PACT process for reducing sludge discharge and recycling activated carbon

A kind of activated carbon and process technology, applied in the field of PACT process, can solve the problems of high cost, unfavorable PACT process operation cost, complicated operation, etc., and achieve the effect of simple operation, improved overall treatment effect, and increased residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This example is used to illustrate the PACT process of the present invention for reducing sludge discharge and recycling activated carbon.

[0052] The basic situation of the wastewater to be treated: the wastewater is produced by an oil refinery, the COD is 550-650mg / L, the BOD is 230-350mg / L, the ammonia nitrogen is 25-35mg / L, the oil content is 16-32mg / L, and the suspended solid content 100-200mg / L.

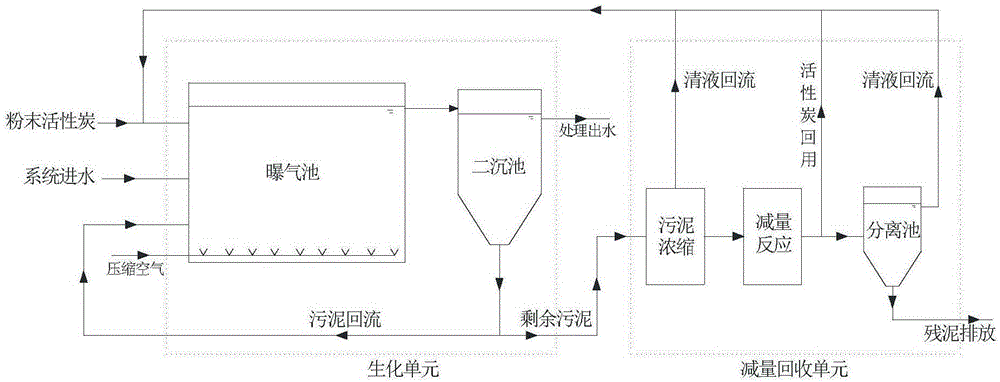

[0053] according to figure 1 The process flow shown is to treat the wastewater to be treated. The wastewater to be treated is aerated in the aeration tank of the biochemical unit under the joint action of activated carbon and microorganisms. Compared with the system influent, the dosage of fresh powdered activated carbon in the aeration tank is 40mg / L, and the hydraulic retention of the aeration tank The time is 12 hours, and the water temperature in the aeration tank is 20-25°C; the effluent after aeration treatment in the aeration tank enters the secondary sedimenta...

Embodiment 2

[0056] This example is used to illustrate the PACT process of the present invention for reducing sludge discharge and recycling activated carbon.

[0057] The basic situation of the wastewater to be treated: the wastewater is produced by an oil refinery, the COD is 280-400mg / L, the BOD is 130-220mg / L, the ammonia nitrogen is 20-30mg / L, the oil content is 15-25mg / L, and the suspended solid content 100-150mg / L.

[0058] according to figure 1 The process flow shown is to treat the wastewater to be treated. The wastewater to be treated is aerated in the aeration tank of the biochemical unit under the joint action of activated carbon and microorganisms. Compared with the system influent, the dosage of fresh powdered activated carbon in the aeration tank is 30mg / L, and the hydraulic retention of the aeration tank The time is 8 hours, and the water temperature in the aeration tank is 20-25°C; the effluent after aeration treatment in the aeration tank enters the secondary sedimentat...

Embodiment 3

[0061] This example is used to illustrate the PACT process of the present invention for reducing sludge discharge and recycling activated carbon.

[0062] The basic situation of the wastewater to be treated: the wastewater is produced by a chemical enterprise, the COD is 1200-1600mg / L, the BOD is 380-680mg / L, the ammonia nitrogen is 32-42mg / L, the oil content is 18-35mg / L, and the suspended matter content It is 150-300mg / L.

[0063] according to figure 1 The process flow shown is to treat the wastewater to be treated. The wastewater to be treated is aerated in the aeration tank of the biochemical unit under the joint action of activated carbon and microorganisms. Compared with the system influent, the dosage of fresh powdered activated carbon in the aeration tank is 50mg / L, and the hydraulic retention of the aeration tank The time is 30 hours, and the water temperature in the aeration tank is 20-25°C; the effluent after aeration treatment in the aeration tank enters the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com