Multifunctional composite filtering diaphragm plate

A composite filtration and multi-functional technology, applied in the direction of membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of poor effluent quality, low filling density, easy to adhere to pollutants, etc., and achieve equipment filling density Improvement, elimination of sealing leakage, simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

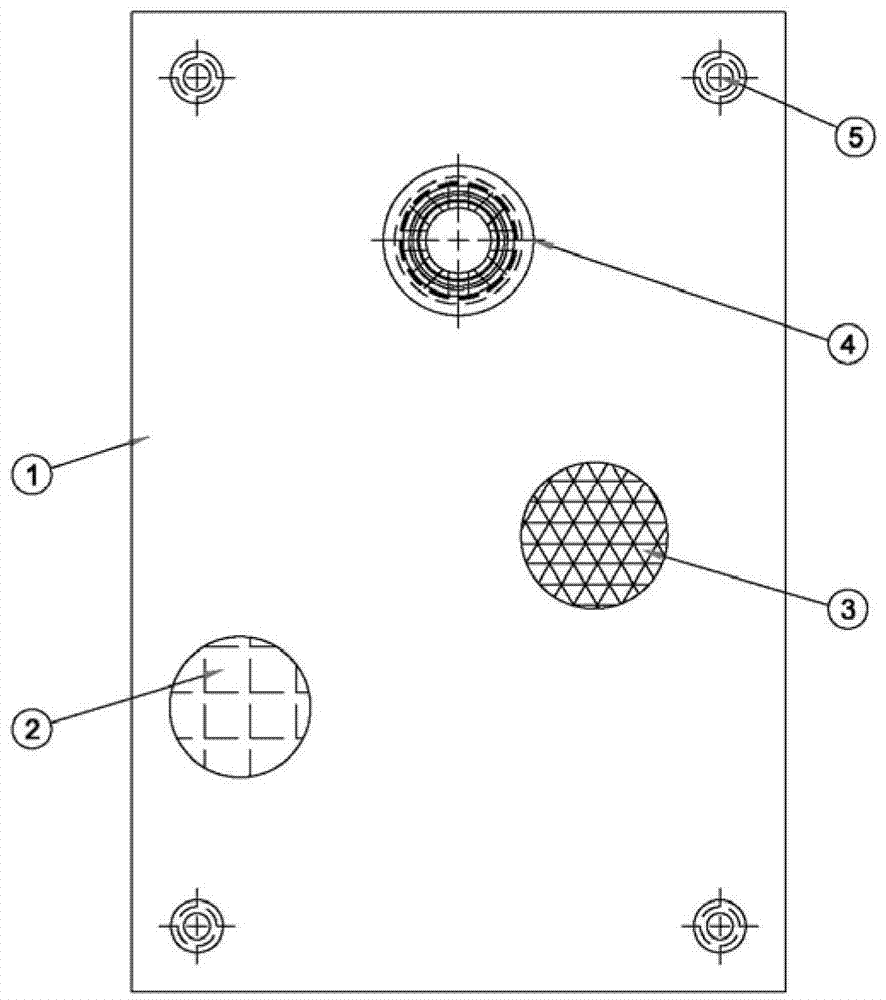

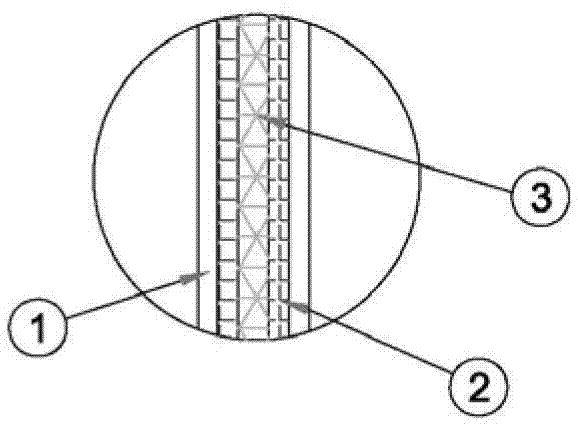

[0025] See attached Figure 1~3 , the present invention consists of two filter membranes 1, two support layer non-woven fabrics 2, flow channel grid 3 and dialysate collection ring 4, etc., the flow channel grid 3 is bonded to the two support layer non-woven fabrics 2 In the middle, the filter membranes 1 are bonded to the outer surfaces of the support layer 2 respectively.

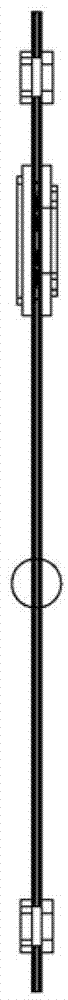

[0026] In order to facilitate the collection of the dialysate, the present invention provides a dialysate collection port on the top of the membrane plate, which together with the collection ring 4 completes the function of collecting and drawing out the dialysate. see figure 2 , the collection ring 4 is two discs with an opening in the middle, which are respectively set on the two ends of the collection hole, and the openings of the discs are aligned with the collection hole.

[0027] In order to facilitate the installation and fixing of the entire diaphragm, the four corners of the diaphragm of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com