Compression device for artificial valve replacement device

一种瓣膜置换、压缩装置的技术,应用在心脏瓣膜、医药科学、假体等方向,能够解决清洁和灭菌的难度大、外廓尺寸大、制造成本高等问题,达到结构简单、制作成本降低、操作方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

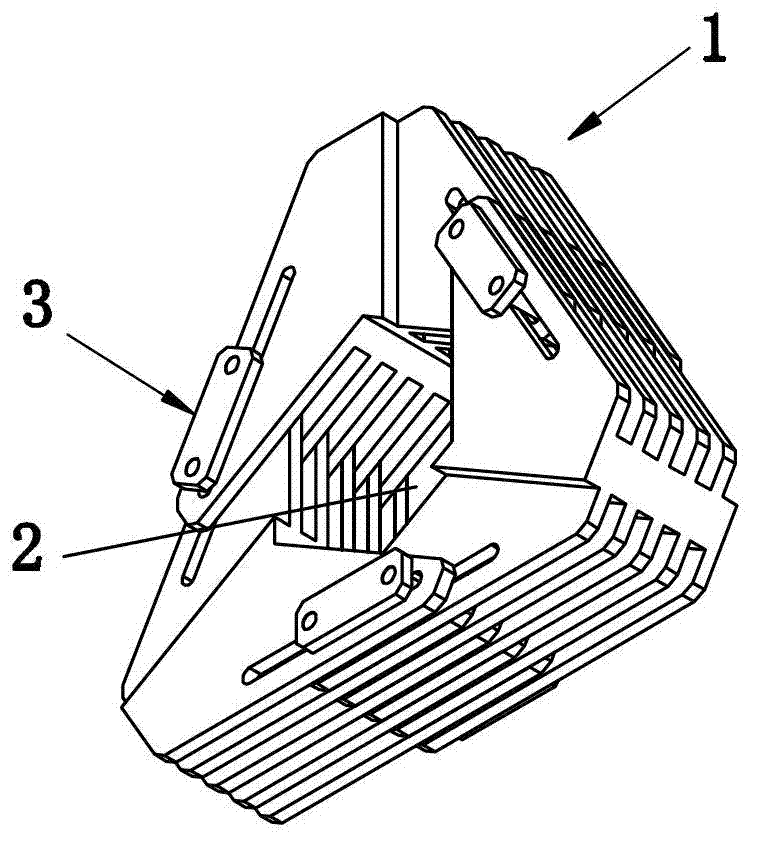

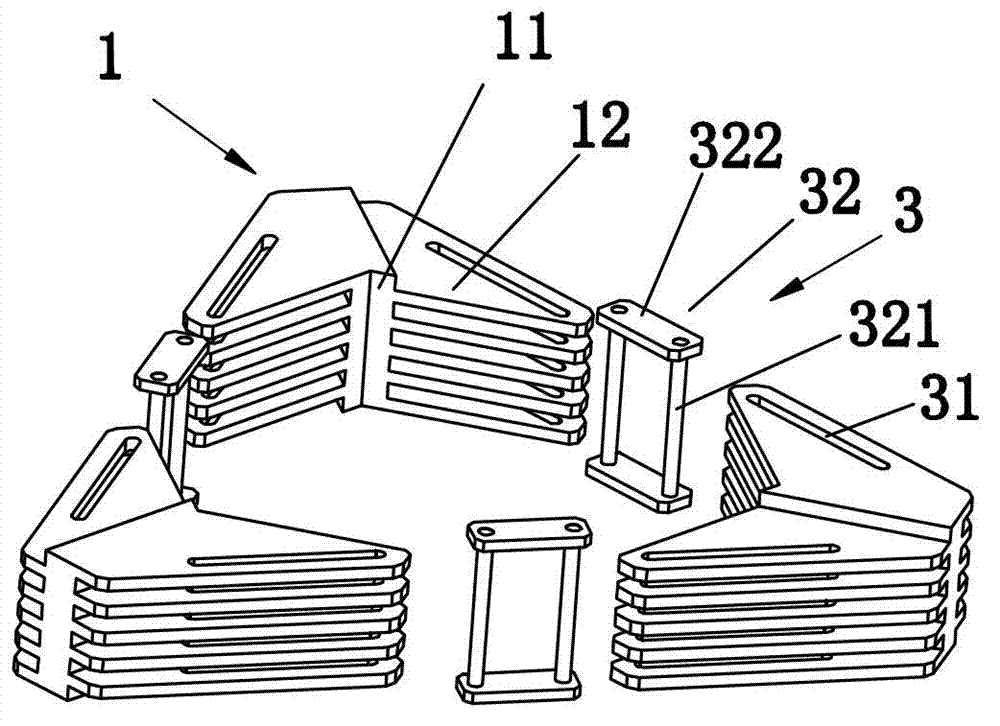

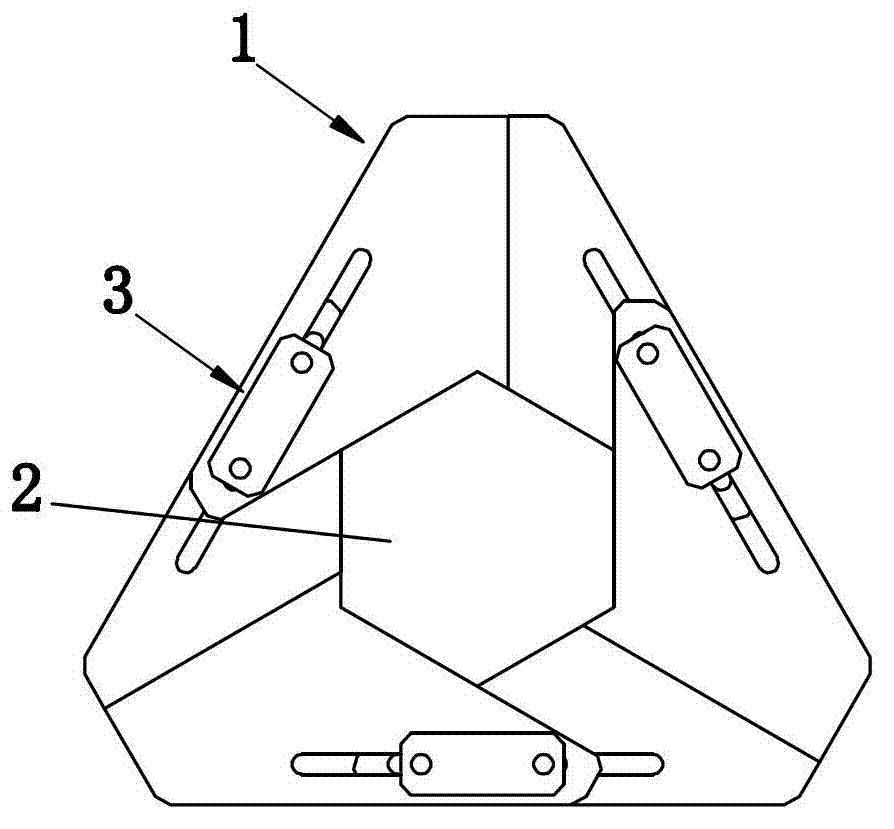

[0038] Embodiment one: if Figure 1-5 As shown, the present embodiment includes three clamping unit blocks 1, the clamping unit block 1 consists of a connecting portion 11, and comb-shaped connecting arms 12 fixed on both sides of the connecting portion 11, and the comb-like structure of the connecting arms 12 The upper row of combs is arranged along the axis of the scaling channel 2. The three clamping unit blocks 1 are sequentially connected by connecting arms 12 to form a closed ring structure. The center of the ring structure is a zoom channel 2, and two adjacent connecting arms 12 are staggered and interspersed to form a sliding fit. The row comb structure of the connecting arm 12 is a plurality of plate-like comb teeth 121 arranged in parallel, each comb tooth 121 is arranged axially along the zoom channel 2, then, that is, the side of the clamp unit block 1 facing the zoom channel 2 It is the gap between adjacent comb teeth 121 arranged in parallel, and the gap can ens...

Embodiment 2

[0044] Embodiment two: if Figure 6-8 As shown, the present embodiment includes two clamping unit blocks 1a, the clamping unit block 1a is composed of a connecting portion 11a, and a row of comb-shaped connecting arms 12a fixed on both sides of the connecting portion 11a, and a row of comb-like structures of the connecting arms 12a The upper row of combs