Chemical-looping combustion device and use method thereof

A technology of chemical looping combustion and fluidized bed, which is applied in the field of chemical looping system, can solve problems such as increasing system economic investment, difficulty in satisfying long residence time of particles, system design, difficulty in operation control, etc., to prolong residence time and effectively Particle residence time, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

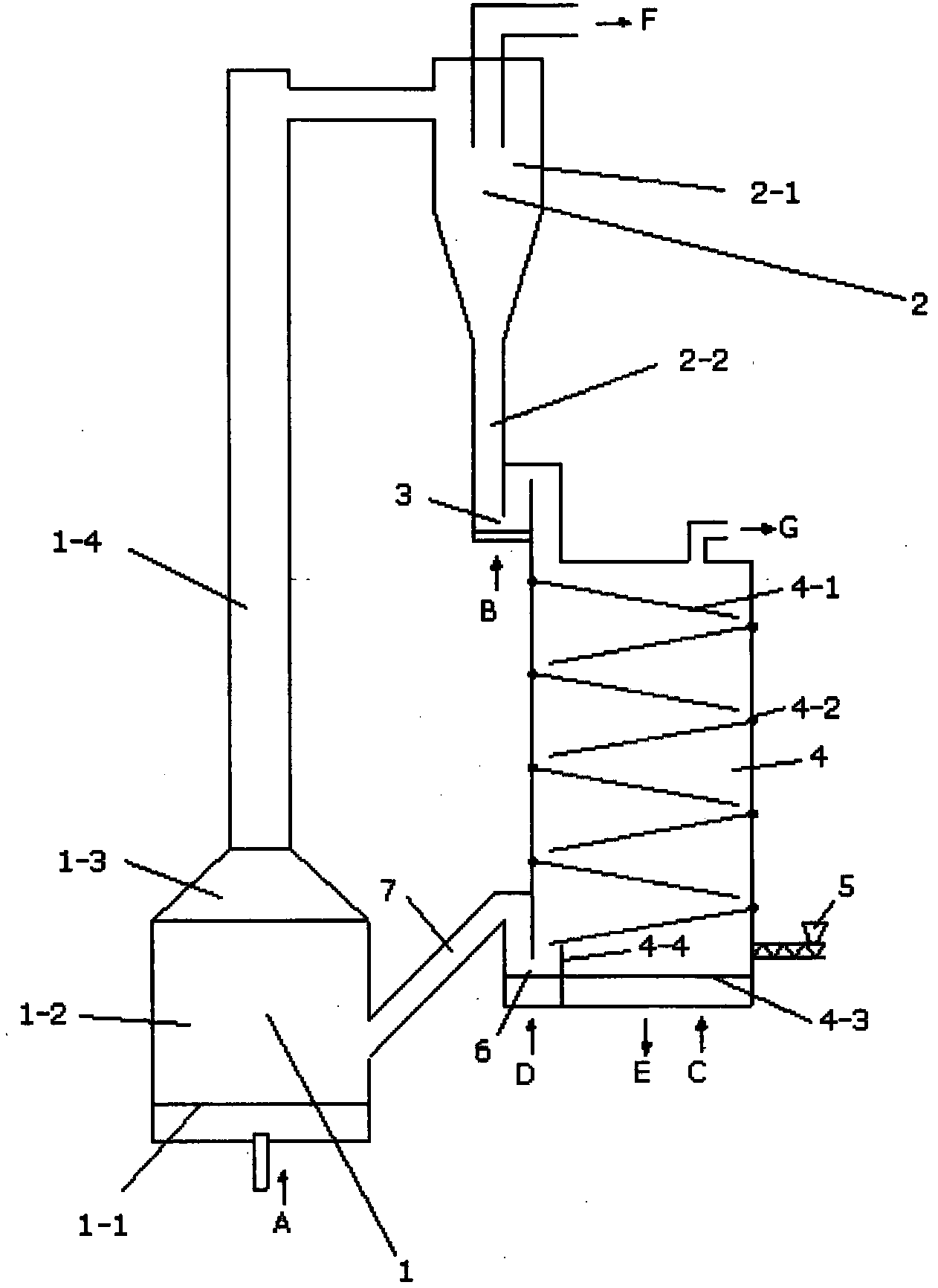

[0030] figure 1 A schematic diagram of a chemical looping combustion device provided by the present invention, said a kind of chemical looping combustion device includes an air reactor fluidized bed 1, the main functional structure of the air reactor fluidized bed 1 includes successively decreasing cross-sectional areas Air reactor main chamber 1-2, air reactor transition section 1-3 and air reactor riser 1-4. The air distribution plate 1-1 of the air reactor is located below the main air reaction chamber 1-2, and the air reactor riser 1-4 is installed above the main air reaction chamber 1-2 through the transition section 1-3 of the air reactor.

[0031] The cyclone separator 2 is connected with the fluidized bed 1 of the air reactor. The cyclone separator 2 comprises a gas-solid separator 2-1 and a cyclone separator downcomer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com