Foam drilling fluid

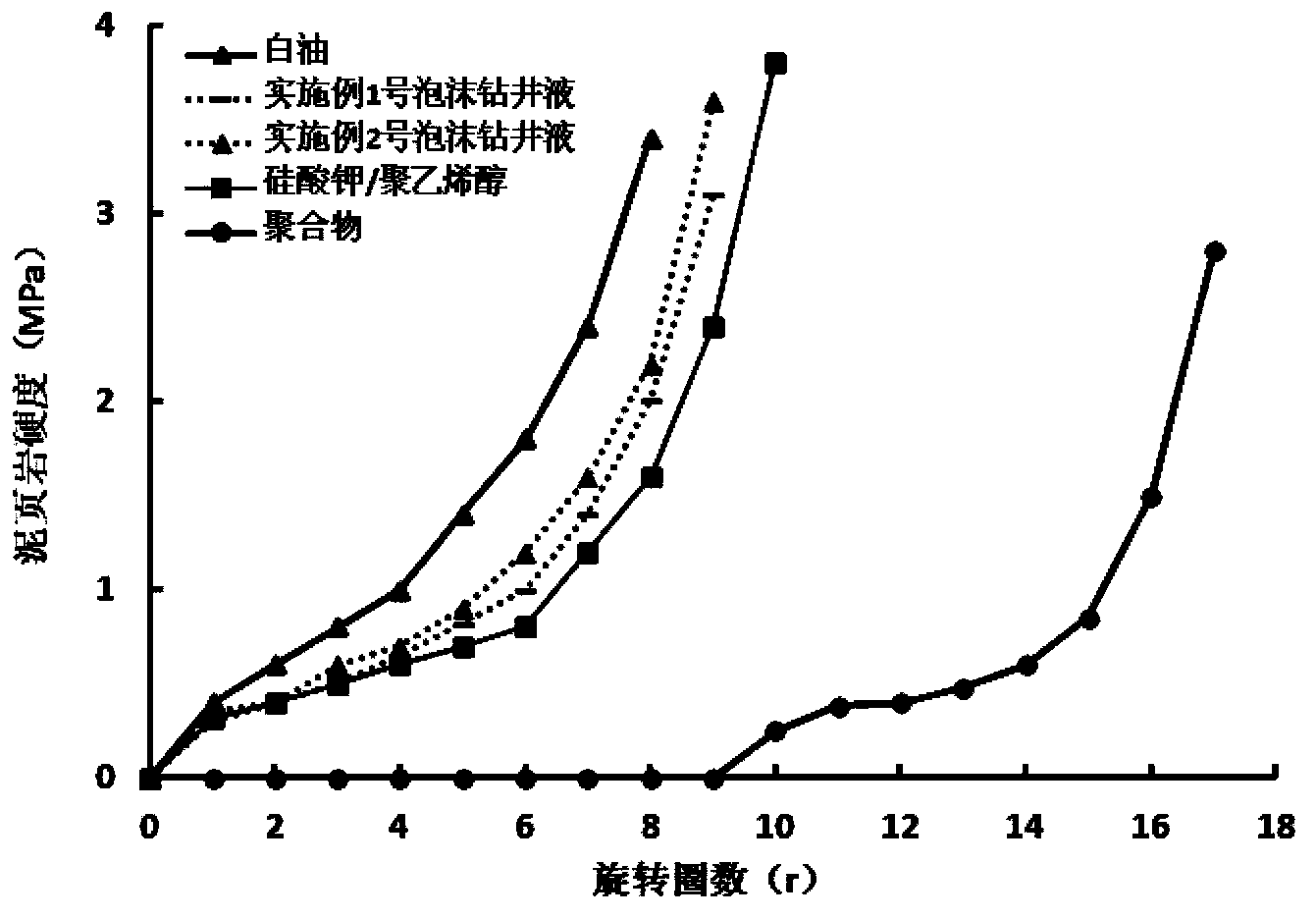

A drilling fluid and foam technology, applied in the field of foam drilling fluid, can solve the problem that the treatment agent does not have long-term inhibition performance, achieve long-term inhibition performance, reduce downhole complex situations, and have strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