is arranged along the axial direction of the zoom channel 2a. The two clamping unit blocks 1a are sequentially connected by connecting arms 12a to form a closed ring structure. The center of the ring structure is a zoom channel 2a, and two adjacent connecting arms 12a are staggered and interspersed to form a sliding fit.

[0045] In order to realize the motion control of the clamping unit block 1a, a guide structure 3a is provided between two adjacent connecting arms, and the guiding structure 3a guides the clamping unit block 1a to converge towards the center of the zoom channel 2a. There are a total of two guide structures ...

Embodiment 3

[0048] Embodiment three: as Figure 9-11 As shown, the present embodiment includes four clamping unit blocks 1b, the clamping unit block 1b consists of a connecting portion 11b, and comb-shaped connecting arms 12b fixed on both sides of the connecting portion 11b, and the comb-like structure of connecting arms 12b The upper row of combs is arranged along the axial direction of the zoom channel 2b. The four clamping unit blocks 1b are sequentially connected by connecting arms 12b to form a closed ring structure. The center of the ring structure is a scaling channel 2b, and two adjacent connecting arms 12b are staggered and interspersed to form a sliding fit.

[0049] In order to realize the motion control of the clamping unit block 1b, a guide structure 3b is provided between two adjacent connecting arms, and the guiding structure 3b can guide the clamping unit block 1b to converge toward the center of the zoom channel 2b. There are four guide structures 3b in total, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com