2 MPa; 90°C; molding for 30 seconds) to obtain a solid composite adhesive material.

[0022] Table 1 raw material quality

[0023...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com