Fluid-bed separator comprising vibrating air distribution plate

A fluidized bed and air distribution plate technology, which is applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problem of affecting the stability of equipment structures, destroying bed transmission structures, and transmission structures. Complicated problems, to achieve the effect of reducing unit energy consumption, simple and effective transmission structure, and improving fluidization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

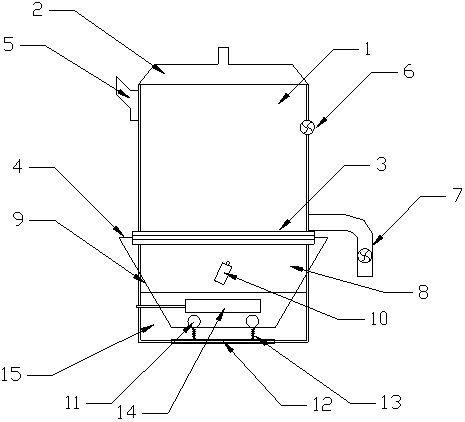

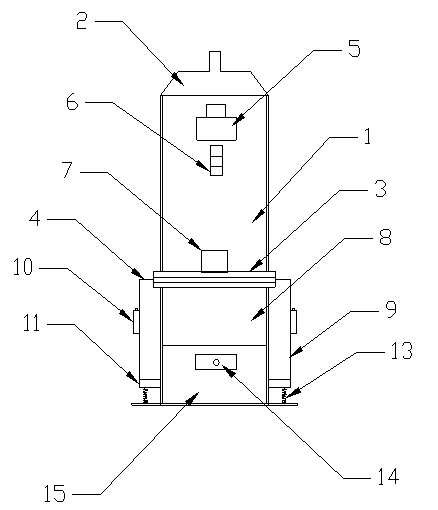

[0010] A kind of embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0011] The air distributor vibrating fluidized bed of the present invention mainly includes a fluidized bed shell 1, a feeding hopper 5, a light product discharge port 6, a heavy product discharge port 7, a dust removal sealing cover 2, a fixed frame 3, Vibrating air distribution plate 4, trapezoidal steel plate 9, vibrator 10, voltage stabilizing air distribution chamber 8, beam 11, floor mat base 12, gas pre-distributing device 14, base 15 are composed. The dust removal sealing cover 2 is set on the fluidized bed shell 1, the feeding hopper 5 is set on the upper part of one side of the fluidized bed shell 1, and the light product discharge port 6 is set on the upper part of the other side of the fluidized bed shell 1. The height difference and the impeller make the light products uniformly discharged, and the heavy product discharge port 7 is set a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com