CORDIC (coordinate rotation digital computer) accelerator based on parallel pipeline design

A pipeline and accelerator technology, applied in the field of calculators and calculators for fast calculation of transcendental functions, can solve the problems of large area, low precision, low cost, etc., and achieve large throughput, small delay, and small overall volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

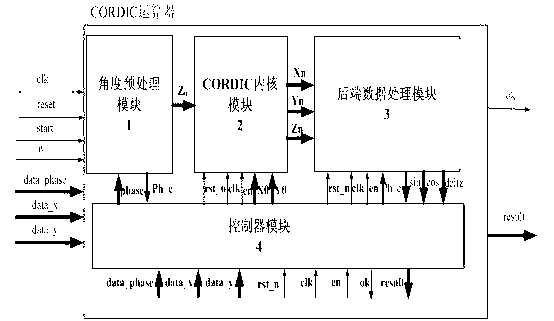

[0026] Such as figure 1 As shown, the CORDIC accelerator based on the parallel pipeline design of the present invention includes: an angle preprocessing module (1), a CORDIC kernel module (2), a data back-end processing module (3) and a controller module (4). It is characterized in that the external data lines and control lines are first read in the relevant data signals and control signals to the controller module (4), and then the angle to be requested is transmitted to the angle preprocessing module (1), and then the processed angle The initial value read from the controller module (4) is sent to the CORDIC kernel module (2), and the CORDIC kernel module (2) adopts a parallel pipeline structure to quickly calculate the sine sum of the angle after passing through the angle preprocessing module (1) The two values of cosine are then sent to the back-end data processing module (3) together with the calculated data and the phase control signal output from the controller module...

Embodiment 2

[0028] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

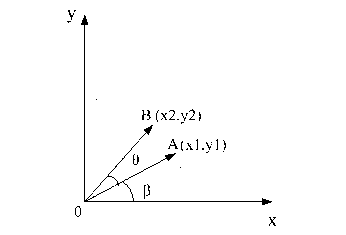

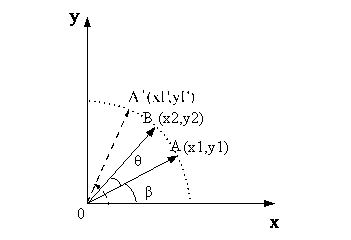

[0029] For the CORDIC algorithm under the circular rotation mode adopted by the present invention, Fig. 2 is a plane coordinate rotation completed by the circular system of the CORDIC algorithm. Among them, Figure 2.a shows that from the original point A (x1, y1), after the rotation angle θ, it reaches the target point B (x2, y2), and Figure 2.b shows that after the first CORDIC angle rotation, Reach A'(x1',y1'), Figure 2.c shows that after the second CORDIC angle rotation, A"(x1",y1") is reached, after multiple rotations, An will approach the target point B .

[0030] , CORDIC kernel module

[0031] see Figure 4 , this module is implemented with a parallel, 16-stage pipeline structure, which improves the computing throughput. Each stage consists of two 32-bit iterations and one 32-bit register, see Figure 5 , using 32 iterations to make the accuracy of the entire op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com