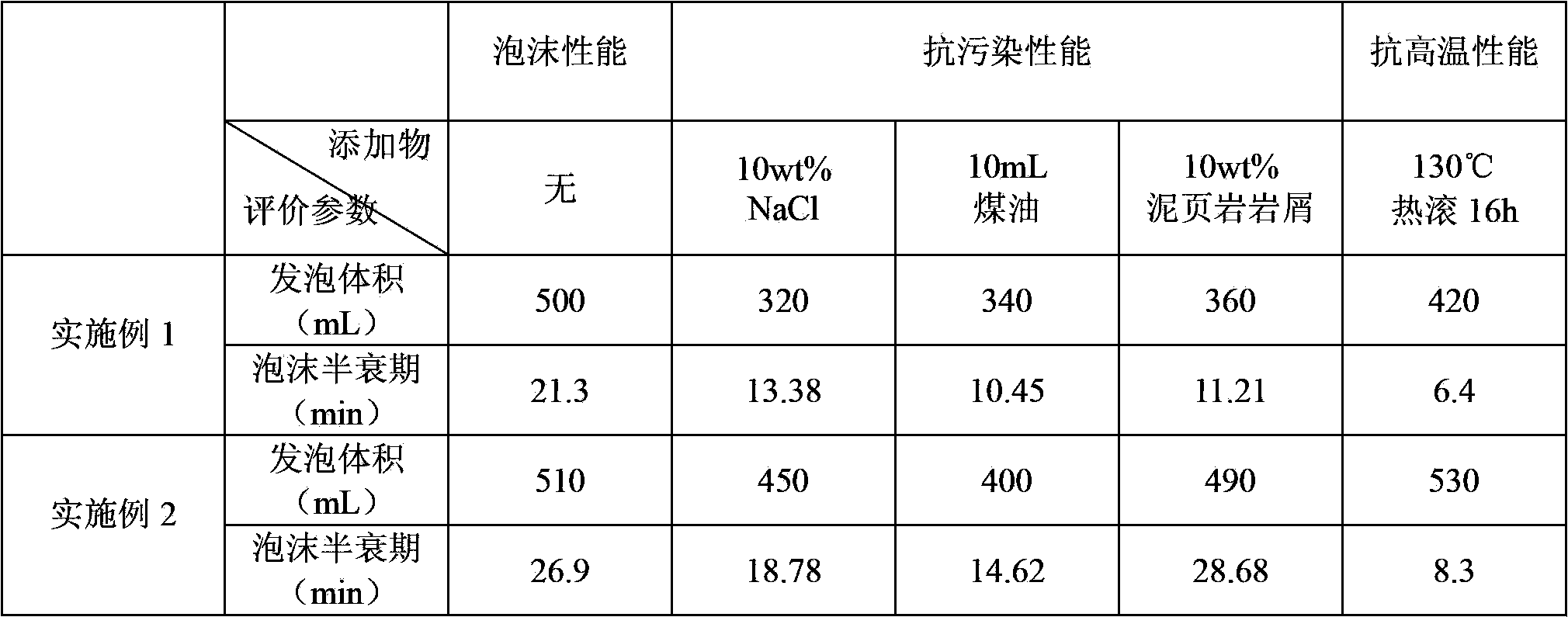

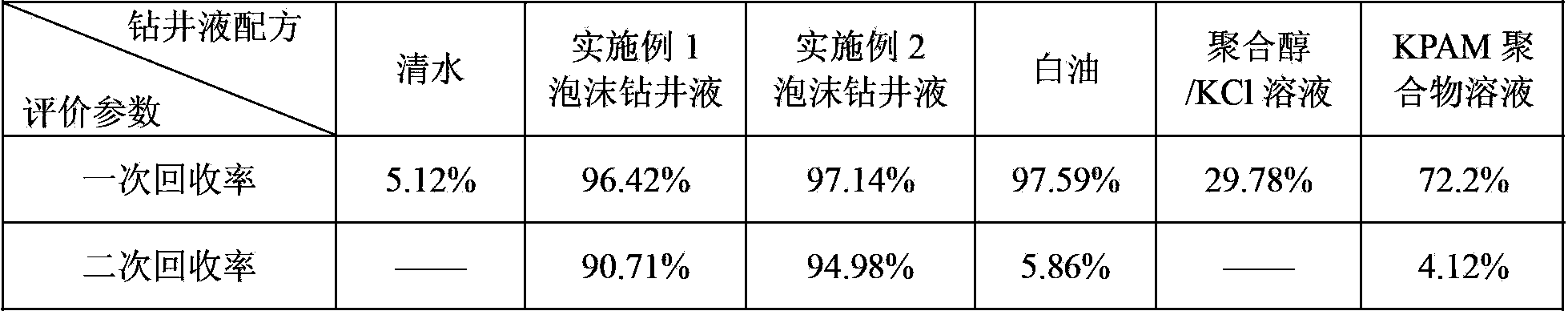

[0037] Embodiment 1 foam drilling fluid

[0038] The raw materials and mass ratio of foam drilling fluid are:

[0039] Blowing agent (CTAB) 1%,

[0040] Foam stabilizer (XC) 0.2%,

[0041] Shale inhibitor (choline chloride: polyoxyethylene diamine: polyetheramine: 4,4-diaminodicyclohexylmethane = 1:1:1.5:1.5 compound) 5%,

[0042] Shale stabilizer (hydrolyzed product after copolymerization of dimethylaminopropyl methacrylamide and vinyl acetate) 0.4%,

[0043] The balance is water, hydrochloric acid or sodium hydroxide solution to adjust the pH of the solution to 8-10.

[0044]Preparation method: Dissolve the foam stabilizer in water at normal temperature and pressure for more than 10 hours of prehydration treatment (prehydration treatment is to dissolve the polymer in water to make its molecular chain more stretchable, because this requires a certain Time, so let it stay in the water for about 10 hours), then weigh the raw materials according to the above ratio, add the f...

Embodiment 2

[0045] Embodiment 2 foam drilling fluid

[0046] The raw materials and mass ratio of foam drilling fluid are:

[0047] Foaming agent (AES: BS-12=1:4 compound) 1%,

[0048] Foam stabilizer (XC:CMC=2:1 compound) 0.3%,

[0049] Shale inhibitor (choline chloride: polyetheramine: 4,4-diaminodicyclohexylmethane = 2:2:1 compound) 5%,

[0050] Shale stabilizer (graft copolymer of methacryloylpropyltrimethylammonium chloride and polyvinyl alcohol) 0.5%,

[0051] The balance is water, hydrochloric acid or sodium hydroxide solution to adjust the pH of the solution to 8-10.

[0052] Preparation method: under normal temperature and pressure, first dissolve the foam stabilizer in water for more than 10 hours of prehydration treatment, then weigh the raw materials according to the above ratio, stir the foam stabilizer, foaming agent, and mud shale to suppress Add the agent and shale stabilizer into water, mix and stir evenly, and adjust the pH to 8-10 to obtain the foam drilling fluid of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com